Machining of eccentric parts

An eccentric part refers to a part in which the axis of the outer circle or inner hole of the workpiece is eccentric to the reference axis. It is widely used in machine tools, engines, pumps and other equipment, such as eccentric shafts, eccentric sleeves, crankshafts, etc. The size of its eccentricity directly affects the movement accuracy and working performance of the equipment. The difficulty of turning eccentric parts lies in how to ensure the dimensional accuracy, form and position accuracy of the eccentric part and the accuracy of the eccentricity. Since the eccentric part generates centrifugal force during rotation, it is easy to cause vibration, affecting the processing quality and safety. Therefore, special clamping methods and processing techniques are required. According to the structural characteristics of the eccentric part and the size of the eccentricity, common turning methods include three-jaw self-centering chuck clamping method, four-jaw single-action chuck clamping method, special fixture clamping method and double pin clamping method.

The three-jaw self-centering chuck clamping method is suitable for turning eccentric parts with small eccentricity (generally less than 5mm) and low precision requirements. The principle is to insert a shim of a certain thickness into one of the chuck jaws to create an eccentricity between the workpiece axis and the spindle axis. Calculating the shim thickness is crucial. In theory, the shim thickness is equal to the eccentricity multiplied by 1.5. However, in practice, chuck clamping deformation and workpiece deflection must be considered, and trial cuts are often used to adjust the shim thickness. For example, when machining an eccentric shaft with a 3mm eccentricity, the shim thickness is first calculated to be 4.5mm. After a trial cut, the actual eccentricity is measured. If it is too small, the shim thickness is increased; if it is too large, the shim thickness is reduced until the required value is achieved. The advantages of the three-jaw self-centering chuck clamping method are simple operation and high efficiency, making it suitable for mass production. However, due to the limited centering accuracy of the chuck, the eccentricity accuracy can generally only be controlled within 0.1-0.2mm. Excessive eccentricity should not be too large, otherwise it will lead to loose clamping of the workpiece, vibration, and safety hazards.

The four-jaw single-action chuck clamping method is suitable for turning eccentric parts with large eccentricities and high precision requirements. Its unique feature is that the four jaws can be adjusted individually, allowing precise alignment to ensure that the workpiece’s eccentric axis coincides with the spindle axis. Alignment methods include scribing and dial indicator alignment. Scribing alignment involves marking the axis of the eccentric part and the machining line on the workpiece end face, then adjusting the jaws to align the scribing line with the spindle axis. This method is suitable for applications where precision is not a priority. Dial indicator alignment involves securing a dial indicator to the toolholder with its probe in contact with the workpiece’s outer diameter. The spindle is rotated, and the jaws are adjusted according to the dial indicator reading until the indicator runout equals twice the eccentricity. This method is suitable for applications requiring high precision (eccentricity error can be controlled within 0.02-0.05mm). The advantages of the four-jaw single-action chuck clamping method include wide applicability, the ability to process eccentric parts with a wide range of eccentricities, and high precision. However, the operation is complex, alignment is time-consuming, and efficiency is low, making it suitable for single-piece and small-batch production.

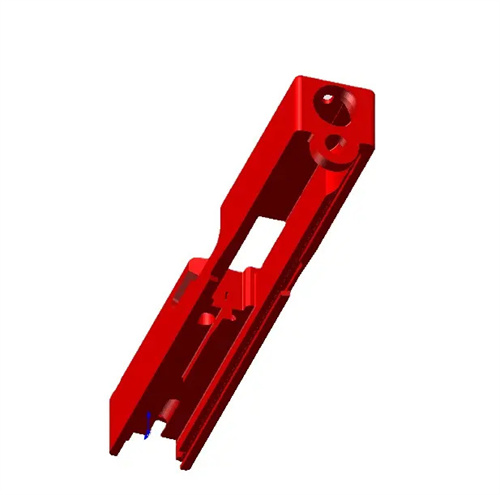

The dedicated fixture clamping method is suitable for mass-production turning of eccentric components. By designing a specialized fixture that matches the workpiece structure, rapid clamping and precise alignment are achieved, improving machining efficiency and accuracy. A dedicated fixture typically consists of a positioning element, a clamping element, and a clamping base. The positioning element ensures that the workpiece’s reference axis aligns with the fixture’s positioning axis, the clamping element securely clamps the workpiece, and the clamping base is connected to the lathe spindle to ensure rotational accuracy. For example, when machining an eccentric sleeve, a dedicated fixture can be designed that uses the workpiece’s inner hole as the positioning reference. A positioning mandrel ensures that the workpiece’s inner hole axis and the fixture’s axis align, thereby achieving the desired eccentricity of the eccentric outer diameter relative to the spindle axis. The advantages of the dedicated fixture clamping method include fast clamping speed, high positioning accuracy (eccentricity error can be controlled within 0.01-0.03mm), and low labor intensity, making it suitable for mass production. However, the fixture design and manufacturing costs are high, and its flexibility is limited. It is therefore only suitable for eccentric components with fixed structures.

The double-thrust clamping method is suitable for turning eccentric shafts with large aspect ratios, particularly workpieces requiring multiple eccentric components (such as crankshafts). The principle is to drill center holes at both ends of the workpiece, corresponding to the axis of the eccentric component. Using double thrust pins, the axis of the eccentric component is aligned with the spindle axis. The key to the double-thrust clamping method is the machining accuracy of the center hole, ensuring that the axis of the center hole coincides with the axis of the eccentric component and that the center holes at both ends are coaxial. During machining, a four-jaw single-action chuck is first used to clamp the workpiece at one end, and a center hole is drilled. The chuck is then reversed and aligned according to the eccentricity, and the center hole at the other end is drilled. The workpiece is then mounted between the double thrust pins and supported by a steady rest to turn the eccentric component. The advantages of the double-thrust clamping method include high positioning accuracy, excellent workpiece rigidity, and a stable machining process. Eccentricity accuracy can reach 0.01-0.02mm, and the phase angle accuracy between multiple eccentric components can be guaranteed. However, its disadvantage is the need for machining the center hole, which complicates the process. It is therefore suitable for the precision machining of long eccentric components.

Key process points and quality control during the turning of eccentric parts are crucial to ensuring machining quality. First, the cutting parameters must be properly selected. Because the eccentric part generates centrifugal force when it rotates, the cutting speed should not be too high. Generally, it is 50-100 m/min, the feed rate is 0.1-0.2 mm/r, and the cutting depth is 0.5-2 mm to reduce vibration. Second, the centrifugal force on the workpiece must be balanced. For workpieces with large eccentricity or heavy weight, balancing blocks can be installed on the chuck or workpiece to reduce the impact of vibration on machining quality. Third, the accuracy of the eccentricity must be strictly controlled. The actual eccentricity is measured through trial cutting. Based on the measurement results, the clamping position or shim thickness is adjusted to ensure that the eccentricity meets the design requirements. Finally, the form and position accuracy of the eccentric part must be checked, such as the roundness and cylindricity of the eccentric outer circle, and its parallelism with the reference axis. These measurements are performed using a dial indicator or roundness tester to ensure that form and position errors are within the allowable range. By properly selecting the clamping method, optimizing the cutting parameters, and strictly controlling the quality, high-precision and high-efficiency turning of eccentric parts can be achieved.