The Unmatched Advantage of 5-Axis CNC Milling Services in Handling Intricate Geometries

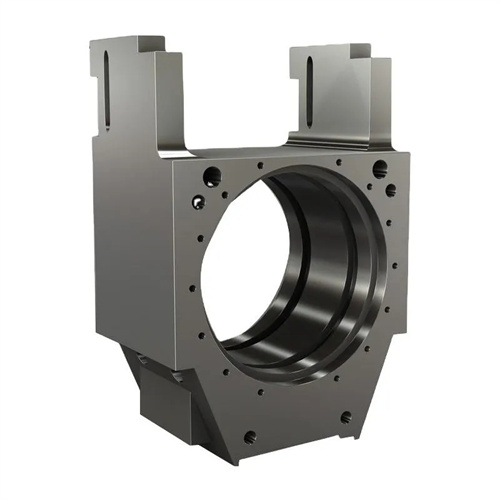

In our CNC Milling Services, 5-axis CNC milling stands out as a game-changer when it comes to machining parts with intricate geometries. Traditional 3-axis milling machines are limited in their ability to access complex angles and surfaces, often requiring multiple setups to complete a single part. However, our 5-axis CNC milling services offer a significant advantage by allowing simultaneous movement along five axes. This enables us to reach every corner and contour of a part in a single setup, eliminating the errors that can accumulate during multiple repositionings. For example, when machining a turbine blade with complex aerofoil shapes and twisted profiles, our 5-axis CNC milling machines can precisely carve out the intricate geometry in one operation. The ability to handle such complex shapes not only improves the accuracy of the parts but also significantly reduces production time, making it an ideal solution for industries that demand high-precision components with elaborate designs.

Understanding the Technical Principles of 5-Axis CNC Milling Services

To fully appreciate the capabilities of our 5-Axis CNC Milling Services, it’s essential to understand the underlying technical principles. A 5-axis CNC milling machine typically combines three linear axes (X, Y, and Z) with two rotational axes (A and B or A and C). These rotational axes allow the cutting tool to approach the workpiece from various angles, providing unparalleled flexibility in machining. Our advanced control systems precisely coordinate the movement of all five axes, ensuring smooth and accurate cutting. We use specialized computer-aided design (CAD) and computer-aided manufacturing (CAM) software to generate toolpaths that take full advantage of the 5-axis capabilities. This software calculates the optimal path for the cutting tool, considering factors such as the part’s geometry, material properties, and tool characteristics. By mastering these technical principles, we can harness the full potential of 5-axis CNC milling to produce parts with the highest level of precision and complexity.

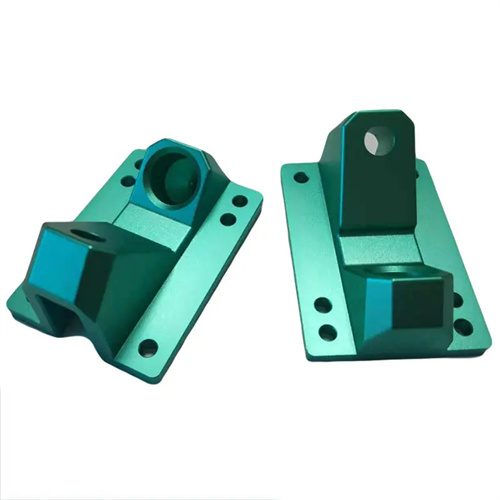

Diverse Applications of 5-Axis CNC Milling Services in Various Industries

Our 5-Axis CNC Milling Services find extensive applications across a wide range of industries. In the aerospace sector, where parts often have complex aerodynamic shapes and require lightweight yet strong structures, 5-axis CNC milling is indispensable. We use it to produce components such as engine compressor blades, wing ribs, and structural brackets with tight tolerances and excellent surface finish. In the medical industry, 5-axis CNC milling is used to create intricate surgical instruments, dental implants, and prosthetics that need to fit precisely with the human body. For example, custom-made knee implants can be milled with 5-axis machines to match the patient’s unique anatomy. The automotive industry also benefits from our 5-axis CNC milling services, especially in the production of high-performance engine parts and complex interior components. These diverse applications highlight the versatility and importance of 5-axis CNC milling in modern manufacturing.

Comparing 5-Axis CNC Milling Services with Traditional Milling Methods

When comparing our 5-Axis CNC Milling Services with traditional 3-axis or 4-axis milling methods, the advantages are clear. Traditional milling often requires multiple setups to machine complex parts, which increases the risk of errors and extends production time. In contrast, 5-axis CNC milling can complete the machining of a part with intricate geometries in a single setup, reducing the overall production cycle. Additionally, 5-axis machines can achieve higher levels of precision and surface finish quality, as the cutting tool can maintain a constant angle and contact with the workpiece throughout the machining process. This results in parts that require less post-processing, saving both time and cost. For parts with undercuts, deep cavities, or complex free-form surfaces, 5-axis CNC milling is the superior choice, offering solutions that traditional milling methods simply cannot match.

Quality Control in 5-Axis CNC Milling Services for Intricate Parts

Quality control is of utmost importance in our 5-Axis CNC Milling Services, especially when machining parts with intricate geometries. We have implemented a comprehensive quality management system to ensure that every part meets the highest standards. Our quality control process begins with a thorough inspection of the raw materials to ensure their quality and compliance with specifications. During the machining process, we use in-process monitoring techniques, such as high-precision sensors and real-time data analysis, to detect any deviations from the desired parameters immediately. After machining, each part undergoes a series of final inspections using advanced measuring tools like coordinate measuring machines (CMMs) and optical scanners. These tools allow us to accurately measure the dimensions, surface finish, and other critical characteristics of the part, ensuring that it meets the exact requirements of our clients. By maintaining strict quality control at every stage, we can provide reliable and high-quality components that are essential for the success of our clients’ products.

The Future of 5-Axis CNC Milling Services

As we look to the future, we are excited about the prospects of our 5-Axis CNC Milling Services. Technological advancements, such as the integration of artificial intelligence (AI) and machine learning (ML), are set to further enhance the capabilities of 5-axis CNC milling. AI and ML algorithms can analyze machining data in real-time, optimize toolpaths, and predict tool wear, leading to increased efficiency and reduced costs. Additionally, the development of new cutting tool materials and advanced machine designs will improve the performance and precision of 5-axis milling. We anticipate that 5-axis CNC milling will become even more accessible and widely used across industries, enabling the production of increasingly complex and innovative parts. By staying at the forefront of these developments and continuously investing in research and development, we are confident that our 5-axis CNC milling services will continue to provide advanced solutions for intricate geometries in the years to come.