In the dynamic and innovation – driven field of LED lighting, CNC milling services have emerged as a pivotal force, enabling us to craft components and products that combine high – performance, precision, and aesthetic appeal. Leveraging the computer – controlled precision and versatility of CNC milling, we can fabricate intricate parts from a wide range of materials, addressing the diverse requirements of modern LED lighting systems. From optimizing heat dissipation to creating customized optical elements, CNC milling services play an indispensable role in our pursuit of developing cutting – edge LED lighting solutions that illuminate spaces efficiently and beautifully. They have seamlessly integrated into our manufacturing processes, empowering us to meet the ever – evolving demands of the market and stay ahead in the competitive landscape.

1. CNC Milling Services: Fabricating High – Efficiency Heat Sinks

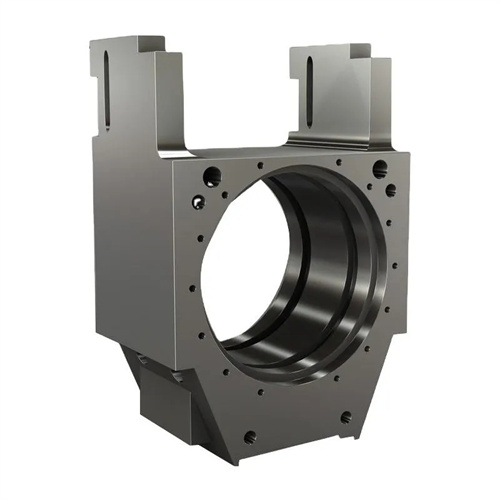

One of the primary applications of CNC milling services in LED lighting is the fabrication of high – efficiency heat sinks. Effective heat dissipation is crucial for maintaining the performance and extending the lifespan of LED components, as excessive heat can lead to reduced brightness and premature failure. We utilize CNC milling to shape heat sink materials, such as aluminum and copper, into intricate structures that maximize the surface area for heat transfer.

For example, in high – power LED floodlights, CNC – milled aluminum heat sinks are designed with densely packed fins. The precision of CNC milling allows for the creation of fins with consistent thickness, precise spacing, and optimized height. This ensures uniform heat distribution and efficient air circulation around the heat sink, effectively dissipating the heat generated by the LEDs. Additionally, CNC milling enables the machining of complex geometries, such as stepped or tapered fins, which further enhance the heat – dissipation performance. These high – efficiency heat sinks, crafted through CNC milling, are essential for ensuring the stable and long – term operation of LED lighting products.

2. CNC Milling Services: Creating Precision Optical Components

Optical components are vital for optimizing the light distribution and performance of LED lighting, and CNC milling services excel in their production. We use CNC milling to fabricate lenses, reflectors, and diffusers from materials like acrylic, polycarbonate, and glass, with a high degree of accuracy and surface finish.

In LED streetlights, CNC – milled reflectors are crucial for directing light precisely onto the road surface. The CNC milling process enables the creation of reflectors with complex curved surfaces and precise angles, ensuring that the light is focused and distributed in the desired pattern. This not only improves the visibility of the road but also reduces light pollution. For LED spotlights, CNC – milled lenses can be customized to achieve specific beam angles, allowing for targeted illumination. The smooth and accurate surfaces produced by CNC milling minimize light scattering, enhancing the overall efficiency and quality of the light output.

3. CNC Milling Services: Producing Customized LED Light Housings

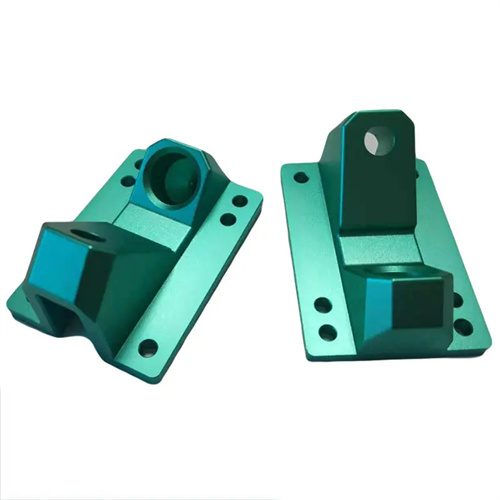

CNC milling services offer the flexibility to produce customized LED light housings that meet the specific design and functional requirements of different projects. Whether it’s for indoor or outdoor applications, we can use CNC milling to create housings from materials such as aluminum alloy, stainless steel, or die – cast zinc.

For architectural LED lighting installations, CNC – milled aluminum housings can be tailored to match the unique aesthetics of the building. The milling process allows for the creation of intricate patterns, cutouts for ventilation, and precise mounting holes. In addition, the surface finish of the housings can be customized, with options such as anodizing, powder coating, or brushing, to enhance the visual appeal and durability. For outdoor LED fixtures, CNC – milled stainless – steel housings provide excellent corrosion resistance, ensuring the long – term performance of the lights in harsh environments. These customized LED light housings not only protect the internal components but also contribute to the overall look and functionality of the lighting system.

4. CNC Milling Services: Ensuring Assembly Precision and Compatibility

In the assembly of LED lighting products, precision and compatibility of components are essential for ensuring reliable performance. CNC milling services play a crucial role in producing parts that fit together seamlessly, reducing the risk of assembly errors and improving the overall quality of the final product.

For example, when manufacturing LED panel lights, CNC – milled aluminum frames and brackets are produced with exacting tolerances. The precise holes and slots in these parts ensure that the LED modules, power supplies, and diffusers can be assembled accurately, without any misalignment or interference. In LED downlights, CNC – milled heat sink bases and trim rings are designed to fit perfectly, ensuring efficient heat transfer and a secure installation. By using CNC – milled components, we can streamline the assembly process, reduce production costs, and enhance the reliability and consistency of our LED lighting products.

5. CNC Milling Services: Driving Innovation in LED Lighting Design

As the LED lighting industry continues to evolve, CNC milling services are at the forefront of driving innovation in design. Advanced CNC milling technologies, combined with the latest material science advancements, enable us to explore new design possibilities and create more compact, efficient, and intelligent LED lighting products.

For instance, multi – axis CNC milling allows for the production of complex, integrated components that combine heat – dissipation, optical, and structural functions. This enables the development of more streamlined and space – saving LED lighting designs. Additionally, the use of new materials, such as high – thermal – conductivity composites and lightweight alloys, in conjunction with CNC milling, opens up new opportunities for improving the performance and reducing the weight of LED lighting products. The ability to quickly prototype using CNC milling also accelerates the product development cycle, allowing us to test and refine new designs more rapidly. Through continuous exploration and application of CNC milling services, we can drive the development of more innovative, sustainable, and user – friendly LED lighting solutions that shape the future of the lighting industry.