In the dynamic and consumer – centric realm of household appliances, CNC machining services have emerged as a game – changing force, enabling us to craft products that combine functionality, durability, and aesthetic appeal. These services, with their computer – controlled precision and versatility, allow us to fabricate a wide array of components with exacting specifications, meeting the diverse needs of modern households. From creating robust structural parts to producing intricate decorative elements, CNC machining services play an indispensable role in our pursuit of developing high – quality, innovative household appliances that enhance daily living experiences. They have seamlessly integrated into our manufacturing processes, empowering us to stay competitive in an industry constantly evolving to meet consumers’ expectations.

1. CNC Machining Services: Fabricating Sturdy Structural Components

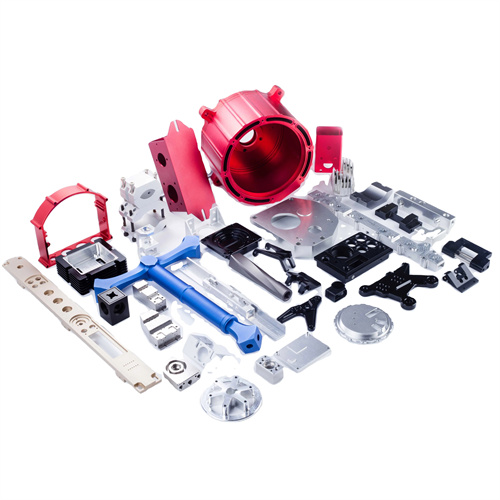

One of the primary applications of CNC machining services in household appliances is the fabrication of sturdy structural components. These components form the backbone of appliances, providing stability and support. We utilize CNC machining to create parts such as frames, brackets, and housings from materials like steel, aluminum, and high – strength plastics. The precision of CNC milling and turning processes ensures that each component is manufactured with exact dimensions, enabling seamless assembly and reliable performance.

For example, in refrigerators, CNC – machined steel frames provide the necessary strength to support heavy shelves, drawers, and the compressor unit. The computer – controlled nature of CNC machining allows for the creation of complex shapes and cutouts, ensuring a perfect fit for internal components and maximizing available storage space. Similarly, in washing machines, CNC – fabricated aluminum brackets are used to secure the drum, absorbing vibrations during operation and reducing noise. The high level of precision in CNC machining guarantees that these structural components can withstand the rigors of daily use, enhancing the overall durability and lifespan of the appliances.

2. CNC Machining Services: Producing Precision – Engineered Functional Parts

CNC machining services are crucial for producing precision – engineered functional parts that are essential for the operation of household appliances. We rely on CNC machining to manufacture components such as gears, shafts, and valves with tight tolerances, ensuring smooth and efficient performance. Using materials like brass, stainless steel, and engineering plastics, we can create parts that are resistant to wear, corrosion, and high temperatures.

In dishwashers, for instance, CNC – machined brass gears are used in the water pump system to ensure consistent water flow and pressure. The precision of CNC machining allows for the creation of gears with accurate tooth profiles, reducing friction and noise during operation. In coffee makers, CNC – fabricated stainless – steel valves control the flow of water and coffee, ensuring precise brewing. These precision – engineered functional parts, crafted through CNC machining, contribute significantly to the reliable and efficient operation of household appliances, enhancing user satisfaction.

3. CNC Machining Services: Creating Aesthetically Pleasing Decorative Elements

Aesthetic appeal is an important aspect of modern household appliances, and CNC machining services enable us to create aesthetically pleasing decorative elements. We can use CNC – controlled laser engraving and cutting to produce intricate patterns, logos, and text on various materials, such as metal, plastic, and glass, adding a touch of elegance and style to our products.

For example, in high – end kitchen appliances like ovens and cooktops, CNC – engraved stainless – steel panels with brand logos and decorative patterns enhance the visual appeal and brand identity. The precision of laser engraving allows for the creation of fine details and gradients, giving the appliances a luxurious look. In addition, CNC – cut plastic handles and knobs with ergonomic designs not only provide a comfortable grip but also contribute to the overall aesthetic of the appliances. These decorative elements, crafted through CNC machining, make our household appliances not only functional but also visually appealing, standing out in the market.

4. CNC Machining Services: Facilitating Customization and Personalization

The flexibility of CNC machining services allows us to offer customization and personalization options for household appliances, meeting the unique preferences of consumers. Whether it’s custom – colored casings, personalized engravings, or specialized features, CNC machining enables us to bring consumers’ ideas to life.

For instance, in the production of small kitchen appliances like toasters and blenders, consumers can choose from a variety of custom – colored housings, which are fabricated using CNC – painted and finished processes. Additionally, we can use CNC machining to create custom – engraved names or messages on appliance surfaces, making them unique and personalized gifts. In built – in appliances, such as range hoods and microwaves, CNC – machined brackets and mounting plates can be customized to fit specific kitchen designs, providing a seamless integration with the overall kitchen layout. This customization and personalization capability not only enhances the consumer experience but also gives our products a competitive edge in the market.

5. CNC Machining Services: Driving Innovation in Appliance Design

As the household appliance industry continues to evolve, CNC machining services are at the forefront of driving innovation in appliance design. Advanced CNC machining technologies, combined with the development of new materials, enable us to explore new design possibilities and create more efficient, intelligent, and sustainable appliances.

For example, CNC machining allows us to create complex internal structures and airflow channels in air conditioners and fans, optimizing their cooling and ventilation performance. The use of multi – axis CNC machining enables the production of parts with intricate 3D geometries, facilitating the integration of multiple functions into a single appliance. Moreover, CNC machining promotes sustainable design by reducing material waste through precise cutting and shaping, and by enabling the use of recyclable materials. Through continuous exploration and application of CNC machining services, we can drive the development of more innovative, user – friendly, and environmentally friendly household appliances that meet the evolving needs of consumers.