Cost-Effective Material Selection in CNC Machining Services

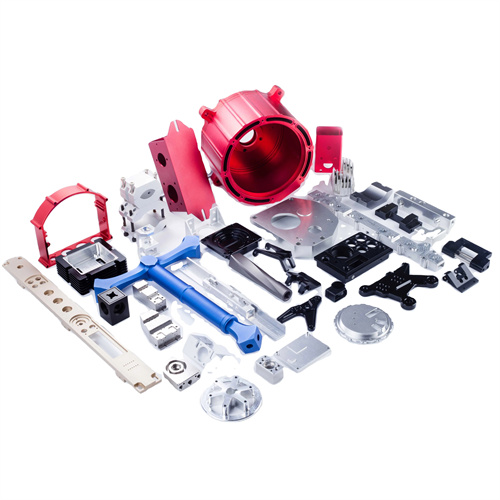

In our pursuit of providing affordable CNC Machining Services for prototypes and low-volume production, material selection plays a pivotal role. We understand that choosing the right material can significantly impact the overall cost without sacrificing quality. For prototypes, we often recommend cost-effective materials like aluminum and engineering plastics. Aluminum is lightweight, easy to machine, and offers good strength-to-weight ratio, making it an ideal choice for various applications. Engineering plastics, on the other hand, are suitable for creating functional prototypes with complex geometries at a lower cost. When it comes to low-volume production, we analyze the product requirements and performance needs to select the most appropriate material. For example, if a part doesn’t require high-temperature resistance, we might opt for a less expensive plastic instead of a high-performance alloy. By carefully considering material properties and costs, we can offer our clients affordable solutions that meet their specific needs in prototype development and small-scale manufacturing.

Streamlined Setup Processes in CNC Machining Services

One of the key factors in making CNC Machining Services affordable for prototypes and low-volume production is streamlining the setup processes. Unlike high-volume production, where the cost per unit can be spread over a large number of parts, prototypes and small batches demand efficient setup procedures to keep costs down. We invest in advanced software and programming tools that enable us to quickly generate machining codes and optimize toolpaths. This reduces the time spent on programming and setup, minimizing labor costs. Additionally, we use modular fixtures and quick-change tooling systems, which allow us to change setups rapidly between different jobs. For instance, when producing a series of prototype parts with varying designs, we can switch from one setup to another in a matter of minutes. By eliminating unnecessary setup time and costs, we can offer more competitive pricing for our CNC machining services, making it accessible for businesses working on prototypes and low-volume production runs.

Optimized Tooling Strategies in CNC Machining Services

To ensure affordability in our CNC Machining Services for prototypes and low-volume production, we focus on optimized tooling strategies. We carefully select the right cutting tools based on the material being machined and the desired surface finish. Using the appropriate tools not only improves machining efficiency but also extends their lifespan, reducing tool replacement costs. For prototypes, we often use standard cutting tools that are readily available and cost-effective. In low-volume production, we analyze the production requirements to determine if custom tools are necessary. If custom tools can significantly reduce machining time or improve part quality, we might invest in them, as the long-term savings can outweigh the initial cost. Moreover, we implement tool management systems that monitor tool wear and optimize tool usage. By maximizing the performance of our cutting tools and minimizing waste, we can keep the machining costs in check, providing affordable solutions for our clients’ prototyping and small-batch production needs.

Flexible Production Scheduling in CNC Machining Services

Flexible production scheduling is another crucial aspect of offering affordable CNC Machining Services for prototypes and low-volume production. We understand that these projects often have tight deadlines and evolving requirements. To accommodate this, we maintain a flexible production schedule that allows us to prioritize jobs based on urgency and client needs. By efficiently allocating machine time and resources, we can complete projects in a timely manner without incurring additional costs due to rushed production. For example, if a client needs a prototype urgently for a product demonstration, we can adjust our schedule to give it top priority. Additionally, we group similar jobs together to take advantage of economies of scale, even in low-volume production. This way, we can share setup costs and optimize machining operations, reducing the overall cost per part. Our flexible production scheduling approach ensures that we can deliver high-quality CNC machining services at affordable prices for both prototype and small-batch production projects.

Value-Added Services in CNC Machining Services

In addition to the core machining operations, our CNC Machining Services for prototypes and low-volume production offer a range of value-added services that contribute to affordability. We provide design for manufacturability (DFM) consultations, where our experts work with clients to optimize their designs for efficient machining. By making minor design changes, we can often reduce machining time and costs significantly. For example, simplifying complex geometries or reducing the number of features can make a part easier and cheaper to produce. We also offer post-processing services such as deburring, polishing, and surface finishing, all under one roof. This eliminates the need for clients to outsource these services, saving them time and money. Moreover, we provide inventory management solutions for low-volume production, ensuring that parts are produced and delivered when needed, without the cost of excessive inventory storage. These value-added services not only enhance the quality of the final product but also make our CNC machining services more cost-effective for our clients.

Future Outlook of Affordable CNC Machining Services

Looking to the future, we are committed to further improving the affordability of our CNC Machining Services for prototypes and low-volume production. With the continuous advancement of technology, we expect to see more automation and artificial intelligence integrated into the machining process. This will not only increase production efficiency but also reduce labor costs, making CNC machining even more accessible. We also anticipate the development of new materials and machining techniques that will offer better performance at lower costs. For instance, the use of composite materials and additive manufacturing in conjunction with CNC machining may open up new possibilities for cost-effective production. As we stay at the forefront of these technological developments and continuously refine our processes, we are confident that we can provide even more affordable, high-quality CNC machining services for prototypes and low-volume production, meeting the evolving needs of businesses across various industries.