In the ever – advancing and complex construction industry, Metal Steel CNC Machining has emerged as a transformative force, empowering us to construct structures that seamlessly blend strength, precision, and aesthetic appeal. By leveraging the computer – controlled precision of machining steel, we can fabricate a diverse range of components tailored to the unique requirements of each construction project. Whether it’s for the towering skyscrapers in bustling cities or the intricate details of historical restorations, Metal Steel CNC Machining plays an indispensable role in our pursuit of building high – quality, innovative structures. It has seamlessly integrated into our construction processes, allowing us to overcome engineering challenges and bring our architectural visions to life with unparalleled accuracy.

1. Metal Steel CNC Machining: Fabricating Structural Steel Components for High – Rise Buildings

One of the primary applications of Metal Steel CNC Machining in the construction industry is the fabrication of structural steel components for high – rise buildings. These components serve as the backbone of tall structures, bearing immense loads and ensuring structural stability. We utilize Metal Steel CNC Machining to create columns, beams, and trusses from high – strength steel alloys, customizing their designs to meet the exact specifications of each building’s structural engineering requirements.

For skyscrapers, Metal Steel CNC Machined steel columns are crucial for supporting the weight of multiple floors and resisting lateral forces such as wind and earthquakes. The precision of machining allows for the creation of columns with consistent cross – sectional dimensions and smooth surfaces, ensuring uniform load distribution. By precisely controlling the cutting and shaping of steel through CNC technology, we can fabricate columns with accurate hole patterns for bolt connections, enabling seamless integration with other structural elements. In addition, custom – designed steel beams produced through CNC machining can be tailored to span large distances, providing robust support for floor slabs and roof structures. The high accuracy of Metal Steel CNC Machining ensures that these structural components fit together perfectly, enhancing the overall stability and safety of high – rise buildings.

2. Metal Steel CNC Machining: Producing Architectural Steel Details and Ornaments

Metal Steel CNC Machining is highly valued for producing intricate architectural steel details and ornaments that add character and visual appeal to buildings. Architects often envision elaborate designs for facades, railings, and decorative elements, and CNC machining allows us to bring these creative concepts to life with remarkable precision. We use Metal Steel CNC Machining to shape steel into detailed architectural features, whether it’s for modern buildings or historical restorations.

In historical building restorations, custom – machined steel balusters and finials can be crafted to replicate the original designs with astonishing accuracy. The precision of CNC machining ensures that every curve, pattern, and detail is faithfully reproduced, helping to preserve the historical integrity of the structure. In modern architecture, Metal Steel CNC Machined steel decorative panels with unique geometric patterns or artistic motifs can be used to create striking facades. These panels can be designed with precise cutouts and textures, allowing natural light to filter through and creating dynamic visual effects. The ability to customize the design and dimensions of these architectural steel details through CNC machining enables us to create buildings that are not only functional but also works of art.

3. Metal Steel CNC Machining: Creating Custom – Designed Building Hardware

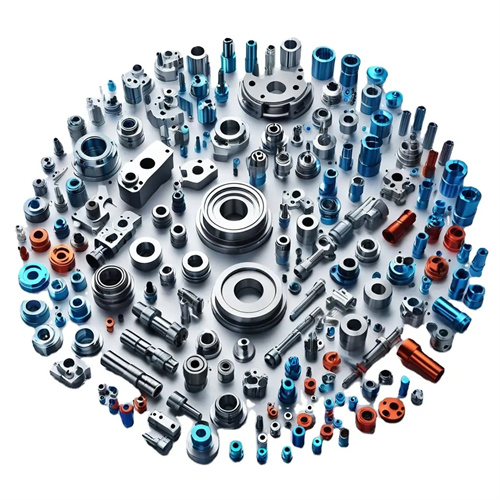

The functionality and durability of building hardware are essential for the smooth operation of buildings, and Metal Steel CNC Machining enables us to create custom – designed hardware components tailored to specific construction needs. We rely on Metal Steel CNC Machining to produce hardware such as door hinges, window locks, and handrail fittings from high – quality steel materials, ensuring that each part meets the highest standards of performance and longevity.

For commercial buildings with heavy – use doors, custom – machined steel door hinges can be designed to withstand frequent opening and closing. The precision of machining allows for the creation of hinges with accurate pin diameters and smooth – operating barrels, ensuring quiet and reliable performance. In residential buildings, custom – fabricated steel window locks with precise geometries can provide enhanced security. The tight tolerances achieved through CNC machining ensure a secure fit, preventing windows from being forced open. Additionally, custom – designed steel handrail fittings produced through Metal Steel CNC Machining can be tailored to match the architectural style of the building while providing sturdy support. These custom – made building hardware components, crafted with precision, contribute to the overall functionality and safety of buildings.

4. Metal Steel CNC Machining: Enhancing the Durability and Corrosion Resistance of Construction Steel Parts

In the construction industry, steel parts are often exposed to various environmental factors, and enhancing their durability and corrosion resistance is crucial. Metal Steel CNC Machining, combined with appropriate surface treatment processes, allows us to improve the performance and lifespan of steel components. We use CNC machining to create steel parts with precise geometries, and then apply treatments such as galvanizing, painting, or powder coating to protect them from corrosion.

For outdoor steel structures like bridges and balconies, Metal Steel CNC Machined steel components can be galvanized after machining. The precision of CNC machining ensures that the parts have smooth surfaces, which allows the galvanized coating to adhere evenly, providing excellent corrosion protection. In coastal areas where buildings are exposed to saltwater and high humidity, custom – fabricated steel parts for facades can be painted with specialized coatings through a process that is facilitated by the accurate dimensions achieved via CNC machining. These surface treatments, enabled by the precision of Metal Steel CNC Machining, not only extend the lifespan of steel construction parts but also reduce maintenance costs over time.

5. Metal Steel CNC Machining: Driving Innovation in Construction Design and Manufacturing

As the construction industry continues to embrace new technologies, Metal Steel CNC Machining is at the forefront of driving innovation in design and manufacturing. Advanced CNC machining techniques, combined with digital design tools and emerging materials, allow us to explore new possibilities and create more sustainable, efficient, and intelligent building solutions.

For example, multi – axis Metal Steel CNC Machining enables the production of complex, integrated steel components with multiple features in a single setup, reducing production time and costs. This technology allows us to create components with intricate internal structures and unique external shapes that were previously difficult or impossible to achieve, opening up new design opportunities for architects and engineers. The use of new high – strength, lightweight steel alloys, in conjunction with Metal Steel CNC Machining, promotes the development of more energy – efficient buildings. Additionally, the ability to quickly prototype custom – designed steel parts using CNC machining accelerates the construction project development cycle. This allows us to test and refine designs more rapidly, bringing innovative construction projects to fruition faster and shaping the future of the construction industry.