In the rapidly evolving and highly competitive landscape of electronic products, CNC milling services have emerged as a cornerstone for achieving unparalleled precision, functionality, and aesthetic appeal. With their computer – controlled accuracy and versatility, these services empower us to fabricate a wide range of components from diverse materials, meeting the exacting demands of modern electronics. From crafting ultra – thin casings for smartphones to producing intricate parts for high – end computing devices, CNC milling services play an indispensable role in our pursuit of developing cutting – edge electronic products that redefine user experiences. They have seamlessly integrated into our manufacturing processes, enabling us to stay ahead in an industry where innovation and quality are paramount.

1. CNC Milling Services: Fabricating Precision Electronic Enclosures

One of the primary applications of CNC milling services in electronic products is the fabrication of precision enclosures. In an era where the design and ergonomics of electronics are highly valued, enclosures serve as both protective barriers and brand – defining elements. We utilize CNC milling to create enclosures from materials such as aluminum alloy, stainless steel, and high – strength plastics, ensuring each piece is manufactured with meticulous attention to detail.

For example, in the production of high – end smartphones, CNC – milled aluminum alloy casings are meticulously crafted to achieve a perfect balance of thinness and strength. The precision of CNC milling allows for the creation of ultra – smooth surfaces, precise cutouts for buttons, ports, and cameras, and seamless integration of antennae. The ability to mill complex geometries enables us to design enclosures with curved edges and ergonomic shapes that fit comfortably in the hand. Additionally, the tight tolerances achieved through CNC milling ensure that internal components fit snugly, reducing the risk of damage from vibrations and impacts. These precision – fabricated enclosures not only protect the delicate internal circuitry but also enhance the overall aesthetic and user experience of the electronic products.

2. CNC Milling Services: Producing High – Precision Internal Components

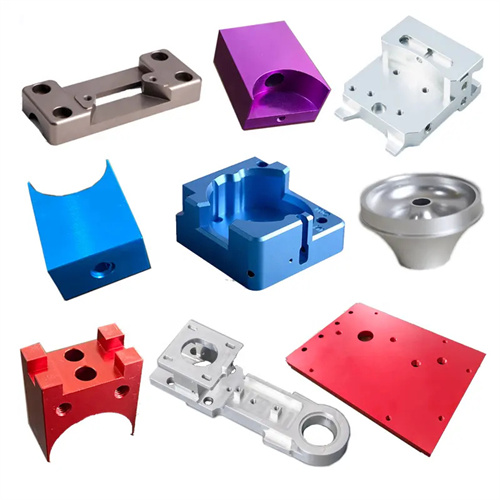

CNC milling services are crucial for producing high – precision internal components that are essential for the functionality of electronic products. From connectors and heat sinks to brackets and structural supports, these components require exacting tolerances to ensure optimal performance. We rely on CNC milling to manufacture parts from materials like copper, brass, and specialized alloys, leveraging the technology’s ability to create intricate shapes and fine details.

In the case of heat sinks for laptops and gaming consoles, CNC – milled aluminum fins are designed with a high degree of precision. The spacing, thickness, and shape of each fin are carefully controlled to maximize the surface area for heat dissipation while maintaining structural integrity. For connectors, CNC milling enables the production of parts with precise pin configurations and contact surfaces, ensuring stable electrical connections. Additionally, CNC – milled brackets and frames provide the necessary support for internal components, ensuring they remain securely in place during operation. These high – precision internal components, crafted through CNC milling, are vital for the reliable and efficient operation of electronic products, enhancing their performance and lifespan.

3. CNC Milling Services: Creating Custom – Designed Electronic Parts

The flexibility of CNC milling services allows us to create custom – designed electronic parts tailored to the unique requirements of specific projects or products. Whether it’s a specialized adapter for a niche device or a custom – shaped component for a limited – edition gadget, CNC milling enables us to bring our designs to life with exceptional accuracy.

For instance, in the development of wearable electronics, custom – designed casings and mounting structures are often required to fit the unique form factors. CNC milling allows us to produce parts with complex 3D shapes that not only meet the functional requirements but also enhance the aesthetic appeal. In the case of custom – made circuit boards, CNC – milled enclosures can be designed to house the boards securely, with precise cutouts for connectors and components. The ability to quickly prototype using CNC milling also speeds up the product development cycle, allowing us to test and refine designs before mass production. This custom – design capability gives our electronic products a competitive edge in the market, meeting the diverse needs of consumers and businesses alike.

4. CNC Milling Services: Enhancing the Aesthetic and Durability of Electronic Products

Aesthetic appeal and durability are key factors that influence consumer perception and satisfaction with electronic products, and CNC milling services contribute significantly to both aspects. We use CNC – controlled processes such as polishing, engraving, and texturing to enhance the visual appeal of electronic components and enclosures.

For example, in consumer electronics like tablets and smartwatches, CNC – milled aluminum surfaces can be polished to a high – gloss finish or textured for a unique look. Laser engraving, often integrated with CNC milling, allows for the creation of intricate logos, patterns, and serial numbers, adding a touch of elegance and personalization. In terms of durability, CNC – milled components can be designed with reinforced edges and corners, as well as with materials that offer superior resistance to wear and corrosion. The precision of CNC milling ensures that these aesthetic and durability enhancements do not compromise the functionality of the products, resulting in electronic devices that are both visually appealing and built to last.

5. CNC Milling Services: Driving Innovation in Electronic Product Design

As the electronics industry continues to push the boundaries of technology, CNC milling services are at the forefront of driving innovation in product design. Advanced multi – axis CNC milling technologies, combined with the latest material science advancements, allow us to create more complex, integrated, and intelligent electronic components.

For example, multi – axis CNC milling enables the production of components with internal cavities, undercuts, and interlocking features that were previously difficult or impossible to manufacture. This allows for more compact and efficient designs, as well as the integration of multiple functions into a single component. The use of new materials, such as carbon fiber composites and high – strength polymers, in conjunction with CNC milling, opens up new possibilities for creating lightweight yet robust electronic products. Additionally, the rapid prototyping capabilities of CNC milling facilitate the exploration of new design concepts, enabling us to quickly test and iterate on ideas. Through continuous exploration and application of CNC milling services, we can drive the development of more innovative, user – centric, and sustainable electronic products that shape the future of the industry.