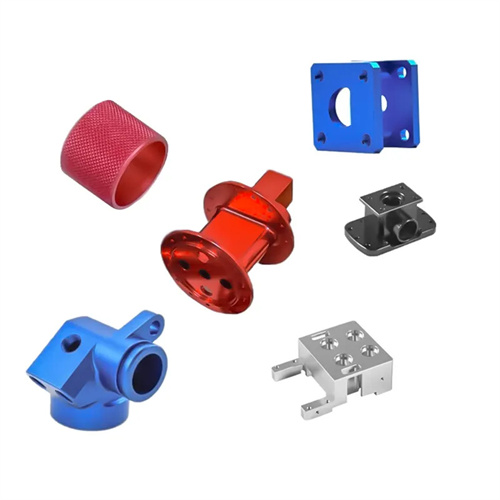

Stainless Steel: The Preferred Material in Our CNC Turning Services

In our CNC Turning Services, stainless steel stands as the preferred material for crafting nonstandard components, and for good reason. Stainless steel offers a remarkable combination of properties that make it ideal for a wide range of applications. Its excellent corrosion resistance ensures that components can withstand harsh environments, whether it’s exposure to moisture, chemicals, or extreme temperatures. This characteristic is crucial for industries such as aerospace, medical, and marine, where parts need to maintain integrity over long periods. Additionally, stainless steel provides high strength and durability, allowing for the creation of robust nonstandard components that can endure heavy loads and rigorous use. Different grades of stainless steel, like 304 and 316, have specific properties that we leverage depending on the component’s requirements. For example, 316 stainless steel, with its enhanced resistance to chloride corrosion, is often chosen for marine – related nonstandard parts. Our in – depth knowledge of stainless steel grades and their characteristics enables us to select the most suitable material for each project, ensuring the quality and performance of the components produced through our CNC Turning Services.

Advanced Equipment in Our CNC Turning Services for Nonstandard Components

Our CNC Turning Services for nonstandard stainless steel components are powered by a fleet of advanced equipment. We have invested in state – of – the – art CNC turning machines, including multi – axis models and live – tooling lathes. These machines are designed with high – precision linear guides and ball screws, which provide smooth and accurate movement of the cutting tool, essential for machining complex nonstandard geometries. The high – torque spindles in our equipment can handle the tough nature of stainless steel, enabling efficient material removal even for large – scale components. Our live – tooling lathes offer the versatility to perform multiple operations, such as milling, drilling, and threading, in a single setup. This reduces production time and improves the precision of components with intricate features. Coupled with advanced computer – aided design (CAD) and computer – aided manufacturing (CAM) software, our equipment allows us to generate optimized toolpaths, taking into account the specific design and material properties of each nonstandard component. This advanced setup ensures that we can meet the most challenging requirements of our clients in the production of custom stainless steel parts through our CNC Turning Services.

Customization Process in Our CNC Turning Services

The customization process is at the heart of our CNC Turning Services for nonstandard stainless steel components. It all starts with a detailed consultation with our clients. We work closely with them to understand their specific needs, the intended application of the component, and any unique design requirements. Using CAD software, our experienced designers create detailed 3D models of the nonstandard components, incorporating all the necessary features and specifications. These models are then refined through continuous communication with the client to ensure complete satisfaction. Once the design is finalized, our CAM software generates the machining instructions for our CNC turning machines. Our skilled operators then set up the machines, carefully selecting the appropriate cutting tools and adjusting the machining parameters based on the component’s design and the properties of the stainless steel. Throughout the process, we maintain open lines of communication with the client, providing updates and addressing any concerns. This comprehensive customization process in our CNC Turning Services ensures that each nonstandard stainless steel component is tailored precisely to our clients’ needs.

Precision Assurance in Our CNC Turning Services for Nonstandard Components

Precision is non – negotiable in our CNC Turning Services for nonstandard stainless steel components. Nonstandard parts often have unique and strict tolerance requirements, and even the slightest deviation can render a component unusable. To ensure precision, our CNC turning machines are equipped with high – resolution encoders that continuously monitor the position of the cutting tool and the rotation of the spindle. This real – time feedback allows for immediate adjustments to maintain accuracy. We use advanced cutting tools with specialized coatings designed for machining stainless steel. These tools can withstand the high cutting forces and temperatures generated during the process while maintaining sharp edges for precise cuts. Our CAM software generates highly accurate toolpaths, taking into account factors such as the component’s complex geometry, material hardness, and cutting forces. During the turning process, in – process measurements are carried out using precision instruments like digital calipers, micrometers, and laser measuring devices. These measurements enable us to make real – time adjustments to the machining parameters, ensuring that the final component meets the exacting specifications. This commitment to precision in our CNC Turning Services guarantees that our nonstandard stainless steel components fit and function perfectly in their intended applications.

Rigorous Quality Control in Our CNC Turning Services

Rigorous quality control is an integral part of our CNC Turning Services for nonstandard stainless steel components. We have established a comprehensive quality management system that adheres to international standards, such as ISO 9001. Our quality control process begins with the inspection of raw materials. We verify the chemical composition, mechanical properties, and certifications of the stainless steel to ensure its suitability for the project. During the machining process, in – process inspections are carried out at regular intervals to monitor tool wear, surface finish, and dimensional accuracy. Any signs of deviation from the specified standards are immediately addressed, either by adjusting the machining parameters or replacing the cutting tool. After machining, each component undergoes a series of final inspections. We use coordinate measuring machines (CMMs) to verify the overall dimensions and geometries of the component with high precision. Non – destructive testing methods, such as ultrasonic testing, may also be employed to check for internal defects. By maintaining strict quality control at every stage, we can provide our clients with high – quality, reliable nonstandard stainless steel components produced through our CNC Turning Services.

Future Prospects of Our CNC Turning Services for Nonstandard Components

As we look to the future, we are excited about the prospects of our CNC Turning Services for nonstandard stainless steel components. The demand for custom – made parts is on the rise, driven by the growth of industries such as renewable energy, advanced manufacturing, and robotics. Technological advancements, such as the integration of artificial intelligence (AI) and the Internet of Things (IoT), present new opportunities for our factory. AI algorithms can analyze machining data in real – time, optimize toolpaths, and predict tool wear, leading to increased efficiency and reduced production costs. IoT – enabled machines will allow for remote monitoring and predictive maintenance, minimizing downtime and improving overall productivity. We are committed to staying at the forefront of these developments, continuously investing in research and development, and upgrading our equipment and skills. By embracing innovation and adapting to the changing needs of the market, we aim to provide even more advanced, precise, and reliable CNC Turning Services for nonstandard stainless steel components, contributing to the success of our clients’ projects in the future.