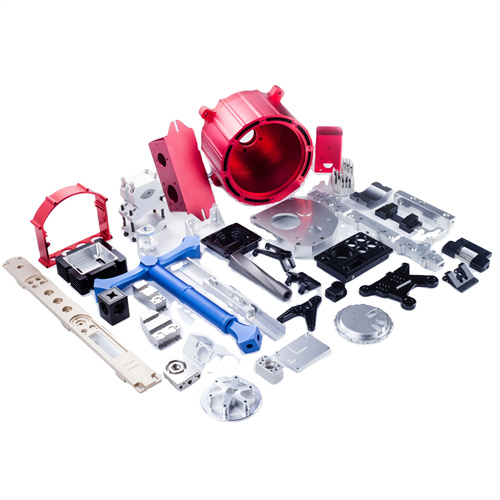

In the highly technical and rapidly evolving field of electrical products, Metal Steel CNC Machining has emerged as an indispensable technology, enabling us to manufacture components that combine exceptional precision, reliability, and durability. Leveraging the computer – controlled accuracy of machining steel, we can produce a wide variety of parts tailored to the specific requirements of different electrical systems. Whether it’s for the robust structural elements of power – intensive equipment or the precisely engineered components of delicate electronics, Metal Steel CNC Machining plays a pivotal role in our pursuit of developing high – quality electrical products. It has seamlessly integrated into our manufacturing processes, allowing us to meet the stringent demands of the industry while driving innovation in electrical product design.

1. Metal Steel CNC Machining: Fabricating High – Strength Electrical Enclosure Frames

One of the primary applications of Metal Steel CNC Machining in electrical products is the fabrication of high – strength electrical enclosure frames. These frames provide essential protection for internal electrical components, shielding them from environmental factors and ensuring user safety. We utilize Metal Steel CNC Machining to create enclosure frames from sturdy steel alloys, customizing their designs to fit the specific dimensions and requirements of each electrical product.

For industrial control panels, Metal Steel CNC Machined steel frames are crucial for withstanding harsh operating conditions. The precision of machining allows for the creation of frames with exact hole patterns, slots, and cutouts, ensuring a perfect fit for circuit breakers, switches, and other electrical devices. By precisely controlling the thickness and shape of the steel during the CNC machining process, we can optimize the strength – to – weight ratio of the frames, making them both robust and lightweight. In addition, the smooth surfaces and consistent dimensions achieved through CNC machining enhance the overall aesthetic appeal of the enclosures, while also facilitating easy assembly and maintenance.

2. Metal Steel CNC Machining: Producing Precision Electrical Connectors

Precision electrical connectors are vital for establishing reliable electrical connections within electrical systems, and Metal Steel CNC Machining plays a significant role in their production. We rely on Metal Steel CNC Machining to manufacture connectors from high – conductivity steel materials, ensuring that each part meets the strictest standards of electrical performance and durability.

For printed circuit board (PCB) assemblies, Metal Steel CNC Machined steel connectors are designed with meticulous precision. The machining process enables the creation of connectors with precise pin diameters, lengths, and pitches, ensuring a secure and stable connection when inserted into the PCB. The tight tolerances achieved through CNC machining minimize electrical resistance and signal loss, enabling efficient power transmission and data transfer. In high – voltage electrical systems, custom – fabricated steel connectors with specialized insulation features can be produced to withstand high electrical loads and prevent electrical leakage. These precision – made connectors, crafted through Metal Steel CNC Machining, are essential for maintaining the integrity and reliability of electrical circuits.

3. Metal Steel CNC Machining: Creating Rotating Components for Electrical Machinery

Electrical machinery, such as motors and generators, relies on precisely manufactured rotating components to function efficiently, and Metal Steel CNC Machining is key to their production. We use Metal Steel CNC Machining to fabricate shafts, rotors, and other rotating parts from high – strength steel alloys, ensuring that each component is optimized for performance and durability.

In electric motors, Metal Steel CNC Machined steel shafts are the backbone of the rotating assembly. The precision of machining ensures that the shafts have consistent diameters, smooth surfaces, and accurately positioned keyways and threads. This precision minimizes vibrations and noise during operation, while also reducing wear and tear on the bearings. For the rotors of generators, custom – fabricated steel components with precisely designed slots and windings can be produced to maximize power generation efficiency. The ability to control the machining process with high accuracy allows us to create rotating components with complex geometries and tight tolerances, enabling the electrical machinery to operate at peak performance.

4. Metal Steel CNC Machining: Enhancing Heat – Dissipation Components for Electrical Products

Effective heat dissipation is crucial for the performance and lifespan of electrical products, especially those operating under high loads, and Metal Steel CNC Machining can be used to enhance heat – dissipation components. We utilize Metal Steel CNC Machining to fabricate heat sinks and heat – conducting elements from steel materials with good thermal conductivity, customizing their designs to meet the specific heat – dissipation requirements of different electrical devices.

For power – intensive electrical equipment, such as power supplies and high – performance processors, Metal Steel CNC Machined steel heat sinks can be designed with complex fin geometries. The precision of machining allows for the creation of fins with consistent thicknesses, uniform spacing, and precise shapes, maximizing the surface area for heat transfer. By precisely shaping the steel heat sinks through CNC machining, we can optimize the airflow around them, ensuring efficient heat dissipation and preventing overheating. In addition, custom – fabricated steel heat pipes with precisely engineered internal structures can be used to transfer heat away from critical components quickly, further enhancing the thermal management of electrical products.

5. Metal Steel CNC Machining: Driving Innovation in Electrical Product Design

As the electrical product industry continues to evolve, Metal Steel CNC Machining is at the forefront of driving innovation in design and manufacturing. Advanced CNC machining technologies, combined with emerging materials and digital design tools, allow us to explore new possibilities and create more compact, efficient, and intelligent electrical products.

For example, multi – axis Metal Steel CNC Machining enables the production of complex, integrated components with multiple features in a single setup, reducing production time and costs. This technology allows us to create electrical parts with intricate internal structures and external shapes that were previously difficult or impossible to achieve, opening up new design opportunities. The use of new steel alloys with improved properties, in conjunction with Metal Steel CNC Machining, also promotes the development of lighter, stronger, and more energy – efficient electrical products. Additionally, the ability to quickly prototype custom – designed parts using Metal Steel CNC Machining accelerates the product development cycle, enabling us to test and refine new designs more rapidly and bring innovative electrical products to market faster. Through continuous exploration and application of Metal Steel CNC Machining, we can drive the future development of the electrical product industry towards greater innovation and excellence.