In the dynamic and consumer – centric world of household appliances, CNC milling services have become a transformative force, enabling us to craft products that combine functionality, durability, and aesthetic charm. With their computer – controlled precision and adaptability to various materials, these services empower us to fabricate components ranging from robust structural parts to intricately designed details. Whether it’s enhancing the performance of kitchen appliances or improving the ergonomics of home electronics, CNC milling services play an indispensable role in our pursuit of developing household appliances that meet the diverse needs of modern families. They have seamlessly integrated into our manufacturing processes, allowing us to stay competitive in an industry constantly evolving to satisfy consumers’ growing expectations.

1. CNC Milling Services: Fabricating Sturdy Structural Components for Appliances

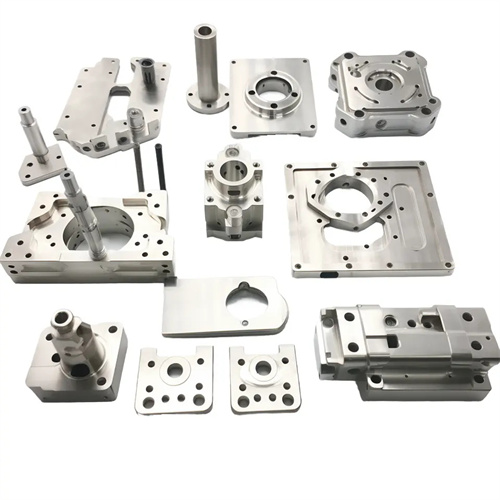

One of the primary applications of CNC milling services in household appliances is the fabrication of sturdy structural components. These components form the foundation of appliances, ensuring stability and reliable operation. We utilize CNC milling to create frames, brackets, and housings from materials such as steel, aluminum, and high – quality plastics, with meticulous attention to precision and durability.

For instance, in refrigerators, CNC – milled steel frames provide the essential support for heavy shelves, drawers, and the compressor unit. The precision of CNC milling allows for the creation of exact cutouts and mounting holes, ensuring that all internal components fit seamlessly. This not only enhances the structural integrity but also reduces vibrations and noise during operation. In washing machines, CNC – fabricated aluminum brackets are used to secure the drum, with precisely milled surfaces ensuring smooth rotation and minimizing wear. The tight tolerances achieved through CNC milling guarantee that these structural components can withstand the rigors of daily use, significantly extending the lifespan of the appliances.

2. CNC Milling Services: Producing Precision – Engineered Functional Parts

CNC milling services are crucial for producing precision – engineered functional parts that are vital for the optimal performance of household appliances. We rely on CNC milling to manufacture components like gears, shafts, valves, and knobs from materials such as brass, stainless steel, and engineering plastics, leveraging the technology’s ability to create complex geometries with high accuracy.

In dishwashers, for example, CNC – milled brass gears are used in the water pump system. The precise tooth profiles and dimensions of these gears, achieved through CNC milling, ensure smooth and consistent water flow, enabling efficient cleaning. In coffee makers, CNC – fabricated stainless – steel valves control the precise flow of water and coffee, contributing to the perfect brewing process. For oven knobs, CNC – milled plastic components can be designed with ergonomic shapes and textures, providing a comfortable grip and precise control over temperature and cooking settings. These precision – engineered parts, crafted through CNC milling, are essential for the reliable and efficient operation of household appliances, enhancing the overall user experience.

3. CNC Milling Services: Creating Custom – Designed Appliance Elements

The flexibility of CNC milling services allows us to create custom – designed elements for household appliances, catering to the unique preferences and requirements of consumers. Whether it’s a specialized handle for a high – end blender or a custom – shaped control panel for a smart oven, CNC milling enables us to bring innovative designs to life with exceptional accuracy.

For luxury kitchen appliances, CNC – milled metal handles with intricate patterns or engraved logos can add a touch of elegance and exclusivity. The precision of CNC milling allows for the creation of fine details and smooth finishes, enhancing the aesthetic appeal while ensuring a comfortable grip. In the case of smart home appliances, custom – designed control panels can be CNC – milled to integrate touch – sensitive surfaces, display windows, and buttons in a seamless and intuitive layout. The ability to quickly prototype using CNC milling also speeds up the product development cycle, allowing us to test and refine designs before mass production, and providing consumers with appliances that are both functional and stylish.

4. CNC Milling Services: Enhancing the Aesthetic Appeal of Home Appliances

Aesthetic appeal is increasingly important in household appliances, and CNC milling services offer a wealth of possibilities for creating visually stunning designs. We use CNC – controlled processes such as polishing, texturing, and engraving to enhance the appearance of appliance components, transforming them into attractive elements that complement modern home decor.

For example, in high – end induction cooktops, CNC – milled stainless – steel surfaces can be polished to a mirror – like finish or textured with unique patterns, adding a luxurious look to the kitchen. In vacuum cleaners, CNC – milled plastic housings can be designed with sleek curves and smooth transitions, combining functionality with an eye – catching appearance. Laser engraving, often integrated with CNC milling, can be used to create brand logos, decorative motifs, or even user – friendly instructions on appliance surfaces, enhancing both the aesthetic and usability of the products. These aesthetic enhancements achieved through CNC milling not only make our household appliances more appealing to consumers but also help to strengthen brand identity.

5. CNC Milling Services: Driving Innovation in Appliance Design and Sustainability

As the household appliance industry moves towards greater innovation and sustainability, CNC milling services are at the forefront of driving these developments. Advanced CNC milling technologies, combined with new material innovations, allow us to create more efficient, intelligent, and eco – friendly appliances.

Multi – axis CNC milling enables the production of complex, integrated components that can combine multiple functions, reducing the number of parts and streamlining manufacturing processes. For example, in energy – efficient air conditioners, CNC – milled components can be designed to optimize airflow and heat exchange, improving performance while reducing energy consumption. Additionally, CNC milling promotes sustainability by enabling the use of recycled materials and minimizing material waste through precise cutting and shaping. The ability to quickly adapt designs using CNC milling also allows us to respond faster to changing consumer demands and technological advancements, driving the development of more innovative and sustainable household appliances that shape the future of the industry.