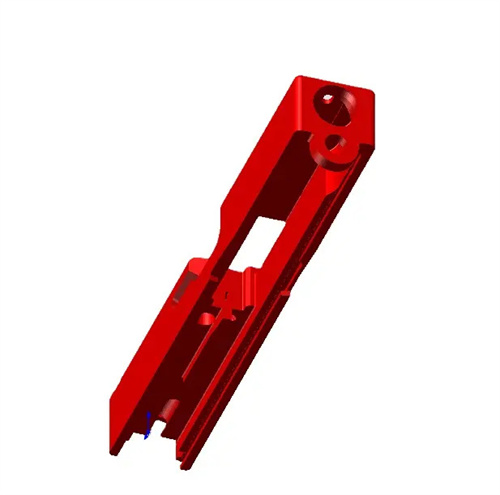

Metal Steel CNC Machining

Our Metal Steel CNC Machining has the dual advantages of high precision and high efficiency. Relying on advanced CNC machining equipment, such as five axis linkage CNC machine tools and high-precision servo drive systems, it can achieve micrometer level machining accuracy for metal and steel materials, with positioning errors controlled within ± 0.005mm and repeated positioning accuracy of ± 0.002mm. It can perfectly process complex surfaces, deep cavities, and precise hole structures. In terms of processing efficiency, automated production processes combined with intelligent programming systems can automatically optimize tool paths and cutting parameters based on the characteristics of steel, resulting in an efficiency improvement of over 60% compared to traditional processing methods. For example, when processing high-strength steel components for large mechanical equipment, multiple processes are completed through one clamping, which not only ensures the dimensional accuracy of each part, but also greatly shortens the production cycle and efficiently meets customer delivery needs.

Metal Steel CNC Machining Steel Selection

In terms of material selection, we provide our customers with a wide range of metal and steel options. Ordinary carbon structural steel, such as Q235, has good plasticity and weldability, and is commonly used to manufacture structural components with low strength requirements, such as brackets, bases, etc; High quality carbon structural steel, such as 45 # steel, can obtain good comprehensive mechanical properties after heat treatment and is widely used in mechanical parts such as shafts and gears; Alloy structural steel, such as 40Cr, has improved strength, toughness, and wear resistance by adding alloying elements, making it suitable for manufacturing critical components that can withstand large loads and impacts; Stainless steel series, such as 304 and 316L, are indispensable in equipment manufacturing in food, chemical, medical and other fields due to their excellent corrosion resistance; High strength alloy steel, such as manganese steel and chromium molybdenum steel, has extremely high strength and hardness, and is commonly used as the core component of mining machinery and heavy engineering machinery. All steel is purchased from well-known domestic and foreign steel mills, with material certification attached to each batch, and undergoes strict testing such as spectral analysis and tensile testing to ensure that the material quality meets the standards.

The production process of Metal Steel CNC Machining

We have established a rigorous and orderly Metal Steel CNC Machining production process. Firstly, the technical team uses professional CAD/CAM software for 3D modeling and programming based on the drawings or design schemes provided by the customer, converts the design requirements into instruction codes recognizable by the CNC machine tool, and develops a detailed machining process route. Next, the operator fixes the metal steel blank on the CNC machine tool and accurately sets the tool parameters through the tool setter to ensure the accurate starting position of the machining. During the machining process, the real-time monitoring system dynamically monitors key parameters such as cutting force, spindle speed, and feed rate. Once the parameters are abnormal, the system automatically alarms and adjusts the machining parameters to prevent tool wear and part scrap. For parts with high precision requirements, rough machining is used to remove most of the excess, semi precision machining is used to further correct the size, and precision machining is carried out in a step-by-step manner to achieve the final precision requirements. After processing, it is necessary to carry out post-processing procedures such as deburring, cleaning, rust prevention, etc. to ensure that the product meets the delivery standards.

Surface treatment of Metal Steel CNC Machining

We offer a variety of surface treatment processes to enhance the performance and appearance of metal steel machined parts. Electroplating processes, such as galvanizing and chrome plating, can form a dense metal protective layer on the surface of steel, effectively enhancing rust prevention ability and surface hardness, while giving the parts a bright metallic texture; Blackening treatment can generate a black oxide film on the surface of steel, improving the corrosion resistance and wear resistance of parts, and is commonly used for internal structural components; The spray painting process adopts electrostatic spraying technology to evenly adhere the coating, which not only protects the steel from environmental erosion, but also achieves diversified appearance colors according to customer needs; Hot dip galvanizing treatment is suitable for large steel components. By immersing the steel in molten zinc, a strong zinc iron alloy layer is formed, significantly improving the corrosion resistance of the components and extending their service life. In addition, for parts with special requirements, we also provide surface treatment methods such as sandblasting, polishing, and passivation to meet the requirements of different application scenarios.

Dimensional Inspection of Metal Steel CNC Machining

In the dimension inspection process, we are equipped with advanced testing equipment and a professional quality inspection team to implement strict and accurate quality inspection standards. The coordinate measuring instrument can measure metal and steel processing parts in three-dimensional space in all directions, with a measurement accuracy of up to 0.001mm. It can accurately capture complex surface contours, as well as small aperture and groove widths; The image measuring instrument uses a high-definition imaging system to quickly and accurately measure the two-dimensional contour of the parts; Hardness tester is used to test the hardness of steel parts to ensure that the material properties meet the requirements; The surface roughness meter can measure the microscopic morphology of the surface of parts, ensuring surface quality. We strictly follow the ISO 9001 quality management system standard, conduct sampling inspections on each batch of products, and conduct full inspections on key components. Once any dimensional deviation, hardness non-compliance, or surface quality issues are discovered, the traceability program should be immediately initiated to analyze the cause and adjust the processing technology, reprocessing until the product is qualified, ensuring that every delivered part has reliable quality.

Application of Metal Steel CNC Machining Products

Our Metal Steel CNC Machining products are widely used in multiple fields. In the mechanical manufacturing industry, the core components used to produce various types of mechanical equipment, such as machine tool beds, guide rails, transmission gears, shaft parts of construction machinery, etc., provide guarantees for the stable operation of mechanical equipment; In the field of automobile manufacturing, processing automobile engine cylinder blocks, chassis structural components, suspension system parts, etc., helps improve the performance and safety of automobiles; In the energy industry, the manufacturing of turbine blades, pressure vessels, pipeline connectors, etc. for power generation equipment meets the requirements of energy production for equipment reliability and durability; In addition, it is also applied in industries such as mold manufacturing, rail transportation, and shipbuilding, providing key support for the development of various industries in metal and steel processing components.