In the dynamic and ever – evolving packaging industry, custom precision machining parts have emerged as a game – changing element, enabling us to create packaging solutions that combine functionality, aesthetics, and efficiency. With the ability to fabricate components tailored to specific requirements, these parts empower us to meet the diverse needs of different products and markets. Whether it’s manufacturing intricate molds for plastic packaging or producing custom – designed closures for premium products, custom precision machining parts play an indispensable role in our pursuit of developing innovative and high – quality packaging. They have seamlessly integrated into our manufacturing processes, allowing us to stay competitive in an industry where precision and customization are highly valued.

1. Custom Precision Machining Parts: Fabricating High – Precision Packaging Molds

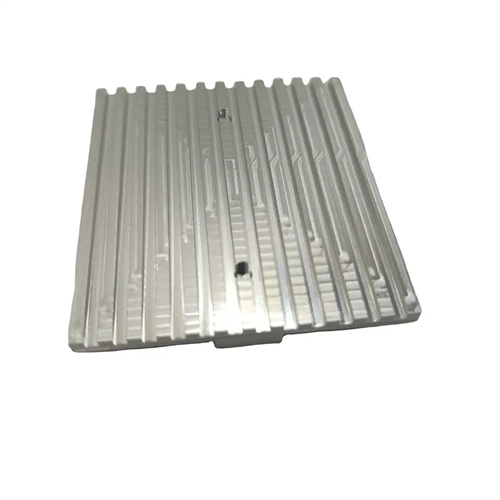

One of the primary applications of custom precision machining parts in the packaging industry is the fabrication of high – precision packaging molds. Molds are the foundation for mass – producing consistent and high – quality packaging products, and precision is crucial for their performance. We utilize custom precision machining to create mold cores, cavities, and inserts from materials such as steel, aluminum, and copper alloys, ensuring each part meets the exact specifications of the packaging design.

For example, in the production of plastic bottle molds, custom – machined steel cores are essential for forming the interior shape of the bottles. The precision of machining allows for the creation of cores with exact dimensions, smooth surfaces, and precise details, resulting in bottles with uniform wall thicknesses, accurate neck profiles, and consistent thread pitches. This level of precision not only improves the quality of the molded bottles but also enhances the efficiency of the production process by reducing material waste and minimizing the need for post – processing adjustments. In injection molding for food packaging trays, custom – fabricated aluminum inserts can be designed with specific patterns or textures to enhance the visual appeal of the trays while also improving their structural integrity.

2. Custom Precision Machining Parts: Producing Custom – Designed Packaging Closures

Custom – designed packaging closures are key to enhancing the functionality, security, and aesthetic appeal of packaged products, and custom precision machining parts enable us to create a wide variety of closures with exceptional accuracy. We use custom precision machining to manufacture caps, lids, stoppers, and closures from materials like plastic, metal, and rubber, tailored to the specific requirements of different packaging applications.

In the cosmetics industry, custom – machined plastic caps with unique shapes, intricate designs, and precise threading can be produced to fit perfectly on bottles and jars, providing a secure seal to protect the contents while also adding a touch of luxury. The ability to customize the surface finish, such as applying a glossy or matte coating, further enhances the visual appeal of the closures. In the beverage industry, custom – fabricated metal caps with embossed logos or patterns not only serve as a branding element but also ensure a reliable seal to maintain the freshness of the products. These custom – designed closures, crafted through precision machining, not only meet the functional needs but also contribute to the overall brand image of the packaged products.

3. Custom Precision Machining Parts: Creating Packaging Support and Display Components

Packaging support and display components play a vital role in protecting products during transportation and showcasing them attractively to consumers, and custom precision machining parts are invaluable in their production. We rely on custom precision machining to fabricate components such as display stands, trays, holders, and partitions from materials like acrylic, metal, and wood, customized to fit the specific dimensions and requirements of the packaged items.

For retail packaging displays, custom – machined acrylic display stands can be designed with precise cutouts and slots to hold products securely in place while also providing an eye – catching presentation. The clarity and transparency of acrylic, combined with the precision of machining, create a modern and elegant look that effectively showcases the products. In the packaging of fragile items, such as electronics or glassware, custom – fabricated metal or plastic holders with precisely contoured shapes can be used to provide shock – absorbing support and prevent damage during handling and shipping. These custom – designed support and display components, produced through precision machining, enhance the functionality and visual appeal of the packaging, ultimately influencing consumer purchasing decisions.

4. Custom Precision Machining Parts: Enhancing the Durability and Aesthetics of Packaging Parts

Durability and aesthetics are two critical aspects of packaging parts, and custom precision machining parts contribute significantly to both. We use various machining processes, such as polishing, anodizing, and coating, to enhance the surface finish and appearance of packaging parts while also improving their resistance to wear, corrosion, and environmental factors.

For metal packaging parts, custom precision machining followed by polishing can create a smooth, mirror – like surface that adds a luxurious feel to the packaging. Anodizing, a common treatment for aluminum parts, not only enhances the aesthetic appeal with a variety of colors but also provides excellent corrosion resistance, ensuring the longevity of the packaging. In the case of plastic parts, custom – applied coatings can be used to improve scratch resistance, UV protection, and chemical resistance. Additionally, precision machining allows for the creation of complex geometries and textures on packaging parts, adding a unique and distinctive look that sets the products apart on the shelves.

5. Custom Precision Machining Parts: Driving Innovation in Packaging Design and Manufacturing

As the packaging industry continues to evolve, custom precision machining parts are at the forefront of driving innovation in design and manufacturing. Advanced machining technologies, combined with the latest material science advancements and digital design tools, allow us to explore new possibilities and create more sustainable, intelligent, and user – friendly packaging solutions.

For example, multi – axis precision machining enables the production of complex, integrated packaging components with multiple features in a single setup, reducing production time and costs. The use of new materials, such as biodegradable plastics and recycled metals, in conjunction with custom precision machining, promotes sustainable packaging practices. Moreover, the ability to quickly prototype custom – designed parts using rapid prototyping techniques, which are closely related to precision machining, accelerates the product development cycle. This allows us to test and refine new packaging designs more efficiently, bringing innovative products to market faster and meeting the changing demands of consumers and the industry. Through continuous exploration and application of custom precision machining parts, we can drive the development of more cutting – edge packaging solutions that will shape the future of the packaging industry.