In the vibrant and imaginative realm of the toy industry, CNC milling services have emerged as a game – changing asset, empowering us to craft toys that seamlessly blend creativity, safety, and durability. Leveraging the computer – controlled precision of CNC milling, we can fabricate a diverse range of components from various materials, catering to the unique requirements of different toy designs. Whether it’s creating intricate parts for construction toys or producing custom – designed elements for collectible figures, CNC milling services play an indispensable role in our pursuit of developing toys that inspire children’s imagination and meet the highest standards of quality. These services have become an integral part of our manufacturing processes, enabling us to stay competitive in an industry that thrives on innovation and charm.

1. CNC Milling Services: Fabricating Precise Parts for Construction Toys

One of the primary applications of CNC milling services in the toy industry is the fabrication of precise parts for construction toys. These toys, which encourage children’s spatial awareness and problem – solving skills, rely on accurately made components for a seamless building experience. We utilize CNC milling to create blocks, connectors, and structural elements from materials such as wood, plastic, and metal.

For instance, in wooden building block sets, CNC – milled blocks are cut with meticulous precision. The computer – controlled nature of CNC milling ensures that each block has uniform dimensions, allowing for a perfect fit when stacked. The smooth surfaces and rounded edges, achieved through the milling process, eliminate the risk of splinters, ensuring the safety of young users. In metal construction toys, CNC – fabricated connectors with precisely designed holes and slots enable children to assemble complex structures with ease. The tight tolerances maintained by CNC milling guarantee that each part fits together consistently, providing a reliable and enjoyable building experience for children.

2. CNC Milling Services: Producing Custom – Designed Elements for Collectible Toys

CNC milling services excel at producing custom – designed elements for collectible toys, where uniqueness and detail are highly valued. Whether it’s a limited – edition action figure or a specialized model vehicle, we can use CNC milling to bring our creative visions to life with exceptional accuracy. We work with materials like resin, metal, and high – quality plastics to fabricate parts that meet the exact specifications of each collectible item.

For example, in the production of high – end action figures, CNC – milled heads, hands, and accessories are crafted with intricate detail. The precision of CNC milling allows for the replication of fine facial features, textured clothing, and unique accessories, making each figure a work of art. In model vehicles, CNC – fabricated wheels, grilles, and body panels are designed to match the scale and aesthetic of the original vehicles. The ability to mill complex shapes and tiny details ensures that these custom – designed elements enhance the value and appeal of collectible toys, captivating the hearts of collectors and enthusiasts alike.

3. CNC Milling Services: Creating Safe and Durable Components for Ride – on Toys

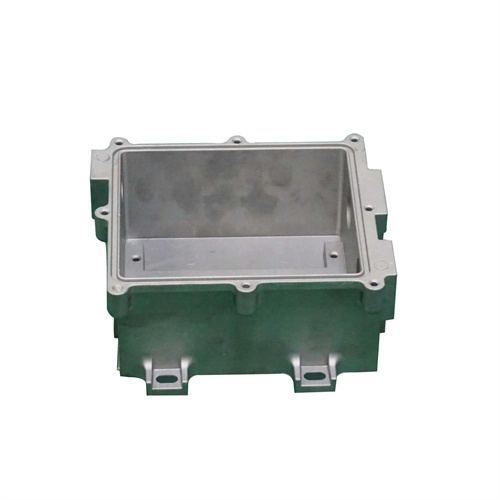

Safety and durability are of utmost importance in ride – on toys, and CNC milling services play a crucial role in creating components that meet these standards. We use CNC milling to produce frames, axles, and other structural parts from sturdy materials such as steel, aluminum, and high – impact plastics. The computer – controlled precision of CNC milling ensures that each component is manufactured to exact specifications, providing a stable and reliable base for children’s play.

For instance, in children’s tricycles, CNC – milled steel frames are designed to withstand the weight of the rider and the rigors of outdoor play. The precise shaping and drilling of holes through CNC milling ensure that the wheels and handlebars can be attached securely, preventing any potential accidents. In pedal cars, CNC – fabricated aluminum axles are crafted with smooth surfaces, ensuring effortless rotation of the wheels. These safe and durable components, created through CNC milling, give parents peace of mind while allowing children to enjoy hours of fun and adventure.

4. CNC Milling Services: Enhancing the Aesthetic Appeal of Toy Packaging

The aesthetic appeal of toy packaging can significantly influence a child’s excitement and a parent’s purchasing decision, and CNC milling services offer valuable solutions for creating eye – catching packaging elements. We use CNC – controlled processes such as milling, engraving, and cutting to produce custom – designed boxes, inserts, and labels from materials like cardboard, paperboard, and plastic.

For example, in the packaging of premium toys, CNC – milled cardboard boxes can be adorned with intricate patterns and embossed logos, creating a sense of luxury and anticipation. The precision of CNC milling allows for the creation of custom – shaped windows and cutouts, showcasing the toy inside while adding an interactive element to the packaging. In addition, CNC – fabricated plastic inserts are designed to hold the toy securely in place, preventing damage during transportation and storage. These aesthetically enhanced packaging elements, crafted through CNC milling, not only protect the toys but also enhance the overall unboxing experience.

5. CNC Milling Services: Driving Innovation in Toy Design and Manufacturing

As the toy industry continues to evolve, CNC milling services are at the forefront of driving innovation in toy design and manufacturing. Advanced multi – axis CNC milling technologies, combined with emerging materials and design software, allow us to explore new possibilities and create toys that are more engaging, educational, and sustainable.

For example, multi – axis CNC milling enables the production of toys with complex internal mechanisms and moving parts, adding an extra layer of interactivity and fun. The ability to quickly prototype using CNC milling also accelerates the product development cycle, allowing us to test and refine new toy designs more efficiently. Moreover, the use of sustainable materials in CNC milling, along with the recyclability of the milled parts, aligns with the growing demand for environmentally friendly toys. Through continuous exploration and application of CNC milling services, we can drive the development of more innovative, child – centric, and eco – conscious toys that shape the future of the industry.