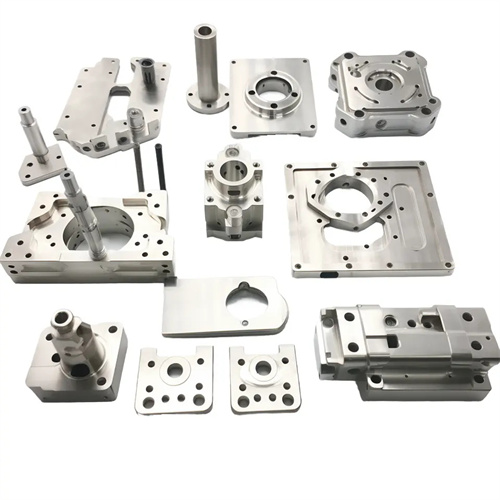

Robust Capabilities of Our CNC Milling Services Lathe Manufacturer

In our CNC Milling Services Lathe Manufacturer, we possess robust capabilities that empower us to take on the most challenging projects related to custom complex metal parts. Our manufacturing facility is outfitted with a sophisticated lineup of CNC milling machines and lathes, ranging from basic 3-axis models to advanced 5-axis and multi-axis machines. These state-of-the-art machines are engineered to deliver unparalleled precision and performance, enabling us to machine a diverse array of metals, including steel, aluminum, titanium, and various alloys. Alongside our cutting-edge equipment, we have invested in advanced software systems for design and manufacturing, such as computer-aided design (CAD), computer-aided manufacturing (CAM), and computer-aided engineering (CAE). Our team of highly skilled engineers, technicians, and operators, with extensive experience in the metalworking industry, proficiently operate these machines and software. This combination of top-tier equipment, advanced software, and skilled personnel allows us to offer comprehensive solutions for custom complex metal parts, from the initial concept design to the final production, all within our facility.

Precision-Driven CNC Milling Services for Complex Metal Parts

Precision is the cornerstone of our CNC Milling Services when it comes to fabricating complex metal parts. Complex geometries, intricate contours, and tight tolerances are the norm for these parts, and our CNC milling machines are specifically designed to meet these exacting requirements. We utilize high-precision cutting tools with specialized coatings and geometries to ensure efficient material removal and accurate cuts. For example, when machining aerospace components with complex aerodynamic shapes or medical implants with intricate internal structures, our multi-axis CNC milling machines can access every angle and surface in a single setup, minimizing errors that could occur during multiple repositionings. Our engineers carefully optimize machining parameters, including cutting speed, feed rate, and depth of cut, based on the specific metal material and part design. Through continuous monitoring and adjustment during the milling process, we guarantee that each complex metal part we produce adheres to the strictest quality and dimensional accuracy standards, meeting and often exceeding our clients’ expectations.

Mastery of Lathe Operations in Our CNC Milling Services

In addition to our exceptional CNC Milling Services, our proficiency in lathe operations sets us apart in the manufacturing of custom complex metal parts. Lathes are essential for creating cylindrical components, threads, and parts with rotational symmetry, and we have mastered the art of operating both traditional and CNC lathes. Our CNC lathes are equipped with advanced control systems that enable precise control over the spindle speed, feed rate, and tool movement. This allows us to produce parts with high surface finish quality and tight tolerances, even for complex shapes with varying diameters and tapers. For instance, when manufacturing shafts for industrial machinery or high-precision bolts for the automotive industry, our lathe operators can achieve the required precision and consistency. We also leverage the capabilities of live tooling on our CNC lathes, which enables us to perform additional operations such as milling, drilling, and tapping in a single setup, further enhancing the complexity and functionality of the parts we produce. Our expertise in lathe operations, combined with our CNC milling services, provides a comprehensive solution for a wide range of custom complex metal parts.

Customization Expertise in Our CNC Milling Services for Complex Metal Parts

Customization is at the heart of our CNC Milling Services for complex metal parts. We understand that each client’s project is unique, with specific requirements for design, functionality, and performance. Our team of experienced designers and engineers works closely with clients from the very beginning, listening to their needs and translating their ideas into detailed design concepts. Using CAD software, we create 3D models of the custom complex metal parts, allowing clients to visualize the final product and make any necessary adjustments. Once the design is approved, our CAM software generates optimized machining programs for our CNC milling machines and lathes. Throughout the production process, we maintain open communication with clients, providing regular updates on the progress of their projects. Whether it’s a one-of-a-kind prototype or a large-scale production run of customized parts, we have the flexibility and expertise to meet the diverse needs of our clients, ensuring that each custom complex metal part is tailored to their exact specifications.

Rigorous Quality Assurance in Our CNC Milling Services Lathe Manufacturer

Quality assurance is an unwavering commitment in our CNC Milling Services Lathe Manufacturer. We have implemented a comprehensive quality management system that encompasses every stage of the production process for custom complex metal parts. Starting with the sourcing of raw materials, we conduct thorough inspections to verify their chemical composition, mechanical properties, and compliance with industry standards. During the machining process, in-process monitoring is carried out using high-precision sensors and real-time data analysis to detect any deviations from the desired machining parameters immediately. After the parts are machined, they undergo a series of rigorous final inspections. We utilize advanced measuring instruments such as coordinate measuring machines (CMMs), optical comparators, and surface roughness testers to assess dimensional accuracy, surface finish, and other critical characteristics. For parts with specific functional requirements, we perform additional tests, such as hardness testing, tensile testing, and non-destructive testing. By maintaining strict quality control at every step, we ensure that the custom complex metal parts we produce are reliable, durable, and meet the highest quality standards, providing our clients with products they can trust.

Future Prospects of Our CNC Milling Services Lathe Manufacturer

As we look towards the future, we are filled with excitement about the prospects of our CNC Milling Services Lathe Manufacturer. Technological advancements, such as the integration of artificial intelligence (AI), the Internet of Things (IoT), and robotics into the manufacturing process, are set to revolutionize the industry. We plan to embrace these emerging technologies, leveraging AI algorithms to optimize machining parameters in real-time, predict tool wear, and improve overall efficiency. IoT-enabled machines will allow us to monitor and control our CNC milling machines and lathes remotely, enabling predictive maintenance and reducing downtime. The adoption of robotics will enhance our automation capabilities, increasing productivity and reducing labor costs. Additionally, as industries continue to demand more complex, high-performance, and lightweight metal parts, we will focus on continuous research and development, exploring new materials, machining techniques, and manufacturing processes. By staying at the forefront of innovation and maintaining our commitment to quality and customer satisfaction, we are confident that our CNC Milling Services Lathe Manufacturer will continue to grow and thrive, providing cutting-edge solutions for custom complex metal parts in the years to come.