In the rapidly evolving and highly competitive landscape of electronic products, CNC machining services have become an indispensable cornerstone for achieving precision, innovation, and superior quality. These services, characterized by their computer – numerical control and ability to execute complex machining operations with meticulous accuracy, empower us to create components that meet the exacting demands of modern electronics. From crafting intricate casings for smartphones to producing high – precision parts for high – end computing devices, CNC machining services play a pivotal role in our pursuit of developing cutting – edge electronic products that combine functionality, durability, and aesthetic appeal. They have seamlessly integrated into our manufacturing processes, enabling us to stay ahead in an industry that constantly pushes the boundaries of technological advancement.

1. CNC Machining Services: Fabricating Precision Electronic Enclosures

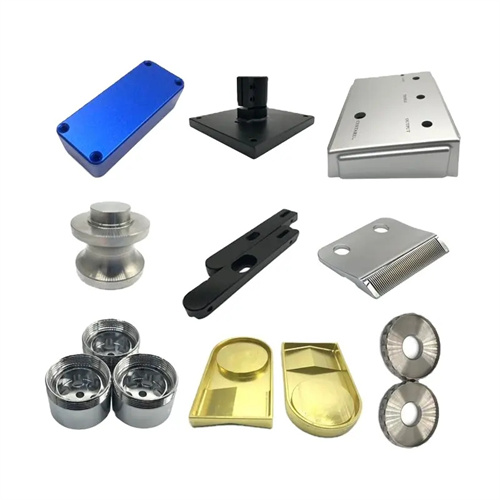

One of the primary applications of CNC machining services in electronic products is the fabrication of precision enclosures. In an era where the sleek design and ergonomic feel of electronics are highly valued, enclosures serve as the first impression of a product. We utilize CNC machining to create enclosures from materials such as aluminum alloy, stainless steel, and engineering plastics, ensuring precise dimensions and a perfect fit for internal components.

For example, in the production of high – end smartphones, CNC – machined aluminum alloy casings are meticulously crafted. The high – speed and high – precision nature of CNC milling and turning processes allow for the creation of ultra – thin yet sturdy enclosures with smooth curves and sharp edges. Precise cutouts for buttons, ports, and cameras are made with micrometer – level accuracy, ensuring that external accessories fit seamlessly. Additionally, the surface finish achieved through CNC machining can be customized, whether it’s a matte anodized finish for a premium look or a polished surface for a glossy appearance. These precision – fabricated enclosures not only protect the delicate internal circuitry but also enhance the overall user experience.

2. CNC Machining Services: Producing High – Precision Electronic Components

CNC machining services are crucial for producing a wide range of high – precision electronic components. From connectors and heat sinks to intricate internal brackets, these components require exacting tolerances to ensure optimal performance. We use CNC machining to manufacture components from materials like copper, brass, and specialized alloys, leveraging the technology’s ability to create complex geometries.

In the case of heat sinks for laptops and gaming consoles, CNC – machined fins are designed with a high degree of precision. The spacing, thickness, and shape of each fin are carefully controlled to maximize the surface area for heat dissipation while maintaining structural integrity. For connectors, CNC machining enables the production of parts with precise pin configurations and contact surfaces, ensuring stable electrical connections. These high – precision components, crafted through CNC machining, are essential for the reliable operation of electronic devices, reducing the risk of malfunctions and enhancing overall product performance.

3. CNC Machining Services: Crafting Custom – Designed Electronic Parts

The flexibility of CNC machining services allows us to create custom – designed electronic parts tailored to specific product requirements. Whether it’s a unique adapter for a specialized device or a custom – shaped bracket for a limited – edition gadget, CNC machining can bring our designs to life. We work closely with our design teams to translate concepts into reality, using the precision and versatility of CNC machining.

For instance, in the development of wearable electronics, custom – designed casings and mounting structures are often required to fit the unique form factors. CNC machining enables us to produce parts with complex 3D shapes that are not only functional but also aesthetically pleasing. The ability to quickly iterate on designs through CNC prototyping also speeds up the product development cycle, allowing us to test and refine parts before mass production. This custom – design capability gives our electronic products a competitive edge in the market, meeting the diverse needs of consumers.

4. CNC Machining Services: Ensuring Quality and Consistency in Mass Production

In the mass production of electronic products, maintaining quality and consistency is paramount, and CNC machining services play a vital role in this aspect. Once the design is finalized, CNC machines can reproduce components with identical specifications thousands of times. The automated nature of CNC machining reduces human error, ensuring that each part meets the strict quality standards we set.

For example, when manufacturing a large batch of smartphone frames, CNC machines can produce each frame with the same precision and quality. Regular quality checks are integrated into the CNC machining process, using advanced measurement tools to verify dimensions and surface finishes. This consistency in production not only improves the reliability of our electronic products but also streamlines the assembly process, reducing production costs and increasing efficiency.

5. CNC Machining Services: Driving Innovation in Electronic Product Design

As the electronics industry continues to innovate, CNC machining services are at the forefront of driving new design possibilities. Advanced multi – axis CNC machining technologies, combined with emerging materials, allow us to create more complex and integrated components. We can now machine parts with internal cavities, undercuts, and interlocking features that were previously impossible or extremely difficult to produce.

For example, in the development of foldable smartphones, CNC machining has been instrumental in creating the precision – engineered hinge components. These components require intricate geometries and tight tolerances to ensure smooth folding and unfolding while maintaining structural strength. Additionally, the use of sustainable materials in CNC machining, along with the recyclability of the machined parts, aligns with the growing demand for environmentally friendly electronics. Through continuous exploration of CNC machining capabilities, we can drive the development of more innovative, sustainable, and user – centric electronic products that shape the future of the industry.