Robust Quality Management System in Our CNC Milling Services

In our CNC Milling Services for medical devices, a robust quality management system forms the bedrock for meeting strict industry standards. The medical field demands products of the highest reliability and safety, and we leave no room for compromise. We adhere to international standards such as ISO 13485, which sets out specific requirements for quality management in the medical device industry. Our quality management system encompasses every aspect of the CNC milling process, from the initial design review to the final product release. We have established detailed standard operating procedures (SOPs) for each step, ensuring consistency and traceability. Regular internal audits and management reviews are conducted to identify areas for improvement and ensure compliance. By maintaining this comprehensive quality management system, we can guarantee that our CNC milled medical devices meet the stringent expectations of regulatory bodies and healthcare professionals.

Stringent Material Control in Our CNC Milling Services

Material control is a critical component of our CNC Milling Services for medical devices. Only materials that are proven to be biocompatible, non-toxic, and stable in the human body are suitable for medical applications. We source materials from trusted suppliers who can provide comprehensive documentation, including certificates of conformity and material traceability records. Before machining, every batch of material undergoes rigorous inspection, including chemical composition analysis, mechanical property testing, and biocompatibility assessment. For example, when using titanium alloys for orthopedic implants, we ensure that they meet the ASTM standards for surgical implants. By exercising such stringent control over materials, we eliminate the risk of adverse reactions in patients and ensure the long – term performance of the medical devices we produce through our CNC milling services.

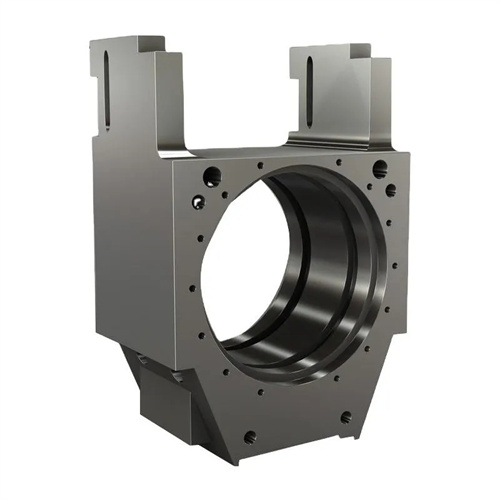

Precision – Driven Machining in Our CNC Milling Services

Precision is of utmost importance in our CNC Milling Services for medical devices, as even the slightest deviation can have significant consequences. Medical devices often require extremely tight tolerances, sometimes within the micrometer range. Our state – of – the – art CNC milling machines, equipped with high – precision control systems and advanced sensors, are capable of achieving such exacting standards. We use computer – aided design (CAD) and computer – aided manufacturing (CAM) software to generate highly accurate toolpaths. Our experienced engineers fine – tune machining parameters, such as cutting speed, feed rate, and depth of cut, based on the material properties and part design. For complex medical components like dental implants or surgical instruments with intricate geometries, our multi – axis CNC milling machines can access all angles and surfaces in a single setup, ensuring dimensional accuracy and surface finish quality. This precision – driven approach is essential for the proper fit, function, and safety of medical devices.

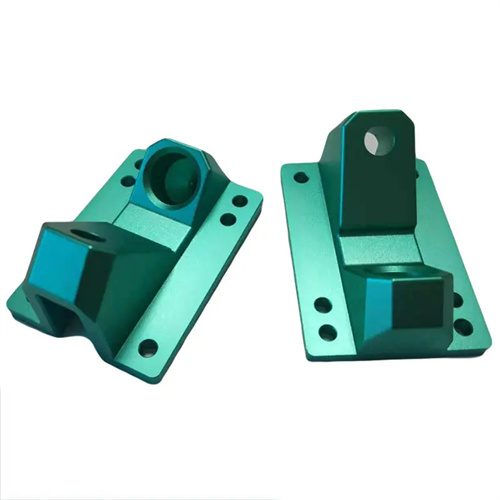

Specialized Surface Finishing in Our CNC Milling Services

Surface finishing in our CNC Milling Services for medical devices is not just an aesthetic consideration but a crucial requirement for functionality and safety. A smooth surface finish is essential to prevent the accumulation of bacteria and to ensure easy cleaning and sterilization. We offer a range of specialized surface finishing techniques tailored to medical applications. For example, electropolishing is commonly used to remove surface imperfections, improve corrosion resistance, and create a smooth, mirror – like finish on stainless – steel surgical instruments. For implants, surface treatments such as sandblasting or acid – etching can be applied to promote osseointegration, the process by which the implant fuses with the surrounding bone tissue. Our technicians are highly skilled in these surface finishing methods and strictly follow industry guidelines to ensure that the surface properties of the medical devices meet the required standards.

Comprehensive Validation and Testing in Our CNC Milling Services

Comprehensive validation and testing are integral to our CNC Milling Services for medical devices to ensure compliance with strict industry standards. We conduct a series of tests, including dimensional inspections, functional tests, and biocompatibility evaluations. Dimensional inspections are carried out using advanced measuring instruments such as coordinate measuring machines (CMMs) to verify that the parts meet the design specifications. Functional tests simulate the real – world use of the medical devices to ensure their proper operation. Biocompatibility testing, which may include cytotoxicity, genotoxicity, and sensitization tests, is performed to confirm that the devices do not cause adverse reactions in the human body. Additionally, we conduct sterilization validation to ensure that the medical devices can be effectively sterilized using methods such as steam sterilization, ethylene oxide sterilization, or gamma irradiation. These thorough validation and testing processes give us and our clients confidence in the safety and effectiveness of the CNC milled medical devices.

Continuous Improvement in Our CNC Milling Services

In our CNC Milling Services for medical devices, continuous improvement is a constant pursuit to keep up with evolving industry standards. The medical device industry is constantly advancing, with new materials, technologies, and regulatory requirements emerging regularly. We invest in ongoing training for our staff to keep them updated on the latest developments. Our research and development team explores new machining techniques and materials that can enhance the performance and quality of medical devices. We also actively seek feedback from our clients and regulatory authorities to identify areas for improvement. By continuously refining our processes, upgrading our equipment, and enhancing our skills, we ensure that our CNC milling services for medical devices not only meet but exceed the strict industry standards, contributing to the advancement of healthcare.