Unrivaled Flexibility with Custom 5 Axis CNC Machining Services

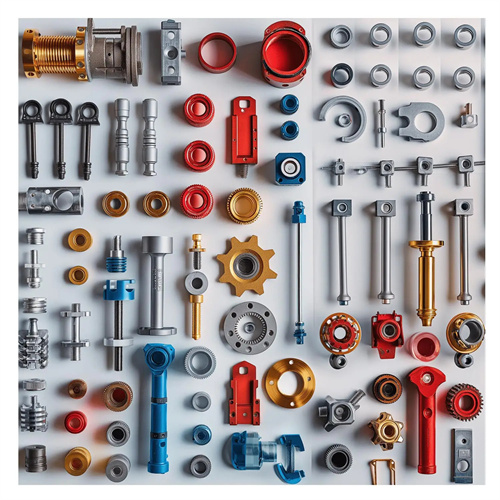

In our line of work, we take pride in offering Custom 5 Axis CNC Machining Services that provide unrivaled flexibility for our clients. The 5-axis technology allows us to approach machining from multiple angles in a single setup, enabling the creation of complex geometries that traditional machining methods struggle to achieve. This flexibility is especially crucial when working on custom projects where unique designs and tight tolerances are the norm. Whether it’s a one-of-a-kind prototype or a low-volume production run of specialized components, our 5-axis CNC machining services can handle it with precision. We can easily adapt to design changes during the production process, reducing lead times and ensuring that our clients’ specific requirements are met. This level of adaptability makes our Custom 5 Axis CNC Machining Services a go-to choice for industries that demand innovation and customization in their metal components.

Mastering Aluminum Machining with Custom 5 Axis CNC Machining Services

Aluminum is a widely used material in our Custom 5 Axis CNC Machining Services, and for good reason. Its lightweight yet strong properties, combined with excellent corrosion resistance, make it suitable for numerous applications. When machining aluminum with our 5-axis CNC machines, we can take full advantage of its relatively soft texture. The multi-axis movement allows us to quickly and accurately shape aluminum into intricate parts, such as aerospace components, automotive parts, and consumer electronics enclosures. We use specialized cutting tools and optimize machining parameters to prevent issues like burring and tool wear, ensuring a smooth surface finish. For example, when creating complex aluminum brackets for aircraft structures, our 5-axis CNC machining services can precisely carve out the necessary contours and holes in a single setup, saving time and improving efficiency. By mastering aluminum machining, we can deliver high-quality custom aluminum parts that meet the strictest industry standards.

Precision Steel Machining with Custom 5 Axis CNC Machining Services

Steel, known for its strength and durability, presents unique challenges and opportunities in our Custom 5 Axis CNC Machining Services. Machining steel requires careful consideration of its hardness and the potential for work hardening. Our 5-axis CNC machines, equipped with advanced cutting tools and precise control systems, are up to the task. We can machine various types of steel, from carbon steel to stainless steel, into components with tight tolerances and superior surface quality. In the manufacturing of industrial machinery parts, automotive drivetrain components, and structural steel elements, our 5-axis CNC machining services shine. The ability to perform multiple operations in one setup reduces the risk of errors and ensures consistent quality. For instance, when producing complex steel gears, our 5-axis technology allows us to cut the teeth with extreme precision, enhancing the performance and longevity of the gears. Through our expertise in precision steel machining, we provide our clients with reliable and robust steel components.

Artistry in Copper Machining with Custom 5 Axis CNC Machining Services

Copper, valued for its excellent electrical and thermal conductivity, is another material that we handle with finesse in our Custom 5 Axis CNC Machining Services. Machining copper requires a delicate touch to maintain its surface integrity and achieve the desired precision. Our 5-axis CNC machines enable us to create intricate copper parts with detailed features, such as electrical connectors, heat exchangers, and decorative items. The multi-axis capabilities allow us to access hard-to-reach areas and perform complex cuts with ease. We use specialized cutting strategies and coolant systems to prevent copper from adhering to the cutting tools and to manage heat generation during machining. This results in copper parts with a smooth finish and precise dimensions. Whether it’s a small copper component for a high-tech device or a large-scale copper structure for industrial use, our 5-axis CNC machining services can bring the design to life with artistry and precision.

Excellence in Brass Machining with Custom 5 Axis CNC Machining Services

Brass, with its attractive appearance and good machinability, is a popular choice in our Custom 5 Axis CNC Machining Services. When machining brass, we leverage the capabilities of our 5-axis CNC machines to produce components with intricate designs and high precision. From decorative brass fixtures for architecture to functional brass parts for plumbing and musical instruments, our 5-axis machining services can handle a wide range of brass applications. The ability to perform multiple operations in a single setup reduces production time and ensures consistent quality. We carefully select cutting tools and optimize machining parameters to prevent issues like tool wear and achieve a smooth surface finish. For example, when creating detailed brass musical instrument parts, our 5-axis CNC machining services can accurately shape the complex internal passages and external contours, enhancing the instrument’s sound quality and performance. Our commitment to excellence in brass machining ensures that our clients receive top-notch custom brass components.

The Future of Custom 5 Axis CNC Machining Services

As we look to the future, we are excited about the prospects of our Custom 5 Axis CNC Machining Services. With the continuous advancement of technology, we expect to see even more capabilities added to our 5-axis CNC machines. The integration of artificial intelligence and machine learning will enable us to optimize machining processes in real-time, predict tool wear, and improve overall efficiency. New materials and alloys will emerge, presenting both challenges and opportunities for machining. We are committed to staying at the forefront of these developments, continuously upgrading our equipment and skills. The demand for custom metal components made from aluminum, steel, copper, and brass is only set to increase across various industries. By investing in research and development and maintaining our focus on quality and customization, we are confident that our Custom 5 Axis CNC Machining Services will play an even more significant role in shaping the future of manufacturing.