Machining of deep hole workpieces

Deep-hole workpieces typically have a depth-to-diameter ratio (aspect ratio) greater than 5. They are widely used in machine tool spindles, hydraulic cylinders, gun barrels, and other applications. Deep-hole turning is a challenging process in machining due to its deep hole depth, difficult chip evacuation, poor cooling, and poor rigidity. Deep-hole turning requires not only dimensional accuracy (e.g., IT7-IT8) and geometric precision (straightness ≤ 0.01mm/100mm, roundness ≤ 0.005mm), but also controlled surface roughness (Ra ≤ 1.6μm). This requires specialized tools, equipment, and processes. Otherwise, problems such as out-of-tolerance hole diameters, hole wall scratches, and tool breakage can easily occur.

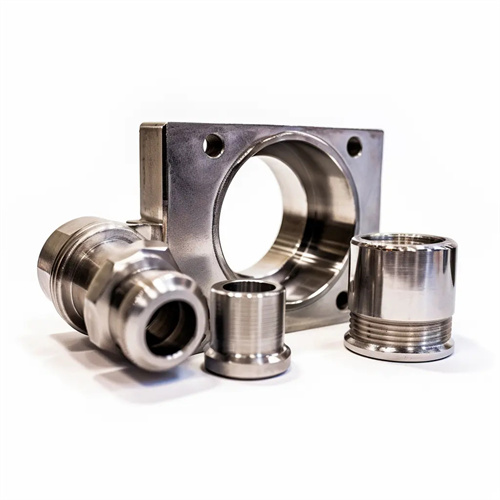

Tool selection for deep-hole turning must meet chip evacuation, cooling, and rigidity requirements. Common tool types include gun drills, BTA deep-hole drills, and ejector drills. Gun drills are suitable for deep holes with diameters of 3-20 mm and aspect ratios up to 100, while BTA deep-hole drills are suitable for deep holes with diameters of 12-150 mm. Tool materials are primarily high-speed steel (such as W6Mo5Cr4V2) and cemented carbide (such as WC-Co). High-speed steel tools offer a sharp cutting edge and are suitable for low-speed machining of plastic materials. Cemented carbide tools offer excellent wear resistance and are suitable for high-speed machining of cast iron or high-strength steel. Tool geometry requires specialized design: a rake angle of 5°-10° to reduce cutting forces, a relief angle of 8°-12° to minimize friction, and a rake angle of -10°–5° to ensure chip discharge toward the bottom of the hole. In addition, the tool needs to be equipped with an internal cooling channel to flush the chips out of the hole through high-pressure cutting fluid (pressure 10-30MPa) and cool the tool at the same time. The cutting fluid is mostly extreme pressure emulsion or mineral oil with moderate viscosity to ensure fluidity and lubricity.

The equipment and clamping method of deep hole turning directly affect the processing accuracy. Special deep hole drilling machines are the preferred equipment. Their spindle and feed system have high coaxiality and rigidity, which can reduce vibration during the processing. If an ordinary lathe is used for modification, a center frame, a steady rest and a cooling pump station need to be installed. The center frame supports the front end of the workpiece, and the steady rest is close to the outer circle of the workpiece to offset the radial cutting force and prevent the workpiece from bending and deforming. The workpiece should be clamped at one end and tightened at the other end. For workpieces with a length-to-diameter ratio of more than 20, auxiliary supports should be added in the middle. The support block material should be wear-resistant cast iron or bronze to avoid scratching the workpiece surface. The straightness of the workpiece needs to be corrected before clamping, and the error should be controlled within 0.1mm/m to ensure that the tool and the workpiece axis are consistent during processing to avoid hole deviation.

Deep-hole turning process parameters must be optimized based on tool type and workpiece material. Cutting speed, feed rate, and depth of cut must balance efficiency and chip evacuation. When gun drilling steel, maintain a cutting speed of 20-40 m/min, a feed rate of 0.01-0.05 mm/r, and a cutting depth equal to 1/3-1/2 the hole diameter. When using BTA deep-hole drilling, the cutting speed can be increased to 50-80 m/min, with a feed rate of 0.1-0.3 mm/r. This higher feed rate promotes strip-like chip removal. The machining process should be performed in stages: roughing removes 70%-80% of the stock, leaving a 0.5-1 mm allowance for finishing. After roughing, the hole diameter and straightness should be inspected. Any deviations can be corrected by adjusting the tool compensation. For finishing, maintain a smaller depth of cut (0.1-0.3 mm) and feed rate (0.05-0.1 mm/r), and use a sharp tool to achieve a high surface quality.

Quality control and chip removal and cooling management in deep-hole turning are crucial for ensuring machining results. Quality inspection requires specialized measuring tools, such as deep-hole internal micrometers and internal diameter dial indicators for hole diameter measurement, laser diameter gauges for straightness, and, for blind holes, measurement of the perpendicularity between the bottom plane and the axis. Poor chip removal is a common problem in deep-hole machining. The chip removal status can be assessed by observing the color and pressure of the cutting fluid. Turbid cutting fluid or a sudden drop in pressure indicates chip blockage, requiring immediate operation and cleaning to prevent tool overheating or tool breakage. The cooling system requires regular maintenance, including filtering impurities (particle size ≤ 5μm) from the cutting fluid and checking pump pressure and flow rate to ensure continuous fluid delivery to the cutting area. Furthermore, a stepped feed method should be employed during machining, with pauses after every 5-10 feed diameters to allow the cutting fluid to fully flush the chips and reduce chip accumulation within the hole. Through rigorous process control and quality inspection, high-precision and efficient machining of deep-hole workpieces can be achieved, meeting the performance requirements of the equipment for deep-hole components.