In the dynamic and competitive packaging industry, CNC machining services have emerged as a transformative force, enabling us to create high – quality, customized, and efficient packaging solutions. These services, characterized by their computer – controlled precision and versatility, allow us to fabricate a wide range of components with intricate designs and exacting tolerances. From producing durable packaging molds to crafting unique decorative elements, CNC machining services play an indispensable role in our efforts to meet the diverse needs of the market, enhance product protection, and elevate the visual appeal of packages. They have seamlessly integrated into our production processes, empowering us to stay ahead in an industry that constantly demands innovation and excellence.

1. CNC Machining Services: Fabricating High – Precision Packaging Molds

One of the primary applications of CNC machining services in the packaging industry is the fabrication of high – precision packaging molds. Molds are crucial for mass – producing packaging components such as plastic containers, blister packs, and cardboard boxes with consistent quality. We rely on CNC machining to create molds from materials like steel, aluminum, and copper, ensuring precise cavity and core shapes that match the intended packaging design.

For example, in the production of plastic bottles for the beverage industry, CNC – machined molds are used to form the bottles with accurate dimensions and smooth surfaces. The high – speed and high – accuracy of CNC milling and turning processes allow us to create complex mold geometries, including threads for bottle caps and intricate logos or patterns on the bottle body. This precision ensures that the molded plastic bottles fit snugly with caps and labels, providing a secure seal and an appealing appearance. Additionally, CNC – machined molds can be easily modified and replicated, enabling us to quickly adapt to design changes and produce packaging components in large quantities.

2. CNC Machining Services: Creating Customized Packaging Components

CNC machining services also excel at creating customized packaging components that meet specific client requirements. Whether it’s for luxury product packaging, promotional items, or specialized industrial packaging, we can use CNC machining to fabricate unique parts from various materials. For instance, in the production of high – end gift boxes, CNC – machined wooden or metal inserts can be customized to hold delicate products securely in place.

The flexibility of CNC machining allows us to create components with complex shapes, precise cutouts, and detailed engravings. In the case of promotional packaging, we can use CNC – controlled laser cutting to produce custom – shaped cardboard inserts or acrylic displays with the client’s logo and branding elements. These customized components not only enhance the protection of the packaged products but also add a touch of exclusivity and personalization, making the packaging more appealing to consumers.

3. CNC Machining Services: Producing Packaging Machinery Parts

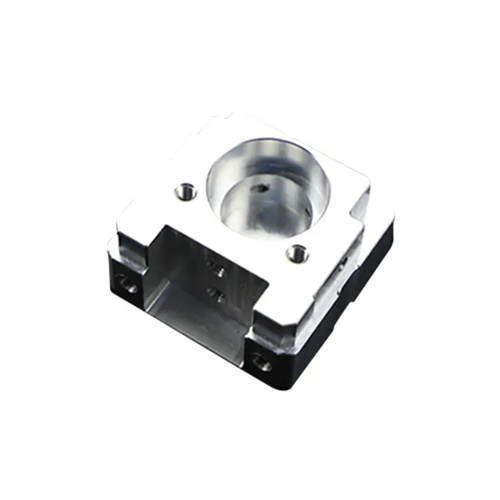

Packaging machinery requires reliable and precisely – engineered parts to operate efficiently, and CNC machining services are essential for producing these components. We use CNC machining to fabricate parts such as gears, shafts, bearings, and conveyor components from metals and high – performance plastics. The precision of CNC machining ensures that these parts fit together seamlessly, reducing friction and wear, and improving the overall performance and lifespan of the packaging machinery.

For example, in the production of filling and sealing machines, CNC – machined gears and shafts are crucial for accurate and smooth operation. The tight tolerances achieved through CNC machining guarantee that the gears mesh correctly, transmitting power efficiently without any slippage. Similarly, CNC – machined conveyor components, such as rollers and belts, are designed to handle the movement of packages with precision, preventing jams and ensuring a continuous production flow. By using CNC – machined parts in packaging machinery, we can enhance productivity, reduce maintenance costs, and minimize downtime.

4. CNC Machining Services: Enhancing Packaging Aesthetics with Decorative Elements

Aesthetic appeal is an important aspect of packaging, and CNC machining services can be used to create decorative elements that enhance the visual attractiveness of packages. We can use CNC – controlled laser engraving and cutting to produce intricate patterns, logos, and text on various packaging materials, including paper, cardboard, metal, and plastic. These decorative elements can transform a simple package into an eye – catching display piece.

For example, in the packaging of cosmetics and beauty products, CNC – engraved metal caps and labels add a touch of elegance and luxury. The precision of laser engraving allows for the creation of fine details and gradients, giving the packaging a high – end look. In addition, CNC – cut window frames on cardboard boxes can be used to showcase the product inside, creating an inviting and interactive packaging experience for consumers. These aesthetic enhancements not only make the packaging more appealing but also help to strengthen brand identity and increase product visibility on the shelves.

5. CNC Machining Services: Driving Innovation in Sustainable Packaging

As sustainability becomes a key focus in the packaging industry, CNC machining services are driving innovation in the development of eco – friendly packaging solutions. We can use CNC machining to optimize the design of packaging components, reducing material waste and improving recyclability. For example, CNC – machined molds can be designed to minimize the amount of material used in the production of packaging, while still maintaining structural integrity.

In addition, CNC machining enables the use of sustainable materials, such as recycled plastics and biodegradable composites, in packaging production. By precisely machining these materials, we can create packaging components that meet the same performance standards as traditional materials. Furthermore, CNC – machined parts can be designed for easy disassembly, facilitating the recycling process. Through continuous exploration and application of CNC machining services in sustainable packaging, we can contribute to a more environmentally friendly future for the packaging industry.