How to draw gears, racks, worms, worm wheels, and sprockets

In mechanical drawing, there are strict specifications for the drawing of gears, racks, worms, worm wheels and sprockets. These specifications not only ensure the versatility and readability of the drawings, but also ensure the accuracy of the parts during the manufacturing and assembly process. As one of the most commonly used parts in mechanical transmission, the drawing of gears must comply with national standards and is divided into simplified drawing methods and detailed drawing methods. The simplified drawing method is suitable for general assembly drawings and parts drawings. It only requires drawing the addendum circle, root circle and pitch circle. The pitch circle is represented by a dotted line, the addendum circle and root circle are represented by a thick solid line, and the tooth profile can be omitted. The detailed drawing method is used in situations where the gear tooth shape needs to be expressed in detail. Parameters such as the tooth profile curve, addendum height, root height and pitch need to be accurately drawn. At this time, it is necessary to use gear parameter calculation and drawing tools to ensure the accuracy of the tooth shape.

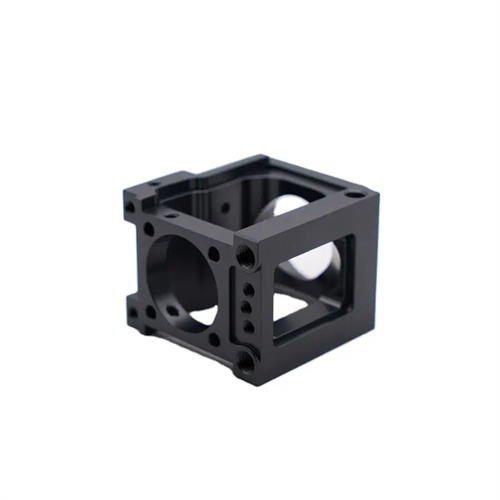

A rack is a special type of gear whose teeth are distributed on a bar-shaped basis. The drawing method is similar to that of a gear but there are also differences. The tooth profile of a rack is a straight line rather than a curve. When drawing, the addendum line, root line, and pitch line correspond to the addendum circle, root circle, and pitch circle of the gear respectively. The pitch line is also represented by a dotted line. Since the tooth directions of the rack are parallel, when drawing the side view of the rack, the straight lines of the tooth profile should remain parallel and evenly distributed, and the pitch must be accurately marked to ensure correct coordination with the meshing gear. In addition, the end structure of the rack (such as mounting holes, locating slots, etc.) must also be drawn according to the actual shape and the relevant dimensions must be marked to ensure accurate installation.

A worm and worm wheel are transmission pairs used to transmit interlaced axial motion and power. Their drawing must reflect the meshing relationship and their respective structural characteristics. The drawing of a worm is similar to that of a thread. The addendum circle, root circle, pitch circle, and direction of the worm’s helix must be drawn. The helix’s direction (left-hand or right-hand) must be clearly indicated. In a cross-sectional view, the addendum and root lines of the worm are represented by thick solid lines, and the pitch line by dashed lines. The worm’s shoulder, keyway, and other structures must also be drawn. The drawing of a worm wheel is similar to that of a gear, but it is important to note that the addendum diameter of a worm wheel is typically larger than its pitch circle diameter. Therefore, the relevant parameters must be accurately calculated and annotated when drawing. When drawing a meshing diagram of a worm and worm wheel, the addendum circle of the worm and the root circle of the worm wheel should be drawn tangentially in the cross-sectional view. Part of the worm wheel’s tooth profile should be obscured by the worm, and the obscured portion should be omitted to clearly depict the meshing.

As a key component in chain drives, the sprocket’s drawing must highlight the shape and distribution of the teeth. Sprocket tooth shape has specific standards and varies depending on the chain model. When drawing, the tooth profile must be drawn according to the corresponding standard dimensions, including the shape of the addendum circle, root circle, pitch circle, and tooth groove. The sprocket’s hub, spokes, and rim structures must be drawn to actual size, and connection structures such as keyways or splines on the hub must be detailed to ensure a reliable connection to the shaft. In the assembly drawing, the meshing portion of the sprocket and chain must be drawn as part of the chain. The chain rollers must accurately match the sprocket’s tooth grooves, and the chain pitch must be equal to the sprocket’s pitch circle pitch to reflect the basic principle of chain drive. Furthermore, parameters such as the number of sprocket teeth, pitch, and roller diameter must be clearly marked in the technical requirements of the drawing to ensure manufacturing accuracy.

Whether it is a gear, rack, worm, worm wheel or sprocket, attention must be paid to the completeness of the dimensioning and technical requirements when drawing. The dimensioning should include the main parameters of the part (such as module, number of teeth, pressure angle, pitch, etc.), structural dimensions (such as diameter, length, width, etc.) and position dimensions (such as center distance of holes, position of keyways, etc.), and the dimensioning must be clear and accurate to avoid duplication or omission. The technical requirements must indicate the material, heat treatment method, surface roughness, form and position tolerances of the parts, such as the tooth surface hardness of the gear, the helix accuracy of the worm, the surface roughness of the sprocket teeth, etc., to ensure the performance of the parts. At the same time, the title bar and detail column of the drawing must be filled in completely, including information such as the part name, quantity, scale, drawing date, etc., so that the drawing has complete technical document attributes and is convenient for production and management.