Assessing Machining Capabilities in CNC Machining Services

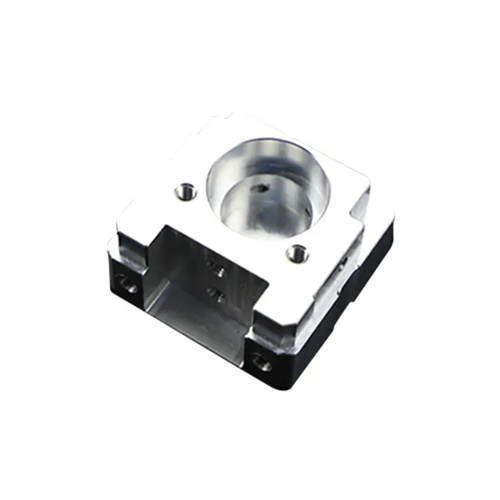

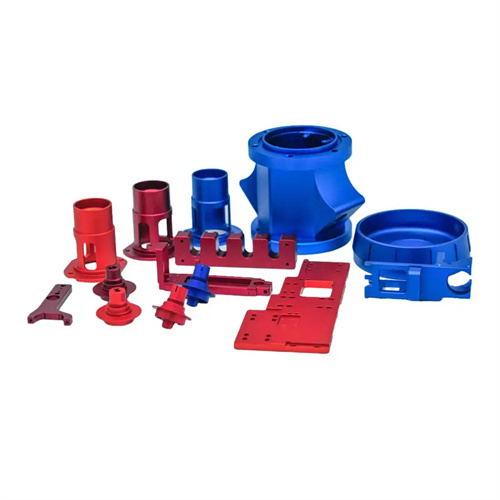

When we embark on the journey to select the right CNC Machining Services provider, assessing their machining capabilities is our first crucial step. We carefully examine the range of machines they possess, as different projects may require specific types of CNC equipment, such as 3-axis, 4-axis, or 5-axis machines. For instance, complex parts with intricate geometries often demand the advanced multi-axis capabilities of 5-axis CNC machines. Additionally, we consider the types of materials the provider can work with. Whether it’s common metals like aluminum, steel, and brass, or more specialized materials such as titanium alloys and engineering plastics, a versatile provider should be able to handle a wide variety of substances. We also look into their expertise in different machining processes, including milling, turning, drilling, and grinding. A provider with diverse machining capabilities is more likely to meet the unique requirements of our projects, ensuring that we can achieve the desired precision and quality in the final components.

Evaluating Quality Control in CNC Machining Services

Quality is non-negotiable in our search for the ideal CNC Machining Services provider, and evaluating their quality control measures is essential. We inquire about the quality management systems they have in place. A reliable provider should have a comprehensive process that starts with the inspection of raw materials to ensure they meet the required standards. During the machining process, in-process monitoring using advanced sensors and measurement tools is a sign of a commitment to quality. We also look for providers who conduct thorough final inspections, employing tools like coordinate measuring machines (CMMs) and optical scanners to verify dimensional accuracy and surface finish. Certifications such as ISO 9001 can be an indication of a provider’s dedication to maintaining high-quality standards. By carefully evaluating their quality control procedures, we can be confident that the parts we receive will be reliable and meet our project’s stringent requirements, reducing the risk of costly rework or product failures.

Considering Cost-Effectiveness in CNC Machining Services

Cost is a significant factor in choosing the right CNC Machining Services provider, and we strive to find a balance between quality and affordability. We request detailed quotes from potential providers, ensuring that all aspects of the project, including material costs, machining time, and any additional services, are clearly outlined. However, we don’t simply opt for the lowest-priced option. Instead, we analyze the cost breakdown to understand how the provider arrives at their pricing. A provider may offer competitive prices due to efficient machining processes, advanced technology, or economies of scale, which are positive indicators. On the other hand, unusually low prices could potentially signal compromises in quality or hidden fees. We also consider the long-term cost implications, such as the durability and performance of the parts, as cheaper components may require more frequent replacements, ultimately increasing overall costs. By carefully considering cost-effectiveness, we can select a provider that offers value for our investment without sacrificing quality.

Reviewing Delivery Capabilities in CNC Machining Services

Timely delivery is crucial for the success of our projects, so reviewing the delivery capabilities of CNC Machining Services providers is a key consideration. We ask about their typical lead times for projects similar to ours and whether they can accommodate any urgent or expedited requests. A provider with a well-organized production schedule and efficient project management processes is more likely to meet deadlines consistently. We also inquire about their shipping and logistics arrangements. They should be able to safely package and deliver the parts to our location within the promised timeframe. Additionally, we look for providers who offer tracking services, allowing us to monitor the progress of our order and plan accordingly. By thoroughly reviewing their delivery capabilities, we can avoid delays in our production cycles and ensure that our projects stay on track.

Examining Technical Support and Service in CNC Machining Services

Technical support and service are often overlooked but vital aspects when choosing a CNC Machining Services provider. We seek out providers who offer assistance throughout the project lifecycle. This includes support during the design phase, where their expertise can help us optimize our designs for manufacturability, reducing potential issues and costs. During production, we value providers who are responsive to our inquiries and can address any unexpected problems promptly. After the parts are delivered, post-sales support, such as handling warranty claims or providing additional machining services if needed, is also important. A provider with a knowledgeable and accessible technical support team demonstrates their commitment to customer satisfaction and can help us navigate any challenges that may arise, ensuring a smooth and successful partnership.

Researching Reputation and Experience in CNC Machining Services

Finally, we conduct thorough research into the reputation and experience of CNC Machining Services providers. We read online reviews and testimonials from previous clients to gain insights into their satisfaction levels and the quality of the provider’s work. References from other businesses in our industry can also provide valuable firsthand information about the provider’s reliability, professionalism, and ability to deliver high-quality results. Additionally, we consider the provider’s years of experience in the field. An established provider with a track record of successful projects is more likely to have encountered and overcome a wide range of challenges, giving us confidence in their ability to handle our unique requirements. By researching their reputation and experience, we can select a provider with a proven history of excellence, increasing the likelihood of a successful and rewarding collaboration.