ISO9001 – Certified Excellence in Metal Steel CNC Machining

We are proud to offer ISO9001 – certified customized machinery part metal steel CNC machining services. The ISO9001 certification is a testament to our unwavering commitment to quality management systems in every aspect of our metal steel CNC machining processes. This globally recognized standard ensures that from the moment raw steel materials enter our facility to the final delivery of the machined parts, every step is meticulously controlled and documented.

Our ISO9001 – compliant quality management system encompasses strict procedures for supplier evaluation, ensuring that we source only high – grade metal steel from reliable vendors. In the machining process, our state – of – the – art CNC machines are regularly maintained and calibrated according to the certified quality standards. This certification not only gives our clients confidence in the quality and reliability of our metal steel CNC – machined parts but also drives us to continuously improve and innovate in our manufacturing processes, making us a trusted partner in the industry.

Advanced Capabilities in Metal Steel CNC Machining

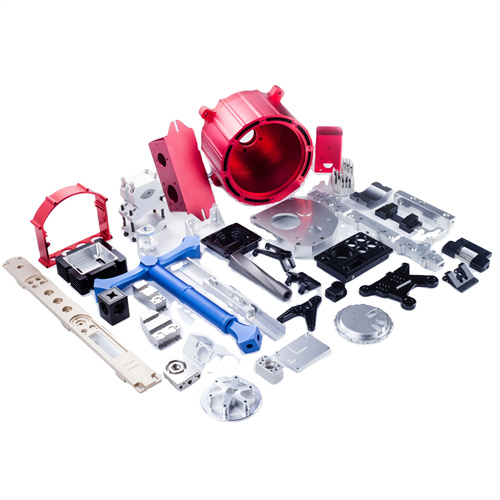

Our ISO9001 – certified facility is equipped with advanced technology for metal steel CNC machining of customized machinery parts. We have a diverse range of 3 – axis, 4 – axis, and 5 – axis CNC machines that can handle various types of steel, including carbon steel, alloy steel, and stainless steel. These machines are capable of producing highly complex geometries with extreme precision, meeting the most demanding requirements of our clients.

For example, when machining components for heavy – duty industrial machinery, our 5 – axis CNC machines can create intricate internal channels and precise external contours in a single setup, reducing errors and improving efficiency. Our skilled technicians and engineers leverage the latest CAD/CAM software to program the machines, ensuring that each metal steel CNC – machined part is manufactured to exact specifications. With continuous investment in new equipment and technology, we stay at the forefront of metal steel CNC machining capabilities, delivering top – quality customized parts for a wide range of machinery applications.

Diverse Applications of Our Metal Steel CNC Machined Parts

Our ISO9001 – certified customized metal steel CNC – machined parts find extensive use across multiple industries. In the automotive sector, we manufacture crucial components such as engine blocks, transmission parts, and suspension components. The precision and durability of our metal steel CNC – machined parts contribute to the overall performance, safety, and longevity of vehicles.

In the aerospace industry, where the highest standards of quality and precision are required, our parts are used in aircraft structural components, engine parts, and landing gear systems. The strict quality control measures ensured by our ISO9001 certification guarantee that these parts can withstand the extreme conditions of flight. Additionally, in the energy, construction, and agricultural industries, our customized metal steel CNC – machined parts play vital roles in machinery operation, providing reliable performance and reducing maintenance costs.

Cost – Effective Solutions in Metal Steel CNC Machining

Despite the high – precision and quality – focused nature of our ISO9001 – certified metal steel CNC machining for customized machinery parts, we are committed to providing cost – effective solutions. Our ISO9001 – compliant processes help us optimize production efficiency and resource utilization. By establishing long – term relationships with steel suppliers, we can source materials at competitive prices without sacrificing quality.

Our advanced CNC machines are highly productive, reducing labor costs through faster machining cycles. Through efficient process planning and the use of advanced nesting software, we minimize material waste during machining. For instance, when producing multiple parts from a single steel sheet, we can optimize the layout to maximize material usage. Our in – house expertise in process optimization, combined with our ISO9001 – certified quality management, allows us to offer cost – effective solutions that meet the budget requirements of our clients while maintaining the highest quality standards.

Tailored OEM Services in Metal Steel CNC Machining

Understanding that each client has unique requirements for customized machinery parts, we offer comprehensive tailored OEM services in metal steel CNC machining. Our ISO9001 – certified quality management system ensures that every customized project is managed with the same level of precision and attention to detail. From the initial design consultation to the final delivery of the parts, our team of experienced engineers and designers work closely with clients.

Using CAD/CAM software, we translate clients’ concepts into detailed machining plans. Whether a client needs a simple modification to an existing part or a completely new design, we have the expertise to deliver. For example, if a client requires parts with specific surface finishes or enhanced mechanical properties, we can recommend appropriate heat treatment processes, coatings, or machining techniques. Our ISO9001 – certified quality control processes ensure that every customized metal steel CNC – machined part meets the client’s exact specifications and expectations.

Future – Oriented Innovation in Metal Steel CNC Machining

As an ISO9001 – certified provider of customized machinery part metal steel CNC machining, we are constantly looking towards the future with a focus on innovation. We are actively researching and adopting new technologies to further enhance our machining capabilities. For example, we are exploring the integration of artificial intelligence (AI) and machine learning algorithms into our CNC machining processes. These technologies can optimize machining parameters in real – time, improving precision and efficiency.

We are also investigating new types of steel materials with improved properties, such as higher strength – to – weight ratios and better corrosion resistance. Additionally, the implementation of the Internet of Things (IoT) in our production lines will enable us to collect and analyze data from our CNC machines, facilitating predictive maintenance and more efficient production management. By staying at the forefront of technological advancements while adhering to our ISO9001 – certified quality standards, we aim to continue providing our clients with cutting – edge, customized metal steel CNC – machined parts that meet the evolving needs of the industry.