The Ideal Material Choice: Aluminum in Our CNC Milling Services

In our CNC Milling Services, aluminum stands out as an ideal material for custom metal prototypes, especially when rapid prototyping is required. Aluminum’s lightweight yet robust nature makes it a popular choice across various industries. Its excellent strength-to-weight ratio allows for the creation of durable prototypes without adding unnecessary bulk, which is crucial for applications in aerospace, automotive, and electronics. Additionally, aluminum is highly malleable and has good machinability. This means that our CNC milling machines can quickly and efficiently shape it into the desired form, reducing the overall production time for prototypes. Its corrosion resistance also ensures that the prototypes maintain their integrity during the testing and evaluation phases. Whether it’s a small component for a consumer electronics device or a large structural part for an automotive prototype, aluminum provides the perfect balance of performance, cost, and ease of machining in our CNC Milling Services.

Precision at the Core of Aluminum Prototype CNC Milling Services

Precision is the cornerstone of our Aluminum Prototype CNC Milling Services. When creating prototypes, even minor inaccuracies can lead to significant issues during the product development process. Our state-of-the-art CNC milling machines are equipped with advanced control systems that can achieve tolerances within extremely tight ranges. This level of precision ensures that the prototypes we produce are exact replicas of the intended design, allowing for accurate testing and validation. For example, in the development of complex aerospace components, where every millimeter matters, our CNC milling services can create aluminum prototypes with the precision needed to simulate real-world performance. The use of high-quality cutting tools and optimized machining parameters further enhances the precision, ensuring that each prototype meets the strict specifications set by our clients. This commitment to precision not only saves time by reducing the need for rework but also provides our clients with confidence in the reliability of the prototypes.

Rapid Prototyping Capabilities in Our CNC Milling Services

Rapid prototyping is a key strength of our CNC Milling Services, especially when working with aluminum. We understand that in today’s competitive market, speed is of the essence. Our streamlined processes and advanced technology enable us to produce aluminum prototypes in a fraction of the time compared to traditional methods. Once the design is finalized using computer-aided design (CAD) software, our computer-aided manufacturing (CAM) systems quickly generate the machining programs for our CNC milling machines. These machines can then start production immediately, often completing the prototype within a short turnaround time. For urgent projects, we can even prioritize orders and expedite the prototyping process without compromising on quality. This rapid prototyping capability allows our clients to quickly test their ideas, make necessary design adjustments, and move forward with product development at an accelerated pace.

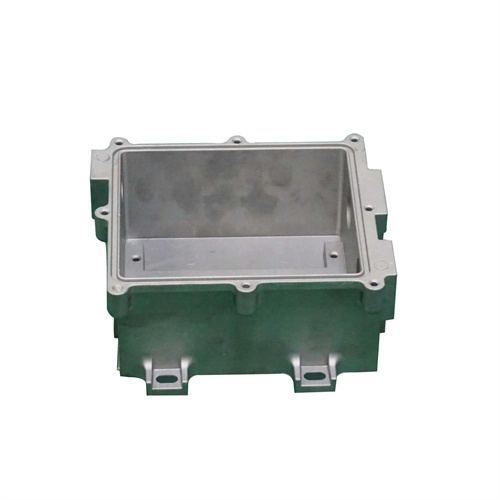

Design Flexibility in Aluminum Prototype CNC Milling Services

Our Aluminum Prototype CNC Milling Services offer unparalleled design flexibility. With the use of multi-axis CNC milling machines, we can handle complex geometries and intricate designs with ease. Whether it’s creating parts with undercuts, deep cavities, or free-form surfaces, our machines can access all angles of the aluminum workpiece in a single setup. This eliminates the need for multiple setups and reduces the potential for errors. Additionally, our team of experienced engineers and designers can work closely with clients to optimize the design for manufacturability. We can provide valuable insights on material usage, machining feasibility, and cost-saving measures without sacrificing the integrity of the design. This collaborative approach ensures that the aluminum prototypes we produce not only meet the client’s aesthetic and functional requirements but also can be efficiently manufactured on a larger scale if needed.

Cost-Effective Solutions in Our CNC Milling Services for Aluminum Prototypes

Contrary to what some might assume, our CNC Milling Services for aluminum prototypes offer cost-effective solutions. While the initial investment in CNC milling technology might seem high, the long-term savings are significant. For prototype production, aluminum is a relatively affordable material compared to some other metals, and its good machinability reduces the machining time and associated costs. Our ability to perform multiple operations in a single setup with our CNC milling machines also eliminates the need for additional tooling and setup time, further cutting costs. Moreover, the precision of our CNC milling services reduces the likelihood of errors, minimizing the need for costly rework. For clients looking to develop multiple prototypes or test different design iterations, our cost-effective approach allows them to achieve their goals without overspending, making our CNC Milling Services an attractive option for aluminum prototype production.

Quality Assurance in Aluminum Prototype CNC Milling Services

Quality assurance is an integral part of our Aluminum Prototype CNC Milling Services. We have a comprehensive quality management system in place to ensure that every prototype we produce meets the highest standards. Our quality control process starts with the selection of high-quality aluminum materials, which are carefully inspected for their chemical composition and mechanical properties. During the machining process, we use in-process monitoring techniques, such as real-time measurement and data analysis, to detect and correct any deviations from the desired specifications immediately. After machining, each prototype undergoes a thorough final inspection using advanced measuring instruments like coordinate measuring machines (CMMs) and optical scanners. These tools allow us to accurately assess the dimensions, surface finish, and other critical characteristics of the prototype. By maintaining strict quality control at every stage, we can provide our clients with aluminum prototypes that are not only functional and reliable but also ready for rigorous testing and evaluation.