The Surging Demand for CNC Milling Services in Aluminum Machined Parts

In our CNC Milling Services, we have witnessed a surging demand for customized anodizing aluminum machined parts across multiple industries. The unique properties of aluminum, such as its lightweight nature, excellent corrosion resistance, and high strength-to-weight ratio, make it a preferred material for countless applications. In the automotive industry, there is a growing need for lightweight aluminum components to improve fuel efficiency and performance, while the electronics sector requires precisely machined aluminum parts for heat dissipation and device enclosures. Anodizing, which enhances the material’s durability and aesthetic appeal, adds an extra layer of value. As a result, manufacturers across various fields are turning to our CNC milling services to produce high-quality, customized aluminum parts with anodized finishes. This increasing demand drives us to continuously optimize our processes and invest in advanced technologies to meet the evolving needs of our clients.

Precision and Efficiency in Our CNC Milling Services for Aluminum Parts

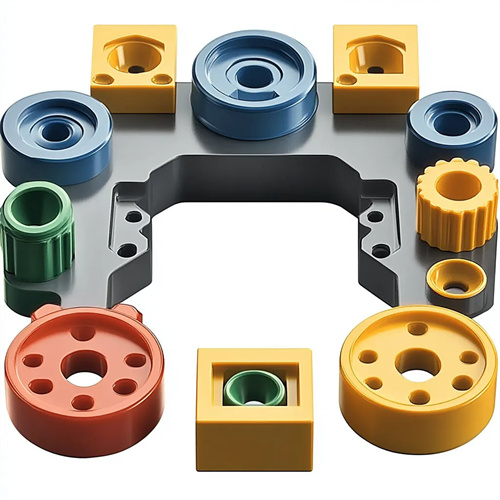

Precision and efficiency are the hallmarks of our CNC Milling Services when it comes to machining aluminum parts. Our state-of-the-art CNC milling machines are equipped with advanced control systems that can achieve extremely tight tolerances, ensuring that each aluminum part meets the exact specifications of our clients. Whether it’s creating intricate geometries for aerospace components or simple yet precise parts for consumer products, our machines can handle the task with ease. We use high-quality cutting tools and optimize machining parameters, such as cutting speed, feed rate, and depth of cut, to ensure efficient material removal while maintaining surface finish quality. Additionally, our experienced operators and engineers work closely together to streamline the machining process, reducing setup times and minimizing production delays. This combination of precision and efficiency allows us to produce large volumes of customized aluminum parts in a timely manner, meeting the high demand in the market.

Customized Anodizing Expertise in Our CNC Milling Services

Our CNC Milling Services are not only about machining aluminum parts but also about providing customized anodizing solutions. Anodizing is a crucial process that can significantly enhance the performance and appearance of aluminum components. We offer a wide range of anodizing options, including different colors, textures, and thicknesses, to meet the diverse requirements of our clients. Our anodizing facility is equipped with advanced tanks, filtration systems, and monitoring equipment to ensure consistent and high-quality results. Our technicians are well-trained in various anodizing techniques, such as sulfuric acid anodizing, hard anodizing, and chromic acid anodizing. They carefully control the anodizing process, adjusting parameters like voltage, temperature, and time to achieve the desired finish. Whether it’s a sleek, glossy surface for a consumer product or a durable, hard-coated finish for an industrial application, our customized anodizing expertise in CNC milling services can bring our clients’ visions to life.

Rigorous Quality Control in Our CNC Milling Services for Anodized Aluminum Parts

Quality control is an integral part of our CNC Milling Services for anodized aluminum parts. We understand that even the slightest defect in a part can have a significant impact on its performance and the overall success of our clients’ products. To ensure the highest quality, we have implemented a comprehensive quality management system. Our process begins with the careful selection of high-quality aluminum raw materials, which are thoroughly inspected for their chemical composition and mechanical properties. During the machining process, in-process monitoring using sensors and real-time data analysis helps us detect and correct any deviations from the desired specifications immediately. After machining, the parts undergo a series of inspections, including dimensional checks, surface finish evaluations, and non-destructive testing. For the anodizing process, we closely monitor the quality of the anodized layer, checking its thickness, uniformity, and color. By maintaining strict quality control at every stage, we can provide our clients with anodized aluminum parts that are reliable, durable, and meet the most stringent industry standards.

Diverse Applications of Our CNC Milling Services for Anodized Aluminum Parts

Our CNC Milling Services for anodized aluminum parts find applications in a wide variety of industries. In the aerospace industry, anodized aluminum parts are used for structural components, engine parts, and interior furnishings, where their lightweight and corrosion-resistant properties are highly valued. The automotive industry utilizes our parts for body panels, wheels, and engine components, enhancing both the performance and appearance of vehicles. In the electronics sector, anodized aluminum enclosures provide excellent protection for sensitive components while also offering an attractive aesthetic. Additionally, our parts are used in the architecture, medical, and consumer goods industries. For example, in architecture, anodized aluminum is used for building facades, railings, and decorative elements, adding a touch of elegance and durability. Our ability to meet the diverse needs of these industries showcases the versatility of our CNC milling services for customized anodizing aluminum machined parts.

The Future of Our High Demand CNC Milling Services

Looking ahead, we are excited about the future of our high demand CNC Milling Services for customized anodizing aluminum machined parts. Technological advancements, such as the development of more advanced CNC milling machines with higher precision and faster processing speeds, will further enhance our capabilities. The integration of artificial intelligence and machine learning into our manufacturing processes will enable us to optimize machining and anodizing parameters in real-time, improving efficiency and reducing costs. New anodizing techniques and environmentally friendly processes are also likely to emerge, allowing us to offer even more innovative solutions to our clients. As industries continue to grow and evolve, the demand for high-quality, customized aluminum parts with anodized finishes will only increase. We are committed to staying at the forefront of these developments, continuously investing in research and development, and upgrading our equipment and skills to meet the future needs of our clients.