In the highly specialized and safety – critical field of medical devices, CNC machining services have emerged as an essential cornerstone, enabling us to manufacture components and products that meet the most stringent requirements of precision, reliability, and biocompatibility. With their computer – controlled precision and the ability to work with a diverse range of materials, these services empower us to create everything from intricate surgical instruments to robust diagnostic equipment parts. From ensuring the accuracy of life – saving procedures to facilitating the development of innovative medical solutions, CNC machining services play an indispensable role in our pursuit of advancing healthcare through high – quality medical devices. They have seamlessly integrated into our manufacturing processes, allowing us to produce medical products that inspire trust and confidence among medical professionals and patients alike.

1. CNC Machining Services: Fabricating Precision Surgical Instruments

One of the primary applications of CNC machining services in the medical field is the fabrication of precision surgical instruments. These instruments demand unparalleled accuracy and durability, as they are directly involved in delicate surgical procedures. We utilize CNC machining to create scalpels, forceps, scissors, and retractors from high – grade materials such as stainless steel and titanium alloys.

For example, in the production of scalpels, CNC – machined blades are crafted with extreme precision. The high – speed and high – accuracy of CNC milling processes ensure that the cutting edges are sharp and consistent, enabling surgeons to make clean incisions with minimal tissue damage. In forceps, CNC – fabricated jaws are designed with precise serrations and dimensions, allowing for a secure grip on tissues without causing excessive trauma. The tight tolerances achieved through CNC machining guarantee that each instrument meets the exacting standards required for surgical use, enhancing the safety and effectiveness of medical procedures.

2. CNC Machining Services: Producing Components for Diagnostic Equipment

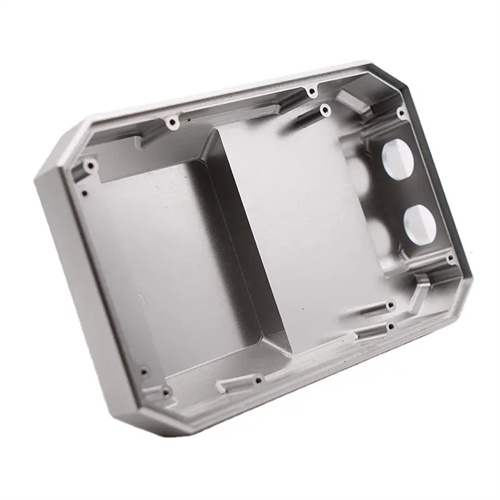

Diagnostic equipment is crucial for accurate medical assessments, and CNC machining services play a vital role in producing its components. We rely on CNC machining to manufacture parts for X – ray machines, ultrasound devices, and MRI scanners from materials like aluminum, stainless steel, and non – magnetic alloys.

In X – ray machines, CNC – machined metal housings and shielding components are essential for protecting patients and medical staff from harmful radiation. The precision of CNC cutting and shaping allows for the creation of complex geometries that fit the internal components of the machine perfectly, ensuring optimal radiation containment. In ultrasound devices, CNC – fabricated transducer components are designed with high – accuracy to ensure clear and detailed imaging. The ability to produce parts with tight tolerances through CNC machining is critical for maintaining the sensitivity and accuracy of diagnostic equipment, enabling healthcare professionals to make informed decisions based on reliable test results.

3. CNC Machining Services: Creating Custom – Designed Medical Implants

The flexibility of CNC machining services allows us to create custom – designed medical implants tailored to the unique needs of individual patients. Whether it’s a personalized orthopedic implant or a cranial plate, CNC machining enables us to bring our designs to life with exceptional precision. We work with biocompatible materials such as titanium and cobalt – chromium alloys to ensure the safety and long – term functionality of the implants.

For example, in orthopedic surgeries, CNC – machined custom knee or hip implants are designed based on the patient’s specific anatomy, obtained through advanced imaging techniques. The precision of CNC machining ensures that the implant fits seamlessly into the patient’s bone structure, promoting faster healing and better mobility. In neurosurgery, custom – made cranial plates fabricated using CNC machining are shaped to match the contours of the patient’s skull, providing optimal protection and support for the brain. These custom – designed implants not only improve patient outcomes but also showcase the potential of CNC machining in personalized medicine.

4. CNC Machining Services: Ensuring Quality and Sterilization Compatibility

In the medical device industry, quality and sterilization compatibility are of utmost importance, and CNC machining services contribute significantly to both aspects. The automated and precise nature of CNC machining reduces human error, ensuring that each component is produced to the same high standards. This consistency in quality is essential for maintaining the reliability of medical devices.

Moreover, CNC – machined components can be designed with features that facilitate sterilization. For example, smooth surfaces and rounded edges, achieved through CNC machining, are easier to clean and sterilize, reducing the risk of infection. In addition, the choice of materials and surface finishes in CNC machining can be optimized to withstand various sterilization methods, such as autoclaving, gamma irradiation, and ethylene oxide sterilization. By ensuring quality and sterilization compatibility, CNC machining services help us produce medical devices that meet the strict regulatory requirements of the healthcare industry.

5. CNC Machining Services: Driving Innovation in Medical Device Design

As the medical device industry continues to evolve, CNC machining services are at the forefront of driving innovation in design. Advanced multi – axis CNC machining technologies, combined with the latest material science advancements, allow us to create more complex, integrated, and functional medical devices.

For example, CNC machining enables the development of minimally invasive surgical instruments with intricate internal channels and articulating mechanisms, reducing patient trauma and recovery times. The ability to quickly prototype using CNC machining also speeds up the product development cycle, allowing us to test and refine new designs more efficiently. Additionally, the use of sustainable materials in CNC machining, along with the recyclability of the machined parts, aligns with the growing demand for environmentally friendly medical solutions. Through continuous exploration and application of CNC machining services, we can drive the development of more innovative, patient – centric, and sustainable medical devices that transform the future of healthcare.