In the competitive and practical world of hardware tools, CNC milling services have emerged as a cornerstone for crafting high – quality, reliable, and innovative products. With their computer – controlled precision and adaptability to various materials, these services empower us to fabricate everything from robust tool bodies to intricate cutting edges. Whether it’s ensuring the durability of hand tools or enhancing the performance of power tools, CNC milling services play an indispensable role in our pursuit of developing hardware tools that meet the diverse needs of professionals and DIY enthusiasts alike. They have seamlessly integrated into our manufacturing processes, enabling us to stay ahead in an industry that demands excellence in every detail.

1. CNC Milling Services: Fabricating Robust Tool Bodies

One of the primary applications of CNC milling services in hardware tools is the fabrication of robust tool bodies. A sturdy tool body forms the foundation for reliable performance, especially when tools are subjected to heavy loads and intense use. We utilize CNC milling to create tool bodies from materials such as steel, aluminum, and high – impact plastics, ensuring each piece is crafted with meticulous attention to strength and ergonomics.

For instance, in the production of hammers, CNC – milled steel heads are shaped with precision to achieve optimal balance and weight distribution. The milling process allows for the creation of smooth surfaces and contoured grips, providing a comfortable hold during extended use. In power tools, such as drills and saws, CNC – fabricated aluminum housings are designed to be lightweight yet durable. The precise cutouts and cavities milled into these housings ensure a perfect fit for internal components, protecting them from dust, debris, and accidental impacts. This level of precision not only enhances the tool’s functionality but also extends its lifespan, making it a reliable companion for various tasks.

2. CNC Milling Services: Producing Precision – Cut Blades and Bits

Precision – cut blades and bits are the workhorses of cutting and drilling tools, and CNC milling services are essential for their production. We rely on CNC milling to manufacture these components from high – quality materials like high – speed steel, carbide, and diamond – coated compounds, ensuring they meet the strictest standards of sharpness and durability.

In circular saws, CNC – milled carbide – tipped blades are crafted with exacting tooth profiles and angles. The computer – controlled nature of CNC milling guarantees that each tooth is uniformly shaped and spaced, enabling smooth and efficient cutting through materials ranging from wood to metal. For drill bits, CNC – fabricated spiral flutes and tip geometries are designed to optimize chip removal and reduce friction during drilling operations. The ability to mill complex shapes and fine details allows us to create blades and bits that deliver consistent performance, even under demanding conditions. These precision – cut components are crucial for achieving clean cuts and accurate holes, making our hardware tools more efficient and reliable.

3. CNC Milling Services: Creating Custom – Designed Hardware Tool Components

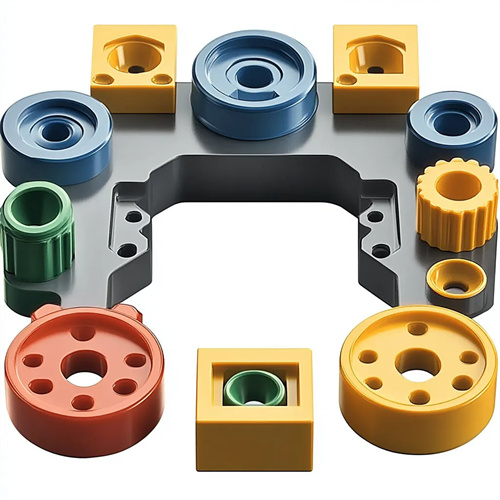

The flexibility of CNC milling services allows us to create custom – designed components for hardware tools, catering to specific user requirements and niche applications. Whether it’s a specialized adapter for a unique task or a custom – shaped handle for improved ergonomics, CNC milling enables us to bring our designs to life with exceptional accuracy.

For example, in industrial settings, where standard tools may not suffice, we can use CNC milling to produce custom – made wrenches with non – standard sizes and shapes. The milling process allows for the creation of intricate features, such as special socket profiles or extended handles, to reach tight spaces or apply extra torque. In the realm of DIY projects, custom – designed handles fabricated through CNC milling can be tailored to fit the user’s hand size and grip style, reducing fatigue and enhancing control. These custom – designed components not only solve specific problems but also add a personalized touch to our hardware tools, making them stand out in the market.

4. CNC Milling Services: Enhancing the Surface Finish and Durability of Tools

The surface finish and durability of hardware tools are critical factors that affect both their performance and appearance, and CNC milling services offer effective solutions for enhancing these aspects. We use CNC – controlled processes such as polishing, grinding, and coating application to improve the surface quality of tools.

For hand tools like pliers and screwdrivers, CNC – milled surfaces can be polished to a smooth, mirror – like finish, reducing friction and making them easier to handle. In addition, CNC – applied coatings, such as anti – corrosion layers and wear – resistant finishes, can significantly extend the lifespan of tools. For power tools operating in harsh environments, CNC – milled components with specialized coatings can withstand exposure to moisture, chemicals, and abrasion. The precision of CNC milling ensures that these surface treatments are evenly applied, providing consistent protection and enhancing the overall aesthetic appeal of the tools.

5. CNC Milling Services: Driving Innovation in Hardware Tool Manufacturing

As the hardware tool industry continues to evolve, CNC milling services are at the forefront of driving innovation in manufacturing. Advanced multi – axis CNC milling technologies, combined with the latest material science advancements, allow us to explore new design possibilities and create more efficient, intelligent, and sustainable tools.

For example, multi – axis CNC milling enables the production of complex, integrated components that combine multiple functions, reducing the need for assembly and improving overall tool performance. The ability to quickly prototype using CNC milling accelerates the product development cycle, allowing us to test and refine new designs more rapidly. Moreover, the use of sustainable materials in CNC milling, along with the recyclability of the milled parts, aligns with the growing demand for environmentally friendly manufacturing practices. Through continuous exploration and application of CNC milling services, we can drive the development of more innovative, high – performance, and eco – conscious hardware tools that shape the future of the industry.