Advanced Techniques in Custom Precision Machining of Prototype Aluminum Parts

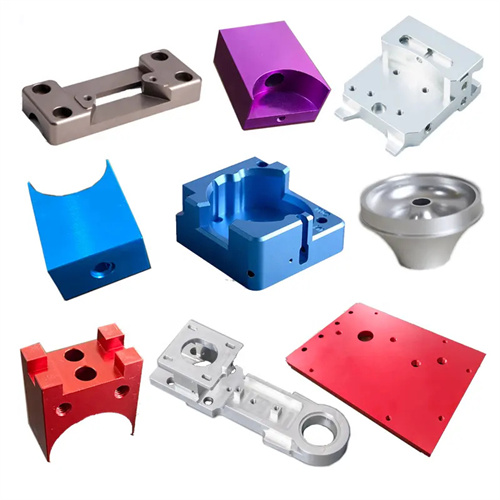

We are at the forefront of custom precision machining parts, especially when it comes to prototype aluminum parts with red anodizing. Our state – of – the – art machining facilities house advanced CNC machines that are specifically calibrated to handle the unique characteristics of aluminum. This enables us to craft highly detailed and accurate prototype parts, meeting the most stringent design requirements.

The process begins with meticulous material selection, ensuring that only high – grade aluminum alloys are used. Our skilled technicians then utilize cutting – edge machining software to program the CNC machines, allowing for the creation of complex geometries with pinpoint precision. After machining, the red anodizing process adds a layer of both functionality and aesthetics. Anodizing not only enhances the corrosion resistance of the aluminum but also provides a durable and vibrant red finish. We continuously refine our machining and anodizing techniques through research and development, ensuring that each custom precision machining part we produce is a showcase of our technical expertise and innovation.

Versatile Applications of Our Custom Precision Prototype Aluminum Parts

Our custom precision machining parts, specifically prototype aluminum parts with red anodizing, have a wide range of applications across multiple industries. In the consumer electronics sector, these parts are ideal for creating stylish and durable casings for smartphones, tablets, and other devices. The red anodized finish not only gives products an eye – catching appearance but also offers protection against daily wear and tear.

In the automotive industry, prototype aluminum parts are crucial for developing new components. The red anodizing can be used to mark test parts or for aesthetic purposes in concept vehicles. Additionally, in the aerospace field, our precision – machined aluminum prototypes play a vital role in the initial stages of component development. The lightweight nature of aluminum, combined with the enhanced durability provided by red anodizing, makes these parts perfect for testing and validating designs before full – scale production. Whether it’s for product development, concept models, or functional testing, our custom precision machining parts meet the diverse needs of various industries.

Cost – Effective Production of Custom Precision Prototype Aluminum Parts

Despite the high – end nature of custom precision machining parts, particularly prototype aluminum parts with red anodizing, we are committed to offering cost – effective solutions. We achieve this through efficient production planning and optimized resource utilization. By purchasing aluminum raw materials in bulk, we can secure favorable prices without sacrificing quality.

Our advanced CNC machines are highly productive, reducing labor costs through faster machining cycles. We also streamline the anodizing process by carefully managing batch sizes and production schedules. This allows us to minimize energy consumption and material waste during the anodizing stage. Additionally, our in – house expertise in process optimization enables us to find the most economical ways to achieve the desired precision and red anodized finish. We balance quality and cost, ensuring that our custom precision machining parts are accessible to a wide range of clients, from startups working on innovative prototypes to established companies with large – scale projects.

Rigorous Quality Control for Custom Precision Prototype Aluminum Parts

Quality is the cornerstone of our custom precision machining parts, especially those involving prototype aluminum parts with red anodizing. From the moment the aluminum raw materials arrive at our facility, we implement a strict quality control process. We conduct thorough inspections to verify the material’s chemical composition, mechanical properties, and dimensional accuracy.

During the machining process, our CNC machines are equipped with real – time monitoring systems that detect any deviations in machining parameters. After machining, the parts undergo a meticulous red anodizing process, where factors such as anodizing time, temperature, and electrolyte concentration are precisely controlled to ensure a consistent and high – quality finish. Once the anodizing is complete, each part is rigorously tested. We use high – precision measuring instruments to check dimensions and surface roughness, and perform corrosion resistance tests to ensure the effectiveness of the anodized layer. Our unwavering commitment to quality assurance guarantees that every custom precision machining part meets the highest industry standards.

Tailored Solutions for Custom Precision Prototype Aluminum Parts

We understand that each client has unique requirements for custom precision machining parts, especially when it comes to prototype aluminum parts with red anodizing. Our team of experienced engineers and designers work closely with clients from the initial concept stage. Using computer – aided design (CAD) and computer – aided manufacturing (CAM) software, we translate clients’ ideas into detailed machining plans.

Whether a client needs a simple modification to an existing prototype design or a completely new part from scratch, we have the expertise to deliver. For example, if a client requires a specific shade of red for the anodized finish or a unique internal structure for the aluminum part, our team can optimize the machining and anodizing processes to meet these exact requirements. We also offer a variety of aluminum alloys and anodizing options, allowing clients to customize their parts according to functional, aesthetic, and budgetary needs. Our dedication to providing personalized solutions has earned us the trust and loyalty of clients across different industries.

Innovation – Driven Future for Custom Precision Prototype Aluminum Parts

Looking towards the future, we are dedicated to driving innovation in the production of custom precision machining parts, specifically prototype aluminum parts with red anodizing. We are constantly researching and adopting new technologies to improve our manufacturing processes. For instance, we are exploring new anodizing techniques that can offer more vibrant and durable red finishes, as well as better control over color consistency.

In machining, we aim to integrate more automation and artificial intelligence into our CNC processes. AI – driven systems can optimize machining parameters in real – time, while automation can enhance the efficiency and precision of part production. Additionally, we are investigating new aluminum alloys with improved properties that can further expand the capabilities of our custom precision machining parts. By staying at the forefront of technological advancements, we strive to continue providing our clients with cutting – edge prototype aluminum parts that meet the evolving demands of the market and help our customers stay competitive.