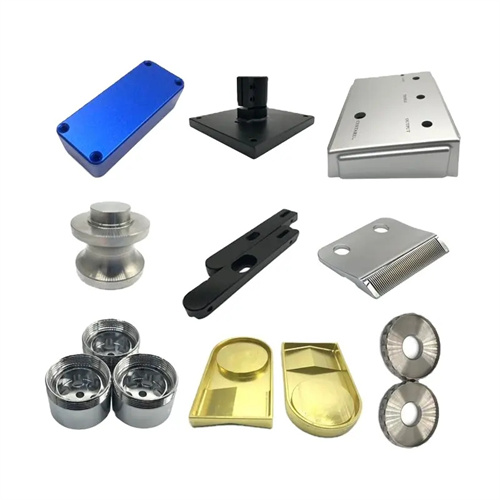

Precision-Crafted Engine Parts with Automotive CNC Machining Services

We recognize that the performance of an automobile heavily depends on the precision of its engine parts, and our Automotive CNC Machining Services are tailored to meet this critical need. Engine components such as cylinder heads, crankshafts, and camshafts demand the highest level of accuracy to ensure optimal combustion and power delivery. With our state-of-the-art CNC machines, we can machine these parts with tight tolerances, ensuring a perfect fit and smooth operation. For instance, when manufacturing cylinder heads, our CNC machining services can precisely create the complex combustion chambers, valve seats, and coolant passages. The advanced multi-axis capabilities of our machines allow us to achieve intricate geometries that enhance engine efficiency and reduce emissions. By using high-quality materials and advanced machining techniques, we produce engine parts that not only meet but often exceed industry standards, contributing to the reliability and performance of modern automotive engines.

Robust and Reliable Brackets via Automotive CNC Machining Services

Brackets play a crucial role in the automotive assembly, providing support and stability to various components. Our Automotive CNC Machining Services enable us to produce robust and reliable brackets that can withstand the rigors of daily driving and harsh road conditions. We start by carefully selecting materials, such as aluminum alloys or high-strength steels, based on the specific requirements of the bracket’s application. Using CNC machining, we can precisely shape the brackets to fit seamlessly with other parts of the vehicle. For example, engine mounts and suspension brackets need to be strong enough to hold heavy components in place while also absorbing vibrations. Our CNC machining processes ensure consistent quality and dimensional accuracy, reducing the risk of failure due to manufacturing defects. Moreover, the ability to produce brackets in a variety of shapes and sizes allows us to meet the diverse needs of different automotive models and aftermarket customization requirements.

Customization at Its Best with Automotive CNC Machining Services

In the automotive industry, the demand for custom components is on the rise, and our Automotive CNC Machining Services are at the forefront of meeting this trend. Whether it’s for high-performance racing cars or personalized street vehicles, we can create custom components that are tailored to our clients’ specific needs. Our team of skilled engineers and designers work closely with customers to understand their vision and translate it into functional and aesthetically pleasing parts. For example, custom intake manifolds, exhaust systems, and body panels can be designed and manufactured using our CNC machining services. The flexibility of CNC technology allows us to make quick design changes and produce small batches of components efficiently. This not only gives car enthusiasts the freedom to express their individuality but also enables automotive manufacturers to develop unique prototypes and limited-edition models, setting them apart in a competitive market.

Efficiency-Driven Production with Automotive CNC Machining Services

We understand that time is of the essence in the automotive industry, and our Automotive CNC Machining Services are designed to optimize production efficiency. The automated nature of CNC machines reduces the need for manual intervention, minimizing the chances of human error and increasing the speed of production. With the ability to program and execute complex machining operations, we can produce multiple engine parts, brackets, or custom components in a single setup, significantly reducing production time. For large-scale automotive manufacturing projects, this efficiency translates into cost savings and faster turnaround times. Additionally, our CNC machining services can be integrated with other manufacturing processes, such as casting and forging, to create hybrid components that combine the best of different production methods. This streamlined approach to production allows us to meet the high-volume demands of the automotive industry while maintaining the highest quality standards.

Quality Assurance in Automotive CNC Machining Services

Quality is non-negotiable in our Automotive CNC Machining Services. We implement a rigorous quality assurance process at every stage of production to ensure that our engine parts, brackets, and custom components meet the strictest automotive industry standards. Our quality control team uses advanced inspection tools, such as coordinate measuring machines (CMMs) and optical scanners, to verify the dimensional accuracy and surface finish of each part. We also conduct material testing to ensure that the selected materials have the required mechanical properties. In addition, we maintain detailed records of the machining process, from programming to tooling, to ensure traceability and consistency. By adhering to these quality assurance practices, we can provide our customers with reliable and durable automotive components that contribute to the overall safety and performance of their vehicles.

Future Prospects of Automotive CNC Machining Services

As we look to the future, we are excited about the potential of our Automotive CNC Machining Services. With the rapid development of electric and autonomous vehicles, the demand for innovative and lightweight components is increasing. Our CNC machining technology will play a crucial role in producing advanced battery enclosures, electric motor parts, and sensor brackets that are essential for these new automotive technologies. Moreover, the integration of artificial intelligence and machine learning into CNC machining will further enhance precision, efficiency, and flexibility. We anticipate that our Automotive CNC Machining Services will continue to evolve, enabling us to produce more complex and high-performance components that meet the ever-changing needs of the automotive industry. By staying ahead of technological advancements and continuously improving our services, we are confident that we can remain a leading provider of automotive CNC machining solutions.