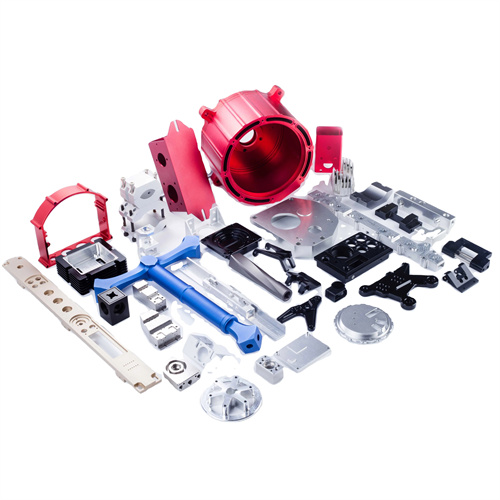

Unmatched Precision with Custom 5 Axis CNC Machining Services for Micro Mechanical Parts

In our Custom CNC Machining Services, the 5 Axis CNC Center stands as a beacon of precision when it comes to crafting micro mechanical parts. Micro mechanical components often demand tolerances in the micrometer range, and traditional machining methods struggle to meet such stringent requirements. However, our 5-axis CNC machining services offer an unparalleled level of accuracy. The simultaneous movement along five axes allows us to access and machine the tiniest of features with utmost precision. For example, in the production of micro gears and sensors, where even the slightest deviation can render the part non-functional, our 5-axis machines can create intricate geometries with exacting detail. The advanced control systems integrated into our CNC centers ensure that each cut is executed with pinpoint accuracy, guaranteeing that every micro mechanical part we produce meets the highest quality standards. This precision not only enhances the performance of the final products but also instills confidence in our clients, who rely on us for their most critical micro machining needs.

Design Flexibility in Custom 5 Axis CNC Machining Services for Micro Mechanical Parts

One of the key strengths of our Custom 5 Axis CNC Machining Services for micro mechanical parts is the remarkable design flexibility it offers. Micro mechanical designs often involve complex internal structures and unconventional shapes that are difficult to achieve through conventional means. Our 5-axis CNC centers empower designers and engineers to push the boundaries of innovation. With the ability to perform multiple operations in a single setup, we can transform even the most intricate designs into reality. Whether it’s a microfluidic chip with labyrinthine channels or a micro robotic component with delicate joints, our 5-axis machining services can handle it. We work closely with our clients during the design phase, providing valuable insights on manufacturability. This collaborative approach, combined with the flexibility of our 5-axis technology, allows us to create custom micro mechanical parts that are not only functional but also optimized for performance and production efficiency.

Material Versatility in Custom 5 Axis CNC Machining Services for Micro Mechanical Parts

Our Custom 5 Axis CNC Machining Services for micro mechanical parts are designed to accommodate a wide range of materials. Micro mechanical applications often require materials with specific properties, such as high strength, corrosion resistance, or biocompatibility. We can machine various metals, including stainless steel, titanium, and aluminum alloys, as well as advanced engineering plastics and composites. For instance, in the medical industry, where micro implants need to be biocompatible and durable, we can precision machine titanium components using our 5-axis CNC centers. In the electronics sector, where lightweight and high-conductive materials are crucial for micro connectors and circuit components, we can work with copper alloys and specialized plastics. By offering material versatility, we ensure that our clients can choose the most suitable material for their micro mechanical parts, enabling us to deliver products that meet the diverse requirements of different industries.

Overcoming Complexity with Custom 5 Axis CNC Machining Services for Micro Mechanical Parts

Micro mechanical parts are often characterized by their complexity, with features that are difficult to access and machine. Our Custom 5 Axis CNC Machining Services are specifically tailored to overcome these challenges. The 5-axis capabilities of our CNC centers allow us to reach hidden and hard-to-reach areas, enabling the machining of parts with undercuts, deep cavities, and intersecting surfaces. For example, in the manufacturing of micro optical components, which require precise shaping of lenses and mirrors with complex geometries, our 5-axis machining services can achieve the necessary precision. We use specialized cutting tools and advanced machining strategies to ensure that each part is processed smoothly, even when dealing with the most intricate designs. By mastering the art of machining complex micro mechanical parts, we have become a trusted partner for industries that demand high-quality, custom-made micro components.

Efficiency and Productivity in Custom 5 Axis CNC Machining Services for Micro Mechanical Parts

Despite the intricate nature of micro mechanical parts, our Custom 5 Axis CNC Machining Services are designed to maximize efficiency and productivity. The 5-axis technology allows us to perform multiple operations, such as milling, drilling, and turning, in a single setup, reducing the time and cost associated with repositioning the workpiece. Our CNC centers are equipped with high-speed spindles and advanced control systems that enable rapid material removal while maintaining precision. Additionally, we use automated tool changers and efficient programming techniques to minimize downtime between operations. For high-volume production runs of micro mechanical parts, our 5-axis machining services can significantly increase throughput without compromising on quality. This combination of efficiency and productivity makes our Custom 5 Axis CNC Machining Services an ideal choice for clients who need to balance precision with cost-effective production.

The Future of Custom 5 Axis CNC Machining Services for Micro Mechanical Parts

As we look ahead, we are excited about the future of our Custom 5 Axis CNC Machining Services for micro mechanical parts. Technological advancements, such as the integration of artificial intelligence and the Internet of Things, are set to revolutionize the micro machining industry. We anticipate that our 5-axis CNC centers will become even more intelligent, with the ability to self-optimize machining processes based on real-time data analysis. New materials and manufacturing techniques will also emerge, presenting both opportunities and challenges. We are committed to staying at the forefront of these developments, continuously investing in research and development to enhance the capabilities of our 5-axis machining services. With the increasing demand for micro mechanical parts in industries such as healthcare, aerospace, and electronics, we are confident that our Custom 5 Axis CNC Machining Services will play an even more significant role in shaping the future of micro manufacturing.