In the vibrant and imaginative world of the toy industry, CNC turning services have emerged as a powerful ally, enabling us to craft toys that combine creativity, safety, and durability with unparalleled precision. Leveraging the computer – controlled rotational machining capabilities, we can produce a diverse range of cylindrical and symmetrical components from various materials, meeting the unique demands of different toy designs. Whether it’s creating essential parts for construction toys or fabricating intricate details for collectible figures, CNC turning services play an indispensable role in our pursuit of developing toys that captivate the hearts and minds of children and collectors alike. These services have seamlessly integrated into our manufacturing processes, allowing us to elevate the quality of our toys and stay competitive in the market.

1. CNC Turning Services: Fabricating Precise Parts for Construction Toys

One of the primary applications of CNC turning services in the toy industry is the fabrication of precise parts for construction toys. These toys, which are designed to stimulate children’s creativity and problem – solving skills, rely on accurately made components for a seamless building experience. We utilize CNC turning to create cylindrical blocks, axles, and connectors from materials such as wood, plastic, and metal.

For instance, in wooden building block sets, CNC – turned cylindrical blocks are crafted with meticulous attention to detail. The precision of CNC turning ensures that each block has a uniform diameter and length, enabling children to stack and connect them effortlessly. The smooth surfaces of these blocks, achieved through the turning process, not only prevent splinters but also enhance the tactile experience for young users. In metal construction toys, CNC – fabricated axles and connectors are essential for joining different parts. The exacting tolerances of CNC turning guarantee a snug fit, allowing children to build stable and complex structures without the frustration of loose or ill – fitting pieces.

2. CNC Turning Services: Producing Custom – Designed Elements for Collectible Toys

Collectible toys often demand unique and detailed components, and CNC turning services excel at producing custom – designed elements that bring these toys to life. We use CNC turning to create parts such as doll limbs, model vehicle axles, and figurine accessories from materials like resin, metal, and high – quality plastics.

For high – end doll collections, CNC – turned resin limbs can be customized to have realistic proportions and smooth surfaces. The turning process allows for the creation of joints with precise diameters, enabling seamless movement and posing of the dolls. In model vehicle collections, CNC – fabricated metal axles are crucial for ensuring smooth wheel rotation. The precision of CNC turning ensures that the axles are straight and have consistent dimensions, enhancing the overall performance and appearance of the models. These custom – designed elements, crafted with the accuracy of CNC turning, add value and authenticity to collectible toys, making them highly sought after by enthusiasts.

3. CNC Turning Services: Creating Safe and Durable Components for Ride – on Toys

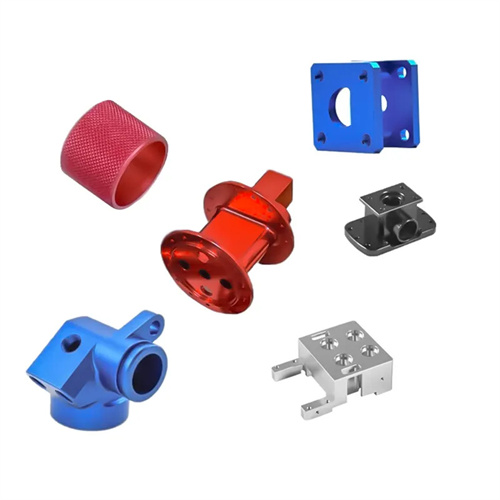

Safety and durability are of utmost importance in ride – on toys, and CNC turning services play a vital role in creating components that meet these standards. We rely on CNC turning to produce parts such as axles, steering columns, and wheel hubs from sturdy materials like steel, aluminum, and high – impact plastics.

For children’s tricycles, CNC – turned steel axles are designed to support the weight of the rider and withstand the rigors of outdoor play. The precision of CNC turning ensures that the axles have a smooth surface and exact dimensions, reducing friction and wear. This not only extends the lifespan of the tricycle but also provides a stable and safe riding experience for children. In pedal cars, CNC – fabricated aluminum wheel hubs are lightweight yet durable. The tight tolerances achieved through CNC turning ensure that the wheels fit securely, preventing any potential accidents caused by loose or wobbly wheels.

4. CNC Turning Services: Enhancing the Aesthetic Appeal of Toy Packaging Components

The aesthetic appeal of toy packaging can significantly influence a child’s excitement and a parent’s purchasing decision, and CNC turning services can be used to create eye – catching packaging components. We use CNC turning to produce parts such as cylindrical packaging tubes, decorative caps, and display stands from materials like cardboard, plastic, and metal.

For example, in the packaging of premium toys, CNC – turned cardboard tubes with smooth surfaces and precise diameters can be used to hold and protect the toys. These tubes can be customized with printed designs or embossed patterns, adding an element of intrigue and luxury. CNC – fabricated plastic caps with unique shapes and textures can be used to seal the tubes, providing a secure and visually appealing closure. In toy display stands, CNC – turned metal rods with polished finishes can be used to showcase the toys in a store, attracting the attention of potential buyers and enhancing the overall presentation of the products.

5. CNC Turning Services: Driving Innovation in Toy Design and Manufacturing

As the toy industry continues to evolve, CNC turning services are at the forefront of driving innovation in design and manufacturing. Advanced CNC turning technologies, combined with emerging materials and digital design tools, allow us to explore new possibilities and create more engaging, educational, and sustainable toys.

For example, multi – axis CNC turning machines enable the production of complex, integrated components with multiple features in a single setup, reducing production time and costs. The use of new materials, such as biodegradable plastics and recycled metals, in conjunction with CNC turning, promotes environmentally friendly toy manufacturing. Additionally, the ability to quickly prototype using CNC turning accelerates the product development cycle, allowing us to test and refine new toy designs more efficiently. Through continuous exploration and application of CNC turning services, we can drive the development of more innovative, child – centric toys that will shape the future of the industry.