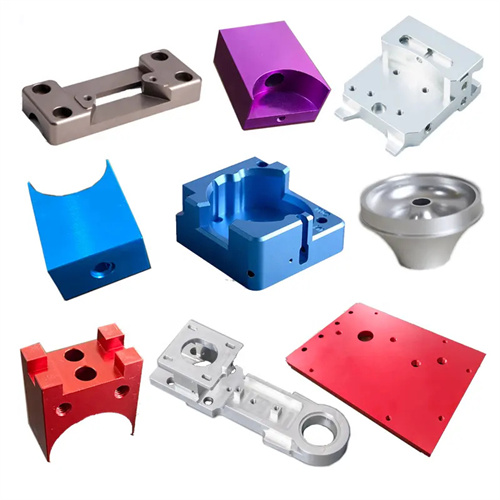

In the ever – evolving and highly demanding construction industry, custom precision machining parts have emerged as an indispensable asset, enabling us to build structures that are not only sturdy and reliable but also showcase innovative designs. With the ability to fabricate components tailored to the specific requirements of each construction project, these parts empower us to overcome complex engineering challenges and meet the stringent standards of modern architecture. Whether it’s for the structural elements of skyscrapers or the decorative details of historic buildings, custom precision machining parts play a pivotal role in our pursuit of constructing high – quality, long – lasting buildings. They have seamlessly integrated into our construction processes, allowing us to bring our architectural visions to life with precision and excellence.

1. Custom Precision Machining Parts: Fabricating Structural Components for High – Rise Buildings

One of the primary applications of custom precision machining parts in the construction industry is the fabrication of structural components for high – rise buildings. These components need to withstand immense loads and environmental stresses, requiring utmost precision in their manufacturing. We utilize custom precision machining to create columns, beams, and joints from materials such as steel, aluminum, and composite alloys, ensuring that each part meets the exact specifications of the building’s structural design.

For instance, in skyscrapers, custom – machined steel columns are crucial for supporting the weight of multiple floors. The precision of machining allows for the creation of columns with consistent cross – sectional dimensions and smooth surfaces, ensuring uniform load distribution. By custom – fabricating joints with precise angles and hole patterns, we can ensure a secure connection between different structural elements, enhancing the overall stability of the building. The ability to customize the shape and size of these components through precision machining enables us to optimize the structural performance of high – rise buildings, making them more resilient to earthquakes, wind forces, and other external factors.

2. Custom Precision Machining Parts: Producing Architectural Details and Ornaments

Custom precision machining parts are highly valued for producing intricate architectural details and ornaments that add character and aesthetic appeal to buildings. Architects often envision elaborate designs for facades, railings, and decorative elements, and custom precision machining allows us to bring these creative concepts to reality. We use custom precision machining to shape materials like metal, wood, and stone into beautiful and detailed architectural features.

In historic building restorations, for example, custom – machined metal balusters and finials can be crafted to replicate the original designs with remarkable accuracy. The precision of machining ensures that every curve, pattern, and detail is faithfully reproduced, helping to preserve the historical integrity of the building. In modern architecture, custom – fabricated stainless – steel or aluminum decorative panels with unique geometric patterns can be used to enhance the visual appeal of building facades. These custom – designed architectural details, produced through precision machining, not only elevate the aesthetic value of buildings but also showcase the craftsmanship and innovation in construction.

3. Custom Precision Machining Parts: Creating Custom – Designed Building Fixtures

The flexibility of custom precision machining parts allows us to create custom – designed building fixtures tailored to the specific needs of different construction projects. Whether it’s a specialized handrail for a staircase, a unique door handle for a luxury residence, or custom – shaped window frames, these parts can be fabricated to meet exact requirements. We use custom precision machining to produce fixtures from materials such as brass, bronze, and high – strength plastics.

For luxury hotels, custom – machined brass door handles with intricate engravings can be designed to reflect the hotel’s opulent style and brand identity. The precision of machining ensures that the handles have a comfortable grip and a perfect fit, providing both functionality and aesthetic appeal. In public buildings, custom – fabricated aluminum handrails with specific angles and lengths can be created to meet safety standards while also complementing the overall architectural design. These custom – designed building fixtures, made possible by precision machining, add a personalized touch to buildings and enhance the user experience.

4. Custom Precision Machining Parts: Enhancing the Quality and Durability of Construction Hardware

Construction hardware, such as bolts, nuts, and hinges, plays a vital role in the assembly and functionality of buildings, and custom precision machining parts can significantly enhance their quality and durability. We use custom precision machining to produce hardware components from high – quality materials like stainless steel and alloy steel, ensuring that they meet strict quality standards.

For large – scale construction projects, custom – machined high – strength bolts and nuts are essential for securely fastening structural components together. The precision of machining ensures that the threads are accurate and consistent, providing a strong and reliable connection. In doors and windows, custom – fabricated hinges with precisely machined pins and barrels can ensure smooth operation and long – term durability. By using custom precision machining parts for construction hardware, we can reduce the risk of component failure, improve the overall quality of the building, and extend its service life.

5. Custom Precision Machining Parts: Driving Innovation in Sustainable Construction

As sustainability becomes a key focus in the construction industry, custom precision machining parts are driving innovation in eco – friendly building practices. We can use custom precision machining to optimize the use of materials, reducing waste by precisely cutting and shaping components to fit the exact requirements of the project. Additionally, custom precision machining enables the use of sustainable materials, such as recycled metals and reclaimed wood, in construction.

For green building projects, custom – machined components made from recycled aluminum can be used for structural supports or decorative elements, combining environmental sustainability with modern design. The precision of machining allows for the creation of components with complex geometries that can improve energy efficiency, such as custom – designed window frames with enhanced insulation properties. In addition, custom – fabricated modular building components made from sustainable materials can be easily disassembled and reused, reducing the environmental impact of construction and demolition. Through continuous exploration and application of custom precision machining parts in sustainable construction, we can contribute to a more environmentally friendly future for the building industry.