Unveiling the Versatility of Aluminum in CNC Machining Services

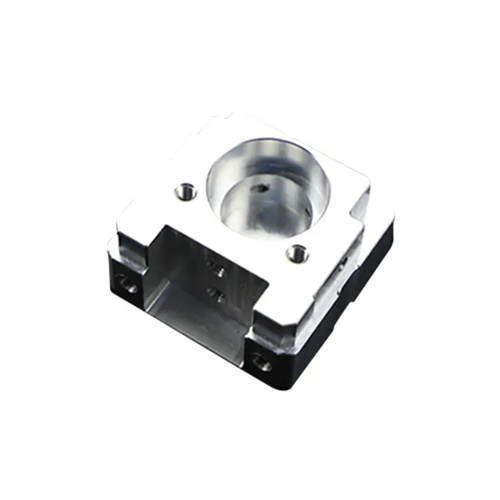

In our CNC Machining Services, aluminum stands out as one of the most versatile metals we work with. Its lightweight nature, combined with good strength and corrosion resistance, makes it an ideal choice for a wide range of applications. When machining aluminum, we take advantage of its relatively soft texture, which allows for high cutting speeds and efficient material removal. Our CNC machines can precisely shape aluminum into intricate components with smooth surface finishes, whether it’s for aerospace parts like aircraft wings and fuselage components, or automotive parts such as engine blocks and wheels. We use specialized cutting tools and optimize machining parameters to prevent issues like burring and tool wear. Additionally, aluminum’s excellent thermal conductivity means we can manage heat generation during machining effectively. With our CNC Machining Services, we can transform aluminum into high-quality, precision parts that meet the strict requirements of various industries, from consumer electronics to sports equipment.

Harnessing the Strength of Steel in CNC Machining Services

Steel is a cornerstone material in our CNC Machining Services, valued for its exceptional strength and durability. When working with different types of steel, such as carbon steel, stainless steel, and alloy steel, we adapt our machining strategies accordingly. Carbon steel, for example, requires careful control of cutting forces and speeds to prevent work hardening, which can damage the cutting tools. Stainless steel, on the other hand, presents challenges due to its tendency to work harden and its poor thermal conductivity. We use high-speed steel or carbide cutting tools with sharp edges and appropriate geometries to machine steel efficiently. For applications like manufacturing industrial machinery components, construction parts, and automotive drivetrain components, our CNC Machining Services ensure that steel parts are produced with tight tolerances and superior surface quality. We also perform heat treatment processes when necessary to enhance the mechanical properties of steel parts, making them suitable for demanding environments.

Mastering the Complexity of Titanium in CNC Machining Services

Titanium is a high-performance metal that offers excellent strength-to-weight ratio and corrosion resistance, but it also poses unique challenges in our CNC Machining Services. Its low thermal conductivity and high chemical reactivity can lead to rapid tool wear and poor chip evacuation during machining. To overcome these issues, we use specialized cutting tools coated with materials like titanium nitride (TiN) or titanium carbide (TiC), which reduce friction and increase tool life. We also carefully select machining parameters, such as low cutting speeds and high feed rates, to optimize the machining process. Titanium is widely used in aerospace, medical, and marine industries, where parts need to withstand extreme conditions. Our CNC Machining Services enable us to produce complex titanium components, such as aircraft engine parts, orthopedic implants, and ship propellers, with the precision and quality required by these industries. By mastering the intricacies of machining titanium, we can provide our clients with high-performance parts that meet their most demanding specifications.

Exploring Other Metals in CNC Machining Services

Beyond aluminum, steel, and titanium, our CNC Machining Services also handle a variety of other metals. Copper, with its excellent electrical and thermal conductivity, is commonly used in electrical components and heat exchangers. We use precision machining techniques to create intricate copper parts with tight tolerances, ensuring optimal performance. Brass, a copper-zinc alloy, is favored for its attractive appearance and good machinability, making it suitable for decorative and plumbing applications. Our CNC machines can produce detailed brass components with high precision. Additionally, we work with precious metals like gold and silver in industries such as jewelry making and electronics. For these materials, our CNC Machining Services focus on achieving fine details and smooth surfaces while minimizing material waste. By expanding our capabilities to include a diverse range of metals, we can meet the unique needs of our clients across different sectors.

Optimizing Processes for Metal CNC Machining Services

To ensure the highest quality and efficiency in our Metal CNC Machining Services, we continuously optimize our processes. We invest in advanced software for toolpath planning and simulation, which helps us identify potential issues and optimize machining parameters before starting production. This reduces the risk of errors and saves time. We also implement tool management systems that monitor tool wear and automatically replace tools when needed, ensuring consistent machining performance. Additionally, we use coolant and lubrication systems effectively to control heat generation, improve chip evacuation, and extend tool life. For different metals, we adjust our machining strategies based on their specific properties, such as hardness, thermal conductivity, and chemical reactivity. By fine-tuning every aspect of the machining process, we can produce metal parts with superior precision, surface finish, and dimensional accuracy, meeting the stringent requirements of our clients.

The Future of Metal CNC Machining Services

As we look to the future, we are excited about the prospects of our Metal CNC Machining Services. Advancements in technology, such as the development of more advanced cutting tools, high-speed machining, and the integration of artificial intelligence, will further enhance our capabilities. New materials and alloys with improved properties are also emerging, presenting both opportunities and challenges for machining. We anticipate that our Metal CNC Machining Services will become even more automated, with robots and intelligent systems assisting in tasks like material handling, tool changing, and quality inspection. This will increase productivity and reduce costs while maintaining high-quality standards. Moreover, as industries continue to demand more complex and high-performance metal components, our services will evolve to meet these needs, enabling us to stay at the forefront of metal machining technology and provide innovative solutions to our clients.