Advanced Equipment and Technology in Our CNC Milling Services

In our CNC Milling Services, advanced equipment and technology are the foundation for machining complex metal and plastic parts. We have invested in a diverse range of state-of-the-art CNC milling machines, including multi-axis models such as 4-axis and 5-axis machines. These machines offer unparalleled flexibility, enabling us to access multiple angles and surfaces of a workpiece in a single setup, which is crucial for manufacturing complex geometries. Our high-speed spindles, capable of reaching up to 40,000 RPM, ensure efficient material removal while maintaining precision. Additionally, we utilize advanced computer-aided design (CAD) and computer-aided manufacturing (CAM) software. CAD software allows for the creation of detailed 3D models of complex parts, while CAM software generates optimized toolpaths, taking into account factors like material properties, cutting forces, and machine capabilities. This combination of cutting-edge equipment and software empowers us to handle the most challenging projects involving complex metal and plastic parts with ease.

Mastery of Metal and Plastic Machining in Our CNC Milling Services

Our CNC Milling Services showcase our mastery in machining both complex metal and plastic parts. Metals, such as stainless steel, titanium, and aluminum alloys, present unique challenges due to their varying hardness, thermal conductivity, and work-hardening characteristics. For example, when machining titanium, its low thermal conductivity can cause heat buildup, leading to tool wear. We address this by using specialized cutting tools with appropriate coatings and optimizing machining parameters like cutting speed and feed rate. On the other hand, plastics have their own set of requirements. Some plastics are prone to melting or warping under high heat, so we carefully control the cutting temperature and use sharp tools to prevent material deformation. Whether it’s creating intricate metal components for aerospace applications or complex plastic parts for the electronics industry, our in-depth understanding of these materials’ properties allows us to achieve the desired precision and surface finish, meeting the high standards of our clients.

Ensuring Precision in Our CNC Milling Services for Complex Parts

Precision is the cornerstone of our CNC Milling Services, especially when dealing with complex metal and plastic parts. Even the smallest deviation in dimensions can render a part unusable, particularly in industries like medical and aerospace. To ensure precision, we rely on high-precision linear guides and ball screws in our CNC machines, which provide smooth and accurate movement of the machine axes. Our machines are also equipped with high-resolution encoders that constantly monitor the position of the cutting tool, enabling real-time adjustments to maintain accuracy. During the machining process, we use in-process measurement techniques, such as touch probes, to check the dimensions of the part at various stages and make any necessary corrections. After machining, we conduct thorough final inspections using advanced measuring instruments like coordinate measuring machines (CMMs) and optical scanners. This comprehensive approach to precision control guarantees that every complex part we produce meets the exact specifications, ensuring its functionality and compatibility within the final product.

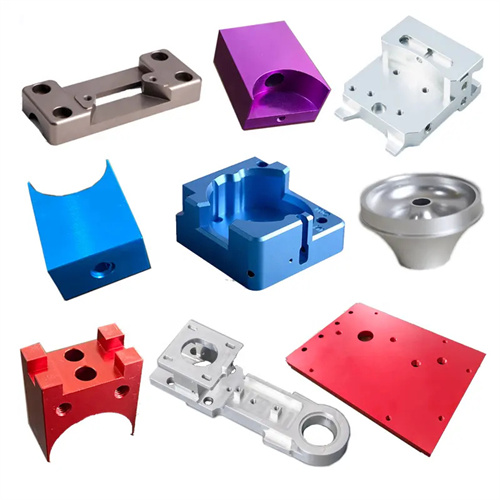

Customization Capabilities in Our CNC Milling Services for Complex Parts

Our CNC Milling Services offer extensive customization capabilities for complex metal and plastic parts. We understand that each project has unique requirements, and a one-size-fits-all approach is not suitable. From the initial design consultation, our team of experienced engineers and designers works closely with clients to understand their needs, product functionality, and aesthetic preferences. Using CAD software, we can create customized 3D models that incorporate specific features, such as undercuts, deep cavities, or intricate patterns. Our multi-axis CNC milling machines then bring these designs to life with precision. For example, in the automotive industry, we can customize metal engine components or plastic interior parts according to the client’s specific design requirements. Whether it’s a small batch of custom parts or a large-scale production run, our ability to provide tailored solutions ensures that our clients receive products that are perfectly suited to their applications.

Rigorous Quality Control in Our CNC Milling Services

Quality control is an integral part of our CNC Milling Services for complex metal and plastic parts. We have established a comprehensive quality management system that adheres to international standards, such as ISO 9001. Our quality control process begins with the inspection of raw materials. We verify the chemical composition, mechanical properties, and certifications of metals and plastics to ensure their suitability for the project. During machining, in-process inspections are carried out regularly to detect any potential issues, such as tool wear or dimensional variations. After machining, each part undergoes a series of final inspections, including visual inspections, dimensional checks, and surface finish evaluations. For critical parts, we also perform non-destructive testing, such as ultrasonic testing for metals, to ensure internal integrity. By maintaining strict quality control at every stage, we can provide our clients with high-quality complex parts that are reliable and meet their expectations.

The Future of Our CNC Milling Services for Complex Parts

As we look to the future, we are excited about the prospects of our CNC Milling Services for complex metal and plastic parts. Technological advancements, such as the integration of artificial intelligence (AI) and machine learning (ML), are set to revolutionize the manufacturing industry. AI and ML algorithms can analyze machining data in real-time, optimize toolpaths, and predict tool wear, leading to increased efficiency and reduced costs. New materials with enhanced properties are also likely to emerge, presenting new opportunities and challenges in machining. We are committed to staying at the forefront of these developments, continuously investing in research and development, and upgrading our equipment and skills. By embracing innovation and adapting to the changing needs of the market, we aim to provide even more advanced, precise, and reliable CNC milling services for complex metal and plastic parts in the future.