Understanding the Basics of CNC Turning in CNC Machining Services

In our CNC Machining Services, understanding the fundamentals of CNC turning is essential for producing high-quality components. CNC turning is a machining process where the workpiece rotates on a spindle, and cutting tools remove material to create cylindrical shapes, threads, and other rotational features. Our advanced CNC turning machines are programmed with precise instructions that control the movement of the cutting tools, feed rates, and spindle speeds. This automation allows us to achieve consistent accuracy and repeatability in the parts we manufacture. For instance, when creating shafts for automotive transmissions or bolts for aerospace applications, CNC turning enables us to produce parts with tight tolerances and smooth surface finishes. The versatility of CNC turning also allows us to work with a wide range of materials, from metals like steel and aluminum to various plastics. By mastering the basics of CNC turning, we can offer reliable and efficient machining solutions to our clients across different industries.

Exploring the Capabilities of CNC Milling in CNC Machining Services

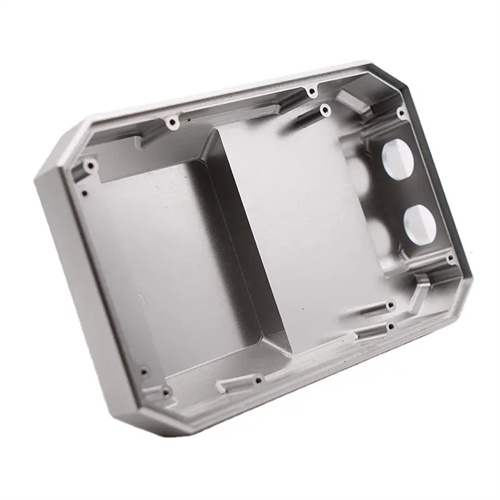

CNC milling is another integral part of our CNC Machining Services, offering a wide array of capabilities for modern manufacturing. Unlike turning, which primarily focuses on rotational parts, CNC milling uses rotary cutters to remove material from the workpiece in multiple directions. This process can create flat surfaces, slots, holes, and complex 3D geometries. Our CNC milling machines are equipped with multiple axes, such as three, four, or five axes, providing the flexibility to machine parts with intricate shapes. For example, in the production of mold components for the plastics industry or parts for high-precision machinery, CNC milling allows us to achieve the required precision and detail. With the help of computer-aided design (CAD) and computer-aided manufacturing (CAM) software, we can generate optimized toolpaths for the milling process, ensuring efficient material removal and minimizing production time. The diverse capabilities of CNC milling make it a crucial process for meeting the complex demands of modern manufacturing.

The Advantages of CNC Turning in CNC Machining Services

Our CNC Machining Services benefit greatly from the numerous advantages of CNC turning. One of the key benefits is its ability to produce parts with high dimensional accuracy. The precise control over the spindle rotation and tool movement ensures that each part meets the exact specifications. Additionally, CNC turning offers excellent surface finish quality, reducing the need for extensive post-processing. This not only saves time but also lowers production costs. Another advantage is the efficiency of CNC turning for manufacturing cylindrical parts in large quantities. Once the programming and setup are complete, our CNC turning machines can rapidly produce identical parts, increasing productivity. Moreover, CNC turning allows for easy customization of parts, as we can quickly modify the machining program to create different features or sizes. These advantages make CNC turning a preferred choice for industries such as automotive, aerospace, and machinery manufacturing when it comes to producing reliable and high-quality rotational components.

The Benefits of CNC Milling in CNC Machining Services

CNC milling brings several significant benefits to our CNC Machining Services. Its versatility in creating complex geometries is a major advantage. We can machine parts with undercuts, deep cavities, and intersecting surfaces that would be difficult or impossible to produce using traditional machining methods. This makes CNC milling ideal for industries like aerospace, where parts often have intricate shapes to optimize performance. The multi-axis capabilities of our CNC milling machines also enable us to perform multiple operations in a single setup, reducing the time and cost associated with repositioning the workpiece. Additionally, CNC milling offers high repeatability, ensuring that each part produced is of consistent quality. By leveraging the benefits of CNC milling, we can provide our clients with parts that not only meet their design requirements but also offer excellent functionality and durability in various applications.

Synergy between CNC Turning and Milling in CNC Machining Services

In our CNC Machining Services, we recognize the powerful synergy between CNC turning and milling. Many components require a combination of both processes to achieve the desired final product. For example, a part may start with a cylindrical shape produced by CNC turning, and then additional features such as slots, holes, or complex contours are added through CNC milling. By integrating these two processes, we can create parts with enhanced functionality and performance. The seamless transition between turning and milling operations also reduces the overall production time, as the workpiece doesn’t need to be transferred between different machines or setups. This synergy allows us to offer comprehensive machining solutions to our clients, handling complex projects from start to finish with precision and efficiency. By utilizing the complementary strengths of CNC turning and milling, we can meet the diverse needs of modern manufacturing and deliver high-quality components that exceed our clients’ expectations.

The Future of CNC Turning and Milling in CNC Machining Services

As we look to the future, we are excited about the prospects of CNC turning and milling in our CNC Machining Services. Technological advancements, such as the integration of artificial intelligence and machine learning, will further enhance the capabilities of these processes. AI can analyze machining data in real-time, optimize toolpaths, and predict tool wear, leading to increased efficiency and reduced costs. Additionally, the development of new cutting tool materials and advanced machine designs will improve the performance and precision of CNC turning and milling. We anticipate that these processes will become even more automated, with robots and cobots assisting in tasks like material handling and tool changing. As industries continue to demand more complex and high-performance components, our CNC Machining Services will evolve to meet these challenges. By staying at the forefront of technological innovation, we are confident that CNC turning and milling will remain key processes in modern manufacturing, enabling us to provide cutting-edge solutions to our clients for years to come.