Comprehensive Capabilities of Our CNC Milling Services Factory

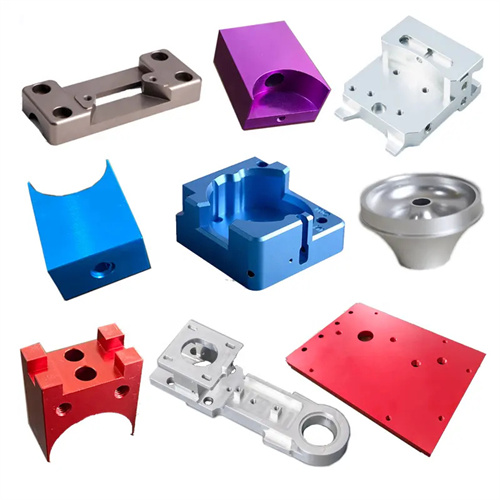

In our CNC Milling Services Factory, we take pride in our comprehensive capabilities that enable us to handle a wide range of projects related to small precision parts. Our factory is equipped with a diverse fleet of state-of-the-art CNC milling machines, each designed to perform specific tasks with utmost precision. From 3-axis to 5-axis machines, we have the equipment necessary to machine parts with varying levels of complexity. Additionally, we have invested in advanced support systems, including computer-aided design (CAD) and computer-aided manufacturing (CAM) software, which allow us to optimize the milling process and ensure accurate results. Our team of skilled engineers and technicians, with years of experience in the field, is well-versed in operating these machines and software. This combination of top-notch equipment and expertise gives us the ability to offer end-to-end solutions, from the initial design concept to the final fabricated and anodized small precision part, all under one roof.

Precision Milling Fabrication in Our CNC Milling Services Factory

Precision milling fabrication is at the heart of our CNC Milling Services Factory, especially when it comes to small parts. These parts often require tolerances in the micrometer range, and our CNC milling machines are up to the challenge. We use high-precision cutting tools and advanced machining techniques to shape materials such as metals, plastics, and composites into the desired form. For example, when fabricating small components for the electronics industry, like connectors or heat sinks, our machines can create intricate geometries with exacting detail. The multi-axis capabilities of our CNC milling equipment allow us to access complex angles and surfaces in a single setup, reducing errors that could occur during multiple repositionings. We also carefully optimize machining parameters, including cutting speed, feed rate, and depth of cut, based on the material properties and the specific requirements of each part. This meticulous approach to precision milling fabrication ensures that every small part we produce meets the strictest quality and accuracy standards.

Anodizing Excellence in Our CNC Milling Services Factory

Anodizing is a key service offered in our CNC Milling Services Factory, enhancing the quality and functionality of the small precision parts we fabricate. Anodizing not only improves the corrosion resistance and wear properties of metals like aluminum but also provides a range of aesthetic options. Our factory has a dedicated anodizing facility equipped with advanced tanks and processing systems. We offer various anodizing techniques, including sulfuric acid anodizing, chromic acid anodizing, and hard anodizing, depending on the specific needs of our clients. Our technicians are trained to control the anodizing process precisely, ensuring a uniform and durable anodized layer. For instance, when anodizing small aluminum parts for the automotive or aerospace industry, we can achieve the desired thickness, color, and surface finish. This anodizing excellence not only adds value to the parts but also makes them more suitable for demanding applications, safeguarding their performance and longevity.

Rigorous Quality Control in Our CNC Milling Services Factory

Quality control is an integral and non-negotiable part of our operations in the CNC Milling Services Factory. We have established a rigorous quality management system to ensure that every small precision part, from the milled and fabricated stage to the anodized finish, meets the highest standards. Our quality control process begins with the inspection of raw materials, verifying their composition, mechanical properties, and compliance with industry specifications. During the milling fabrication process, in-process monitoring is carried out using high-precision sensors and real-time data analysis to detect any deviations from the desired machining parameters immediately. After fabrication, parts undergo dimensional inspections using advanced measuring tools like coordinate measuring machines (CMMs) and optical scanners. For anodized parts, we check the uniformity, thickness, and appearance of the anodized layer. By maintaining such strict quality control at every stage, we can guarantee that our small precision parts are reliable, consistent, and meet the expectations of our clients in various industries.

Integrated Solutions in Our CNC Milling Services Factory

In our CNC Milling Services Factory, we offer integrated solutions that combine milling fabrication and anodizing, providing our clients with a seamless experience. Instead of outsourcing different aspects of the production process, our clients can rely on us to handle everything from machining the small precision parts to applying the final anodized finish. This integration not only saves time but also reduces the risk of errors that could occur during the transfer of parts between different suppliers. For example, we can ensure that the dimensions of the milled part are maintained throughout the anodizing process, as our team has full control over both stages. Moreover, our ability to offer customized solutions, tailoring the milling and anodizing processes to the specific requirements of each project, further enhances the value we provide. By offering these integrated solutions, we aim to be the one-stop destination for our clients’ small precision part manufacturing needs.

The Future of Our CNC Milling Services Factory

As we look to the future, we are excited about the prospects of our CNC Milling Services Factory. Technological advancements, such as the development of more intelligent CNC milling machines with enhanced automation capabilities and the integration of artificial intelligence into the manufacturing process, will open up new possibilities. We plan to invest in these emerging technologies to further improve the precision, efficiency, and productivity of our operations. For anodizing, we anticipate the emergence of new and more environmentally friendly processes, and we are committed to adopting these advancements. Additionally, as industries continue to demand smaller, more complex, and higher-precision parts, we will focus on continuously upgrading our skills and equipment to meet these evolving needs. By staying at the forefront of innovation and maintaining our commitment to quality, we are confident that our CNC Milling Services Factory will continue to thrive and provide exceptional services to our clients in the years to come.