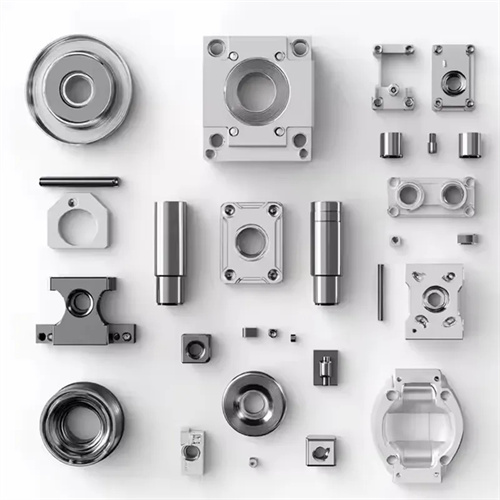

Our Proficient Custom Precision Machining of Aluminum Parts

Since 2017, we have been at the forefront of custom precision machining parts, with a particular focus on 5052, 5083, 6061, 6082, and 7075 aluminum parts. Our factory is equipped with state – of – the – art CNC machines that can handle the unique characteristics of these aluminum alloys with utmost precision.

For instance, the 6061 aluminum alloy, known for its excellent corrosion resistance and weldability, is a popular choice for various applications. Our advanced milling and turning processes can shape 6061 aluminum into intricate components with tight tolerances. The 7075 aluminum, despite its lower corrosion resistance compared to 6061, offers high strength – to – weight ratio. We have mastered the techniques to machine 7075 aluminum into parts that are suitable for high – stress applications. Over the years, we have continuously upgraded our equipment and skills to ensure that each custom precision machining part made from these aluminum alloys meets the highest industry standards.

Diverse Applications of Our Custom Precision Aluminum Parts

Our custom precision machining parts crafted from 5052, 5083, 6061, 6082, and 7075 aluminum alloys have found their way into a wide range of industries. In the automotive sector, 6061 aluminum parts are used in engine components and suspension systems due to their strength and corrosion resistance. The 5052 aluminum, with its good formability and excellent corrosion resistance, is ideal for automotive panels and body parts.

In the aerospace industry, 7075 aluminum parts are crucial for aircraft structures and components where high strength and lightweight properties are essential. The 5083 aluminum, known for its outstanding corrosion resistance in marine environments, is used in the construction of boats and offshore platforms. In the electronics industry, 6082 aluminum parts are used in heat sinks and enclosures due to their good thermal conductivity and machinability. Our ability to produce high – quality custom precision parts has made us a reliable partner for companies across these diverse industries.

Cost – Effective Solutions for Custom Precision Aluminum Parts

Over the period from 2017 to 2024, we have been committed to providing cost – effective solutions for our custom precision machining parts made from 5052, 5083, 6061, 6082, and 7075 aluminum. We source raw materials in bulk directly from reliable suppliers, which allows us to obtain competitive prices without sacrificing quality.

Our optimized production processes, including efficient machining strategies and advanced programming of CNC machines, help reduce material waste and labor hours. For example, by carefully planning the tool paths in machining 6061 aluminum parts, we can minimize the number of passes and thus save machining time. In addition, our high – volume production capabilities enable us to achieve economies of scale. Whether it’s a small – batch order of custom 5083 aluminum parts for a prototype or a large – scale production of 7075 aluminum components for an aerospace project, we ensure that our clients get the best value for their money.

Rigorous Quality Control for Custom Precision Aluminum Parts

Quality has been our top priority in the custom precision machining of 5052, 5083, 6061, 6082, and 7075 aluminum parts from 2017 to 2024. We start by meticulously inspecting the incoming aluminum raw materials to ensure they meet the required specifications. Our in – house quality control team uses advanced testing equipment to check for material composition and mechanical properties.

During the machining process, our CNC machines are equipped with real – time monitoring systems that detect any deviations in machining parameters. After production, each part undergoes a series of rigorous inspections. We use high – precision measuring instruments such as coordinate measuring machines (CMMs) to verify the dimensions, surface roughness, and geometric tolerances of the parts. For parts made from corrosion – resistant aluminum alloys like 5052 and 5083, we also perform corrosion resistance tests. This comprehensive quality control process ensures that every custom precision machining part leaving our factory is of the highest quality.

Customized Services for Your Aluminum Part Needs

Understanding that each client has unique requirements for custom precision machining parts, we have been offering highly customized services since 2017. Our team of experienced engineers and designers work closely with clients from the initial concept stage. When dealing with 5052, 5083, 6061, 6082, and 7075 aluminum parts, we use computer – aided design (CAD) and computer – aided manufacturing (CAM) software to translate clients’ ideas into detailed production plans.

Whether a client needs a modification of an existing aluminum part design, a completely new part from scratch, or advice on the best aluminum alloy to use for a specific application, we are there to help. For example, if a client is unsure whether to use 6061 or 7075 aluminum for a particular project, our experts can provide detailed technical advice based on factors such as strength requirements, corrosion resistance needs, and cost considerations. We also offer comprehensive after – sales services, including technical support, part modification, and re – production if necessary.

Innovation – Driven Custom Precision Aluminum Machining

From 2017 to 2024, we have been constantly driven by innovation in the custom precision machining of 5052, 5083, 6061, 6082, and 7075 aluminum parts. We invest heavily in research and development to explore new machining techniques and materials. For instance, we are researching new ways to improve the surface finish of 7075 aluminum parts without sacrificing their strength.

We also embrace emerging technologies such as artificial intelligence (AI) and the Internet of Things (IoT) in our production lines. AI – driven process optimization can predict and prevent potential machining errors in real – time, while IoT – enabled monitoring systems can provide us with valuable data for better production management. By staying at the forefront of innovation, we aim to offer our clients cutting – edge solutions for their custom precision aluminum part needs, helping them gain a competitive edge in their respective markets.