Unmatched Efficiency in Custom Precision Machining Parts Production

As a China – based factory specializing in custom precision machining parts and rapid prototype machining parts, our efficiency is a key differentiator. Our well – organized production lines and advanced manufacturing equipment allow us to complete projects in record time. With a large – scale production setup, we can handle multiple orders simultaneously without compromising on quality.

The integration of modern CNC machines and automated systems streamlines the machining process. For rapid prototype machining parts, we leverage 3D printing technologies and rapid tooling methods, which can transform a design concept into a physical prototype within days. In the case of custom precision machining parts, our optimized machining algorithms and high – speed cutting tools reduce machining time significantly. This efficiency not only benefits our clients who need quick turnarounds for product development but also enables us to stay competitive in the global market, delivering high – quality parts at a rapid pace.

Diverse Capabilities for Custom Precision Machining Parts

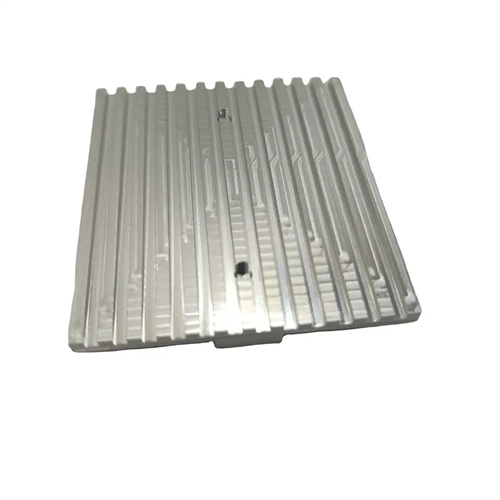

Our factory boasts a wide range of capabilities when it comes to custom precision machining parts. We are proficient in various machining techniques, including milling, turning, EDM (electrical discharge machining), and grinding. This versatility allows us to produce parts with different geometries, sizes, and material requirements. Whether it’s a small, intricate component made of titanium or a large – scale aluminum part with strict tolerance requirements, we have the expertise and equipment to get the job done.

For rapid prototype machining parts, we can create functional models, appearance models, and engineering prototypes. We use different materials such as plastics, metals, and composites, depending on the specific needs of the project. Our skilled technicians and engineers work closely together to ensure that each custom precision machining part and rapid prototype machining part meets the highest standards of quality and functionality, providing our clients with reliable and accurate components for their products.

Cost – Advantageous Custom Precision Machining Parts

One of the significant advantages of our China factory for custom precision machining parts and rapid prototype machining parts is the cost – effectiveness. Our strategic location in China, with access to a large pool of skilled labor and a well – developed supply chain, enables us to keep production costs in check. We source raw materials in bulk from local suppliers, which helps us obtain competitive prices without sacrificing quality.

In addition, our efficient production processes and high – volume production capabilities allow us to achieve economies of scale. For rapid prototype machining parts, we offer cost – saving solutions by choosing the most appropriate manufacturing method based on the design complexity and quantity required. For custom precision machining parts, our optimized machining strategies reduce material waste and labor hours, translating into lower costs for our clients. This cost – advantage makes our services accessible to a wide range of businesses, from startups to large – scale enterprises.

Quality – Driven Custom Precision Machining Parts

Quality is at the heart of everything we do with custom precision machining parts and rapid prototype machining parts. Our factory adheres to strict quality control standards throughout the production process. We start by carefully selecting raw materials, conducting thorough inspections to ensure they meet the required specifications. During machining, our state – of – the – art equipment is equipped with advanced monitoring systems that detect any potential issues in real – time.

After production, each part undergoes a series of rigorous tests. For custom precision machining parts, we use high – precision measuring instruments like coordinate measuring machines (CMMs) to verify dimensions, surface roughness, and geometric tolerances. For rapid prototype machining parts, we conduct functional and structural tests to ensure they perform as expected. Our quality control team is trained to meet international standards, ensuring that every part leaving our factory is of the highest quality, giving our clients peace of mind.

Customized Services for Custom Precision Machining Parts

We understand that every client has unique requirements for custom precision machining parts and rapid prototype machining parts. That’s why we offer highly customized services. Our team of experienced engineers and designers works closely with clients from the initial concept stage. We use computer – aided design (CAD) and computer – aided manufacturing (CAM) software to translate clients’ ideas into detailed production plans.

Whether it’s modifying an existing design, creating a part from scratch, or optimizing a prototype for mass production, we are committed to meeting clients’ specific needs. We also provide comprehensive after – sales services, including technical support, part modification, and re – production if necessary. This personalized approach to custom precision machining parts and rapid prototype machining parts has earned us the trust and loyalty of our clients worldwide, who know they can rely on us for their manufacturing needs.

Innovation – Focused Custom Precision Machining Parts

In the ever – evolving manufacturing landscape, our China factory remains focused on innovation for custom precision machining parts and rapid prototype machining parts. We continuously invest in research and development, exploring new materials, machining techniques, and manufacturing processes. For example, we are actively researching the application of new composite materials in custom precision machining parts to enhance performance and reduce weight.

We also embrace emerging technologies such as artificial intelligence and the Internet of Things (IoT) in our production lines. AI – driven process optimization can improve machining accuracy and efficiency, while IoT – enabled monitoring systems can provide real – time data for better production management. By staying at the forefront of innovation, we aim to offer our clients cutting – edge solutions for custom precision machining parts and rapid prototype machining parts, helping them gain a competitive edge in their respective markets.