CNC Milling Services

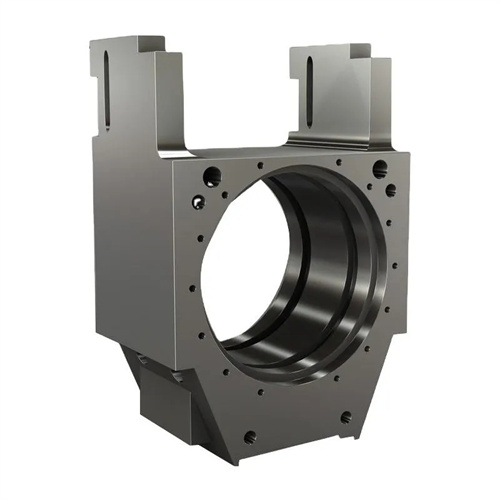

Our CNC Milling Services have significant advantages in high precision and flexibility. The equipped five axis linkage CNC milling machine has a positioning accuracy of ± 0.005mm and a repeated positioning accuracy of ± 0.002mm, which can achieve high-precision machining of complex surfaces, deep cavity structures, and small precision parts. For example, when machining blades for aircraft engines, the tool path can be precisely controlled to ensure that the contour error of the blade surface is less than 0.01mm. At the same time, its high flexibility is reflected in the ability to quickly switch the production of different products by replacing different specifications of cutting tools and adjusting processing programs. Whether it is single piece customization or batch processing, it can be efficiently completed to meet the diverse needs of customers.

Material selection for CNC Milling

In terms of material selection, we offer a wide range of high-quality options. For metal materials, commonly used ones include carbon steel, alloy steel, stainless steel, aluminum alloy, titanium alloy, etc. Carbon steel and alloy steel are suitable for manufacturing mechanical structural components that require high strength and toughness; Stainless steel, with its excellent corrosion resistance, is commonly used in the processing of parts in fields such as food machinery and medical devices; Aluminum alloy is widely used in automotive components and electronic product casings due to its light weight and moderate strength; Titanium alloy has become the preferred material for aerospace and high-end medical equipment due to its high strength, high temperature resistance, and good biocompatibility. In addition to metals, we can also process non-metallic materials such as engineering plastics and composite materials, such as polycarbonate and carbon fiber reinforced composite materials, to meet the special requirements of different industries for material properties. Before being put into production, each material needs to undergo strict quality testing to ensure that its various performance indicators meet international standards and customer requirements.

The production process of CNC Milling

We have established a rigorous and meticulous production process. Firstly, a professional team of engineers uses CAD/CAM software such as SolidWorks and UG to perform 3D modeling and programming based on the drawings or design schemes provided by the customer, converting the design into instruction codes recognizable by the CNC machine tool. Next, the operator fixes the raw material on the workbench and accurately sets the tool parameters through the tool presetter to ensure the accurate starting position of the machining. During the milling process, the real-time monitoring system dynamically monitors and adjusts parameters such as cutting force, spindle speed, and feed rate to prevent machining errors or tool damage caused by abnormal cutting parameters. For complex parts, multiple processes such as rough milling, semi precision milling, and precision milling are often required to gradually remove materials and ensure the dimensional accuracy and surface quality of the parts. After processing, post-processing steps such as deburring and cleaning will also be carried out to ensure that the product meets delivery standards.

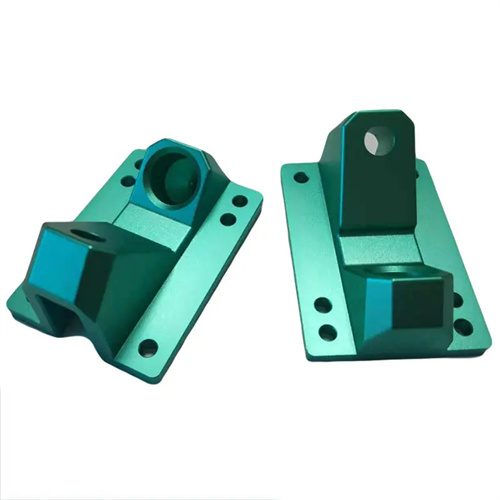

Surface treatment of CNC Milling

We offer a diverse range of surface treatment processes to enhance the performance and appearance of our products. For metal parts, anodizing treatment can form a dense oxide film on the surface of aluminum alloy, enhancing corrosion resistance and wear resistance, while achieving different color effects through dyeing; Electroplating technology can deposit a layer of metal on the surface of parts, such as chrome plating which can improve surface hardness and smoothness, and zinc plating which enhances rust prevention ability; The spray painting process adopts electrostatic spraying technology, which can evenly adhere the coating, effectively protect the parts from environmental erosion, and give the product diverse appearance colors. For non-metallic materials, we use polishing, sandblasting, chemical coating and other treatment methods to improve surface roughness, enhance surface aesthetics and functionality. Based on the product’s usage environment and customer needs, we will recommend the most suitable surface treatment process to ensure that the product exhibits optimal performance in practical applications.

Dimensional Inspection of CNC Milling

In terms of size inspection, we are equipped with advanced testing equipment and a professional quality inspection team. Using a coordinate measuring instrument to measure the three-dimensional dimensions of parts, the measurement accuracy can reach 0.001mm, which can quickly and accurately obtain dimensional data of various parts of the parts. Whether it is complex spatial surfaces, or small aperture and groove widths, they can be accurately detected. The image measuring instrument is suitable for measuring two-dimensional contours, achieving non-contact measurement of part contour dimensions through high-definition imaging and image processing technology, with high measurement efficiency and reliable accuracy. We strictly follow the ISO 9001 quality management system standard, conduct sampling inspections on each batch of products, and conduct full inspections on key components. During the inspection process, if any dimensional deviation is found to exceed the allowable range, the traceability program will be immediately initiated to analyze the cause and adjust the processing parameters. The product will be reworked until it is qualified, ensuring that every part delivered to the customer meets the quality requirements.

Application of CNC Milling products

Our CNC Milling Services process products that are widely used in multiple fields. In the automotive manufacturing industry, processing key components such as engine cylinder blocks, gearbox housings, and steering knuckles helps improve vehicle performance and optimize quality; In the field of electronic device manufacturing, we produce phone cases, tablet frames, precision connectors, etc. to ensure the exquisite appearance and assembly accuracy of our products; In the field of medical equipment, the processed surgical instruments, medical instrument casings, etc. meet the strict standards of the medical industry with high precision and cleanliness; In addition, it is also applied in industries such as mold manufacturing, mechanical manufacturing, and instrumentation, providing reliable component support for the development of various industries.