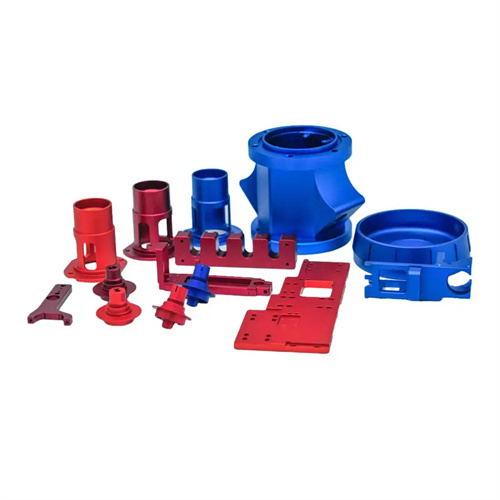

Unleashing Creativity with Custom CNC Machining Services for Metal Products

In our line of work, we firmly believe that Custom CNC Machining Services for Metal Products are a game-changer, especially when it comes to bringing unique ideas to life. With the advanced capabilities of 5-axis CNC machines, we have the freedom to transform concepts into reality, whether it’s for intricate prototypes or low-volume production runs. For instance, designers often come to us with complex visions that require precise geometries and tight tolerances. Our 5-axis CNC machining services allow us to machine brass and stainless steel, two versatile metals, into components with unparalleled detail. From custom jewelry pieces made of brass that demand ornate patterns to stainless-steel parts for high-end machinery with complex internal structures, we can execute designs that traditional machining methods would struggle to achieve. By offering customization, we empower our clients to stand out in the market, as their products can be tailored to specific applications and aesthetic preferences.

Precision at Its Peak with 5-Axis CNC Machining Services for Brass Products

When it comes to working with brass, our 5-Axis CNC Machining Services shine in delivering precision. Brass, with its excellent machinability and attractive appearance, is a popular choice for a wide range of products, from decorative items to functional parts. The 5-axis movement of our CNC machines enables us to access multiple angles and surfaces in a single setup, reducing errors that might occur during multiple setups in conventional machining. For example, when creating detailed brass components for musical instruments, the 5-axis machining allows us to carve out intricate sound chambers and fittings with extreme accuracy. We carefully select the appropriate cutting tools and optimize machining parameters to ensure a smooth surface finish while minimizing material waste. Whether it’s a small brass connector or a large-scale architectural element, our 5-axis CNC machining services guarantee that each brass product meets the highest standards of precision and quality.

Durability and Excellence with 5-Axis CNC Machining Services for Stainless Steel Products

Stainless steel is renowned for its durability and corrosion resistance, and our 5-Axis CNC Machining Services are designed to enhance these qualities in the products we manufacture. Machining stainless steel can be challenging due to its tendency to work harden and poor thermal conductivity, but our 5-axis technology overcomes these obstacles. The ability to perform complex operations in one setup reduces the stress on the material, preventing issues like distortion. In the production of stainless-steel parts for the aerospace and medical industries, where reliability is crucial, our 5-axis CNC machining services ensure that components are fabricated with the utmost precision. We use specialized cutting tools and cooling strategies to manage heat during the machining process, maintaining the integrity of the stainless steel. This results in products that not only meet strict industry standards but also offer long-lasting performance in demanding environments.

Streamlined Production with Custom 5-Axis CNC Machining Services

Efficiency is key in our Custom 5-Axis CNC Machining Services for metal products. We understand that time-to-market is crucial for our clients, especially in competitive industries. The 5-axis capabilities of our CNC machines enable us to perform multiple operations, such as milling, drilling, and turning, in a single setup. This significantly reduces production time compared to traditional machining methods. When working on projects involving a combination of brass and stainless-steel components, we can quickly switch between materials and machining tasks without extensive retooling. Additionally, our use of advanced programming software allows us to optimize toolpaths, further enhancing efficiency. By streamlining the production process, we can handle custom orders of various sizes and complexities, delivering high-quality metal products to our clients in a timely manner.

Rigorous Quality Control in Custom CNC Machining Services for Metal Products

Quality control is an integral part of our Custom CNC Machining Services for Metal Products. We implement a comprehensive quality assurance process to ensure that every brass and stainless-steel component meets or exceeds our clients’ expectations. From the initial material inspection to the final product verification, we use advanced measurement tools, such as coordinate measuring machines (CMMs) and optical scanners, to check dimensional accuracy and surface finish. For brass products, we pay close attention to the aesthetic aspects, ensuring that the finish is flawless. In the case of stainless-steel parts, we conduct tests to verify their mechanical properties and corrosion resistance. Our quality control team also monitors the machining process in real-time, making adjustments as needed to prevent defects. By maintaining strict quality standards, we build trust with our clients and establish a reputation for delivering reliable and top-notch metal products.

The Promising Future of Custom 5-Axis CNC Machining Services for Metal Products

As we look towards the future, we are excited about the prospects of our Custom 5-Axis CNC Machining Services for Metal Products. Technological advancements, such as the integration of artificial intelligence and machine learning, will further enhance the capabilities of our 5-axis CNC machines. These technologies will enable us to predict tool wear, optimize machining parameters in real-time, and improve overall efficiency. The demand for custom metal products, especially those made from brass and stainless steel, is expected to grow across various industries, including automotive, architecture, and consumer goods. We are committed to staying at the forefront of innovation, continuously upgrading our equipment and skills. With our Custom 5-Axis CNC Machining Services, we aim to meet the evolving needs of our clients, offering even more precise, creative, and efficient solutions for metal product manufacturing.