In the ever – evolving and highly competitive construction industry, CNC milling services have emerged as a game – changing force, enabling us to achieve unparalleled precision, efficiency, and creativity in building projects. Leveraging computer – controlled precision and the ability to work with diverse materials, these services empower us to fabricate a wide range of components, from robust structural elements to intricate architectural details. Whether it’s constructing towering skyscrapers or designing unique residential buildings, CNC milling services play an indispensable role in our pursuit of creating structures that are not only functional and durable but also aesthetically remarkable. They have seamlessly integrated into our construction processes, allowing us to bring our most ambitious architectural visions to life.

1. CNC Milling Services: Fabricating High – Precision Structural Components

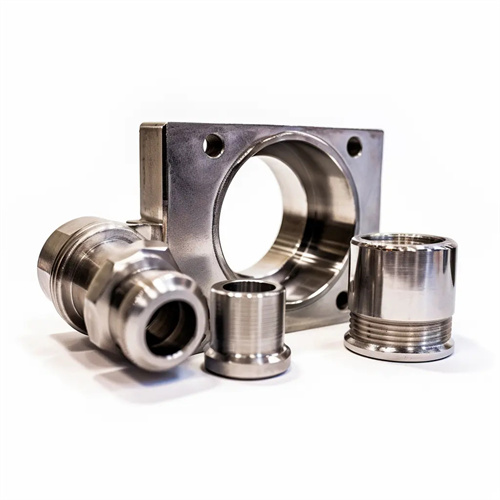

One of the primary applications of CNC milling services in the construction industry is the fabrication of high – precision structural components. In large – scale building projects, the stability and safety of structures rely heavily on precisely manufactured parts. We utilize CNC milling to create beams, columns, and connectors from materials such as steel, aluminum, and engineered composites. The computer – controlled nature of CNC milling ensures that each component is crafted with exact dimensions and angles, guaranteeing a perfect fit during assembly.

For example, in the construction of skyscrapers, CNC – milled steel beams are essential for supporting the immense weight of multiple floors. The milling process allows for the creation of beams with complex cross – sectional shapes and precisely positioned holes for bolts and other connectors. This not only enhances the structural integrity but also reduces the need for on – site modifications, saving time and labor costs. In bridge construction, CNC – fabricated aluminum connectors are used to join different sections, ensuring a strong and reliable connection that can withstand heavy loads and environmental stresses.

2. CNC Milling Services: Creating Intricate Architectural Details

CNC milling services excel at creating intricate architectural details that add character and uniqueness to buildings. Architects often envision elaborate designs for facades, decorative elements, and interior finishes, and CNC milling makes these visions a reality. We can use CNC milling to carve detailed patterns, motifs, and inscriptions into materials like stone, wood, and metal.

In historic building restorations, for instance, CNC milling is used to replicate ornate stone carvings and moldings with remarkable accuracy. The technology can precisely reproduce even the most delicate details, ensuring that the restored structures maintain their original aesthetic. In modern architecture, CNC – milled metal panels with complex geometric patterns are used to create eye – catching facades. These panels can be customized to fit the specific design requirements of each project, allowing for endless possibilities in architectural expression. The ability to create such intricate details with CNC milling elevates the visual appeal of buildings and contributes to the overall architectural identity.

3. CNC Milling Services: Producing Custom – Designed Building Components

The flexibility of CNC milling services allows us to produce custom – designed building components tailored to the unique needs of each construction project. Whether it’s a specialized window frame, a custom – shaped staircase, or a one – of – a – kind door handle, CNC milling enables us to bring our designs to life with exceptional precision.

For example, in sustainable building projects, CNC – milled wooden window frames can be designed to maximize natural light while minimizing heat loss. The precision of CNC milling ensures that the frames fit perfectly into the building envelope, providing an air – tight seal. In luxury residential projects, custom – designed metal railings and staircases are fabricated using CNC techniques, combining strength and elegance. These custom – designed components not only meet the specific requirements of the project but also add a touch of exclusivity and personalization, enhancing the value and appeal of the building.

4. CNC Milling Services: Enhancing Construction Efficiency and Quality Control

In the construction industry, efficiency and quality control are of utmost importance, and CNC milling services significantly contribute to both aspects. The automated and precise nature of CNC milling reduces human error, ensuring that each component is produced to the same high standards. This consistency in quality minimizes the need for rework and repairs, saving time and costs during construction.

Moreover, CNC milling can produce components at a faster rate compared to traditional methods, especially for complex or repetitive parts. For example, in prefabrication projects, CNC – milled components can be manufactured off – site and then quickly assembled on – site, reducing construction time and disruption. Additionally, CNC machines can be integrated with quality control systems, using sensors and measuring devices to verify the dimensions and quality of each component in real – time. This level of precision and control ensures that the final construction meets or exceeds industry standards, enhancing the overall quality and reputation of our projects.

5. CNC Milling Services: Driving Innovation in Sustainable Construction

As sustainability becomes a key focus in the construction industry, CNC milling services are driving innovation in eco – friendly building practices. We can use CNC milling to optimize the use of materials, reducing waste by precisely cutting and shaping components to fit the exact requirements of the project. Additionally, CNC milling enables the use of sustainable materials, such as recycled metals and reclaimed wood, in construction.

For example, in green building projects, CNC – milled recycled aluminum panels are used for facades, combining environmental sustainability with modern design. The precision of CNC milling allows for the creation of panels with complex geometries that can improve energy efficiency by optimizing solar shading and natural ventilation. In addition, CNC – fabricated modular building components made from sustainable materials can be easily disassembled and reused, reducing the environmental impact of construction and demolition. Through continuous exploration and application of CNC milling services in sustainable construction, we can contribute to a more environmentally friendly future for the building industry.