Cutting – Edge Capabilities in Metal Steel CNC Machining

As a leading force in China’s manufacturing industry, we take great pride in our cutting – edge capabilities in high – precision 3/4/5 axis custom metal steel CNC machining. Our manufacturing facilities are outfitted with state – of – the – art CNC machines that are meticulously calibrated to handle various types of steel, from common carbon steel to high – performance alloy steel, with exceptional precision. The 3 – axis machines lay the foundation for basic machining operations, while our 4 – and 5 – axis CNC machines bring a new level of flexibility and accuracy.

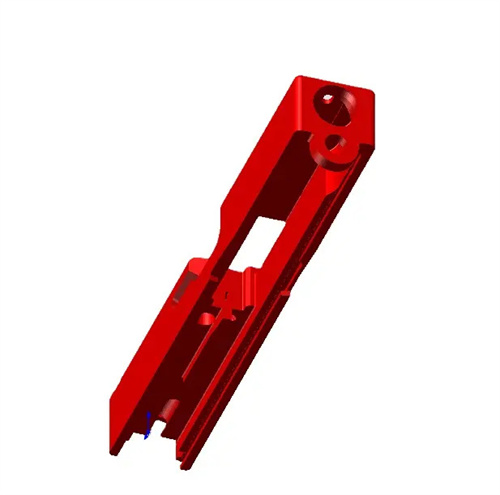

With 4 – axis machining, we can rotate the workpiece during the machining process, enabling the creation of complex geometries that are difficult to achieve with 3 – axis machines. The 5 – axis CNC machining, on the other hand, allows for simultaneous movement of five axes, providing the ability to approach the workpiece from any angle. This multi – axis machining technology empowers our skilled technicians to produce intricate parts with tight tolerances, such as aerospace engine components and high – end mold inserts made of steel. We continuously invest in upgrading our equipment and software, ensuring that we remain at the forefront of metal steel CNC machining technology.

Diverse Applications of Our Metal Steel CNC Machined Parts

Our high – precision 3/4/5 axis custom metal steel CNC machined parts find extensive applications across a wide range of industries. In the aerospace sector, steel parts are crucial for structural components, landing gear, and engine parts. The strength and durability of our precision – machined steel parts, achieved through advanced 5 – axis CNC machining, ensure that these components can withstand the extreme conditions of flight, including high altitudes, intense vibrations, and significant temperature variations.

In the automotive industry, our steel CNC machined parts are used in engine blocks, transmission systems, and suspension components. The 4 – axis machining capabilities allow us to produce parts with optimized weight – strength ratios, enhancing vehicle performance and fuel efficiency. Additionally, in the energy industry, from power generation equipment to oil and gas extraction machinery, our steel parts play a vital role. The precision machining ensures a perfect fit and reliable operation, even in harsh environments. Whether it’s for high – tech aerospace applications or everyday automotive products, our metal steel CNC machined parts meet the diverse needs of various industries.

Cost – Efficient Strategies in Metal Steel CNC Machining

Despite the high – end nature of high – precision 3/4/5 axis custom metal steel CNC machining, we are committed to providing cost – efficient solutions. We achieve this through strategic sourcing and optimized production processes. By establishing long – term partnerships with reliable steel suppliers in China, we can source high – quality raw materials at competitive prices. Our large – scale purchasing power allows us to negotiate favorable terms without compromising on the quality of the steel.

In terms of production, our advanced CNC machines are highly productive, reducing labor costs through faster machining cycles. We also implement lean manufacturing principles, minimizing waste in material usage and optimizing the machining sequence. For example, by carefully planning the toolpaths in 5 – axis machining of steel parts, we can reduce the number of tool changes and machining time. Our in – house expertise in process optimization enables us to find the most economical ways to achieve the required precision, making our metal steel CNC machining services accessible to a wide range of clients, from small – scale startups to large – scale industrial giants.

Stringent Quality Assurance in Metal Steel CNC Machining

Quality is the cornerstone of our high – precision 3/4/5 axis custom metal steel CNC machining. From the moment the steel raw materials enter our factory, we implement a strict quality control process. We conduct comprehensive inspections to verify the chemical composition, mechanical properties, and dimensional accuracy of the steel. Our in – house testing laboratories are equipped with advanced instruments, such as spectrometers for chemical analysis and hardness testers for mechanical property evaluation.

During the machining process, our CNC machines are equipped with real – time monitoring systems that detect any deviations in machining parameters, such as cutting speed, feed rate, and tool wear. After machining, each part undergoes a series of rigorous tests. We use high – precision measuring instruments, such as coordinate measuring machines (CMMs), to accurately measure the dimensions, surface roughness, and geometric tolerances of the parts. Non – destructive testing methods, like ultrasonic and magnetic particle inspection, are also employed to detect any internal flaws. Our unwavering commitment to quality assurance ensures that every metal steel CNC machined part leaving our facility meets the highest international standards.

Customized Solutions for Metal Steel CNC Machining

We understand that each client has unique requirements for high – precision 3/4/5 axis custom metal steel CNC machining. Our team of experienced engineers and designers works closely with clients from the initial concept stage. Using computer – aided design (CAD) and computer – aided manufacturing (CAM) software, we translate clients’ ideas into detailed machining plans. Whether a client needs a simple steel part with basic machining requirements or a highly complex component that demands 5 – axis machining, we have the expertise to deliver.

For instance, if a client requires a steel part with specific internal channels and external contours for a specialized industrial application, our team can optimize the machining process, select the appropriate axis configuration (3/4/5 axis), and choose the most suitable type of steel. We also offer a wide range of surface finishing options, from heat treatment to coating, allowing clients to customize their parts according to functional, aesthetic, and environmental needs. Our dedication to providing personalized solutions has earned us the trust and loyalty of clients both in China and around the world.

Innovation – Driven Future of Metal Steel CNC Machining

Looking towards the future, we are dedicated to driving innovation in high – precision 3/4/5 axis custom metal steel CNC machining. We are constantly researching and adopting new technologies to improve our manufacturing processes. For example, we are exploring the use of artificial intelligence (AI) and machine learning algorithms in CNC machining. These technologies can optimize machining parameters in real – time, predict tool wear, and improve the overall efficiency and precision of the process.

We are also investigating new types of steel materials with enhanced properties, such as higher strength – to – weight ratios and better corrosion resistance. Additionally, the integration of the Internet of Things (IoT) in our production lines will enable us to collect and analyze data from our CNC machines, facilitating predictive maintenance and better production management. By staying at the forefront of technological advancements, we strive to continue providing our clients with cutting – edge metal steel CNC machining solutions, helping them maintain a competitive edge in their respective industries.