The Core Advantages of High-Speed CNC Machining Services

In our CNC Machining Services, high-speed CNC machining offers a multitude of core advantages that have revolutionized the manufacturing landscape. At the forefront is the 显著 reduction in production time. By operating at higher spindle speeds and feed rates, our high-speed CNC machines can complete machining operations in a fraction of the time compared to traditional CNC machining. This accelerated production not only enables us to meet tight deadlines but also allows for a faster turnaround of projects, giving our clients a competitive edge in the market. Moreover, high-speed machining reduces the overall cost per part as it minimizes labor hours and maximizes machine utilization. Despite the increased speed, our high-speed CNC machining services maintain exceptional precision and surface finish quality, ensuring that the final products meet the most stringent industry standards. This combination of speed, cost-efficiency, and quality makes high-speed CNC machining an invaluable asset in our manufacturing processes.

Technological Foundations of High-Speed CNC Machining Services

The success of our High-Speed CNC Machining Services lies in the robust technological foundations we have established. Our CNC machines are equipped with advanced high-speed spindles capable of reaching rotational speeds of up to 40,000 RPM or even higher. These spindles are designed with precision bearings and advanced cooling systems to ensure stability and reduce heat generation during high-speed operation. Additionally, we utilize high-performance control systems that can rapidly process complex machining programs, enabling smooth and accurate movement of the machine axes at high speeds. Our investment in high-quality linear guides and ball screws further enhances the machine’s rigidity and positioning accuracy. The integration of these cutting-edge technologies provides the necessary framework for our high-speed CNC machining services to deliver fast and precise results, setting us apart in the competitive manufacturing industry.

Process Optimization in High-Speed CNC Machining Services

To fully leverage the capabilities of our High-Speed CNC Machining Services, we focus on comprehensive process optimization. We start by carefully analyzing the part design and material properties to determine the most suitable machining strategies. Our team of experienced engineers uses advanced computer-aided manufacturing (CAM) software to generate optimized toolpaths that minimize non-cutting movements and reduce cycle times. We also select the appropriate cutting tools based on the material being machined and the required surface finish. For high-speed machining, we often use carbide or diamond-coated tools that can withstand the high speeds and forces involved. Additionally, we fine-tune machining parameters such as cutting speed, feed rate, and depth of cut to strike the perfect balance between speed and quality. By continuously optimizing our processes, we ensure that our high-speed CNC machining services operate at peak efficiency while maintaining the highest standards of precision and quality.

Quality Assurance in High-Speed CNC Machining Services

Quality assurance is a top priority in our High-Speed CNC Machining Services, even with the increased production speed. We have implemented a rigorous quality control system that monitors every aspect of the machining process. Before starting production, we conduct thorough inspections of the raw materials to ensure their quality and compliance with specifications. During machining, we use in-process monitoring techniques, such as high-precision sensors and real-time data analysis, to detect any deviations from the desired parameters. Our quality control team regularly checks the dimensions, surface finish, and other critical characteristics of the parts using advanced measuring instruments like coordinate measuring machines (CMMs) and optical scanners. After machining, each part undergoes a final inspection to ensure it meets all the quality requirements. By maintaining strict quality control measures, we can guarantee that our high-speed CNC machining services deliver products of consistent quality, providing our clients with reliable and high-performance components.

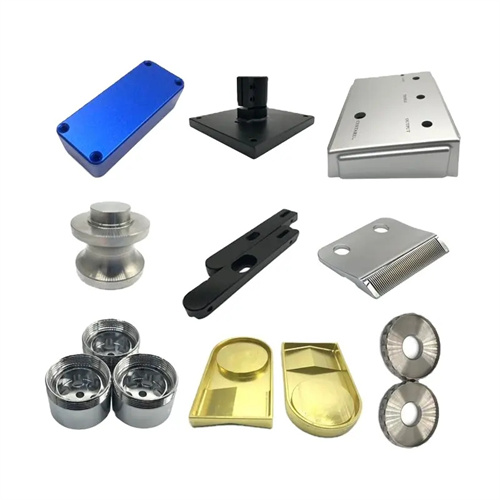

Diverse Applications of High-Speed CNC Machining Services

Our High-Speed CNC Machining Services find wide-ranging applications across various industries. In the aerospace sector, where lightweight and high-strength components are in high demand, high-speed machining enables us to produce complex parts such as turbine blades and structural components quickly and with precision. The automotive industry benefits from our high-speed CNC machining services for manufacturing engine parts, transmission components, and lightweight chassis parts, reducing production times and costs while maintaining quality. In the electronics industry, high-speed machining is essential for producing intricate components like circuit board connectors and heat sinks with tight tolerances. Additionally, our services are utilized in the medical, mold-making, and consumer goods industries. The versatility of our high-speed CNC machining services allows us to meet the diverse needs of these industries, providing them with efficient and high-quality manufacturing solutions.

The Future of High-Speed CNC Machining Services

As we look to the future, we are excited about the prospects of our High-Speed CNC Machining Services. Technological advancements, such as the integration of artificial intelligence (AI) and the Internet of Things (IoT), are set to further enhance the capabilities of high-speed machining. AI algorithms can analyze machining data in real-time, optimize toolpaths, and predict tool wear, leading to even greater efficiency and reduced downtime. The IoT will enable seamless connectivity between machines, allowing for remote monitoring and control, as well as predictive maintenance. We also anticipate the development of new materials and cutting tool technologies that will further improve the performance of high-speed CNC machining. With the increasing demand for faster production cycles and higher-quality products, our high-speed CNC machining services will continue to evolve, enabling us to stay at the forefront of the manufacturing industry and provide our clients with innovative and reliable solutions.